Россия лидер продаж легкое газобетонное устройство для производства блоков паровой автомобиль машина панелей

- Категория: >>>

- Поставщик: Henan Fantianliang Machinery & Equipment Co. Ltd.

Сохранить в закладки 1600446918894:

Описание и отзывы

Характеристики

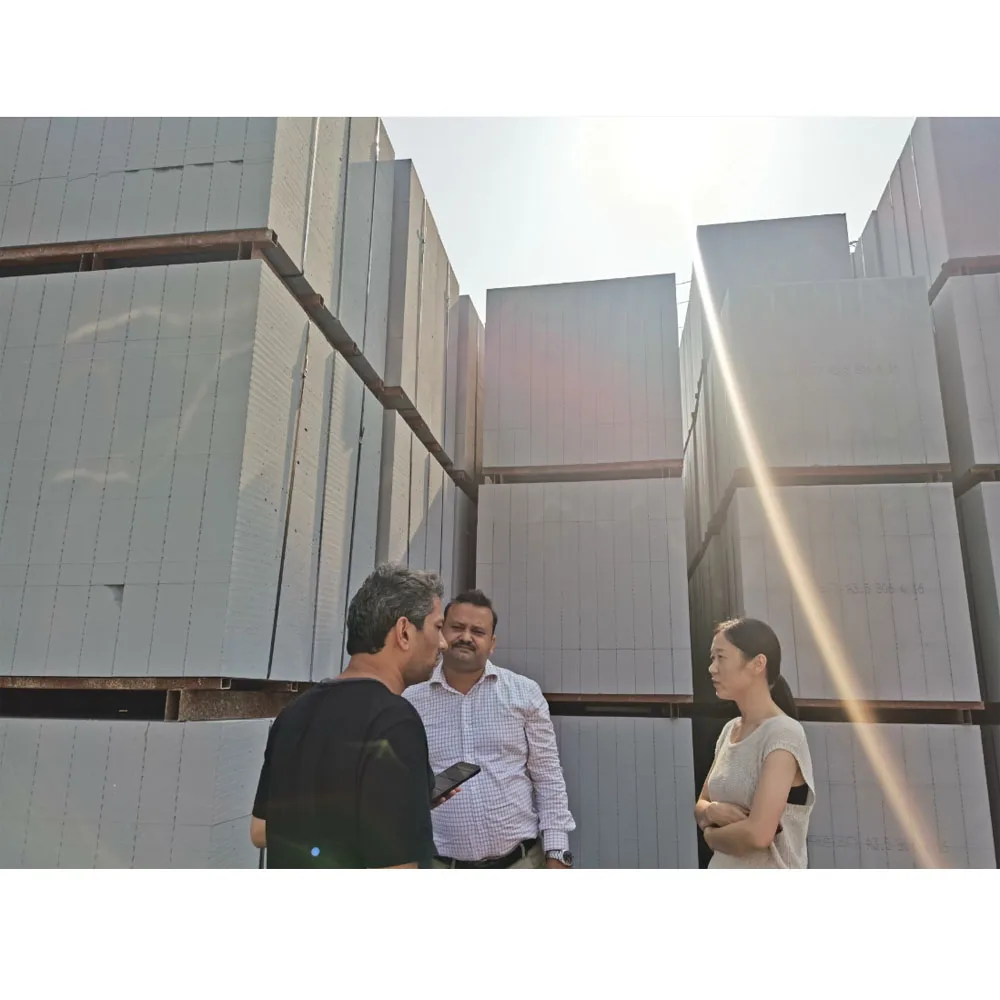

Russia hot sell Lightweight Aerated Concrete AAC Block manufacturing plant ALC Panel Making Machine

AAC block manufacturing machine

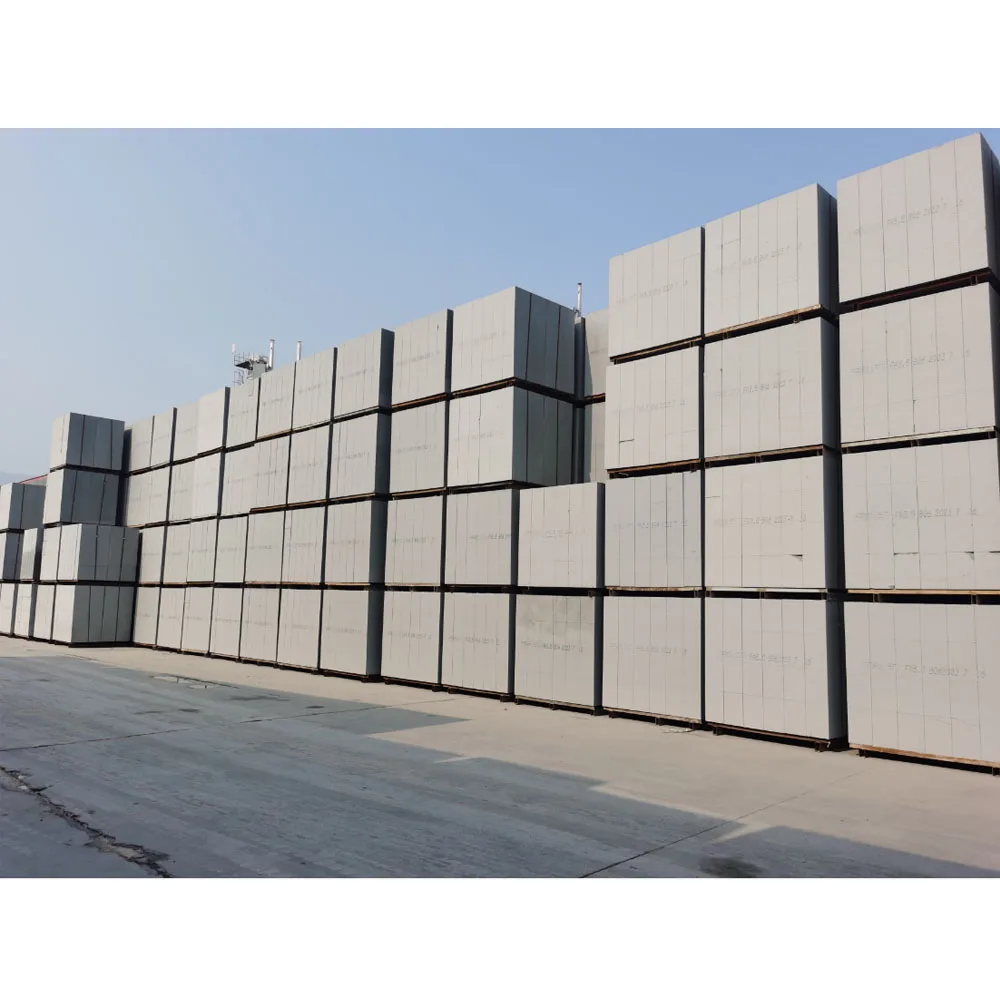

Aerated concrete block equipment (gas filling block equipment) is a new type of building materials machinery equipment. Our company has combined domestic and foreign aerated concrete technology to save resources and protect the environment development. and we can supply complete set of autoclaved aerated concrete plant with 10 000m3, 20 000m3, 50 000m3, 100 000m3, 150 000m3, 200 000m3, 250 000m3, 300 000m3 capacity annually, including plant design, equipments installation, technical instruction, personal training, etc, and also can design and manufacture as per clients' requirement.

1. Raw material: Store the fly-ash (tailings etc), lime and gypsum after milling to the needed fineness (200 mesh)

2. Mixing the fly-ash, cement, lime, gypsum and water in the pot after batching.

3. Promote the slurry temperature to 40-50 degree by steam, and mill with aluminum powder for 1min.

4. Pour the slurry into the mould, and still in the curing room for frothing in 2-2.5h.

5. Cut it in to needed size by the cutter after the slurry approach the cutting intensity, and place the block on the trolley.

6. Autoclaved curing after the trolley enter into the autoclave (vacuum, rise the pressure, keep the pressure, reduce the pressure),keeping the constant pressure 1.2MPa. The whole process needs about 12h.

7. The products out of the autoclave are placed in a stack. We can recycle the scrap and the waste water from the whole production.

2. Raw material for AAC block making machine/ aac plant/aac production line

AAC Aerated concrete is the lightweight artificial stone, adopting the calcareous material and the siliceous material as components, forming the porous structures by the way of chemical gas generation, and obtaining the intensity after autoclaved curing. The calcareous material is mainly lime and cement, the siliceous material generally is industrial waste in China, such as fly-ash, tailings etc, or quartz sand.

3. Dosing & mixing & pouring of AAC

The metered slurry pours into the pouring & mixing machine according to order, and at same time, the dumping device of electronic scale discharges the metered lime and cement powder to pouring and mixing machine. Then the slurry in Slurrying tank after being mixed will be poured into mold box below the Slurrying tank

4. Cutting &marshalling of AAC

After the base reaches to certain hardness for cutting through static stop curing, the overturning crane on cutting and overturning vehicle (10t) hoists and overturns the base to the cutting dolly and demoulds, which overturns the base 90 degrees. Cutting dolly moves to finish transverse and vertical cutting.

The cut base with side plate will be conveyed by marshalling crane to the steam curing dolly and then pulled into autoclaves to steam curing.

5. Steam curing & finished product of AAC

The steam curing time in constant pressure is 4 to 10 hours with the steam pressure 1.3Mpa and temperature around 190°C. Finished products after steam curing are dragged out from autoclave by slow moving hoist, and be lifted by crane to the transport vehicles

6. Retuning, assembling and oiling on Base (side) plate

After conveying the finished products, the bottom (and side) plate on steam curing dolly with the dolly are lifted to lane for returning.

| Annual Capacity(300days) | Power | Daily Capacity | Cycle Time | No. of Autoclaves | plant area (m2) |

| 50,000m³/year | 400KW | 166 m³/day | 8 hours | 2 | 2000 |

| 100,000m³/year | 500KW | 333m³/day | 8 hours | 4 | 2000 |

| 150,000m³/year | 630KW | 500m³/day | 8 hours | 6 | 2500 |

| 200,000m³/year | 720KW | 666m³/day | 8 hours | 8 | 3000 |

| 300,000m³/year | 1186KW | 1000m³/day | 8 hours | 6(D2.85*32.5) | 3500 |

Похожие товары

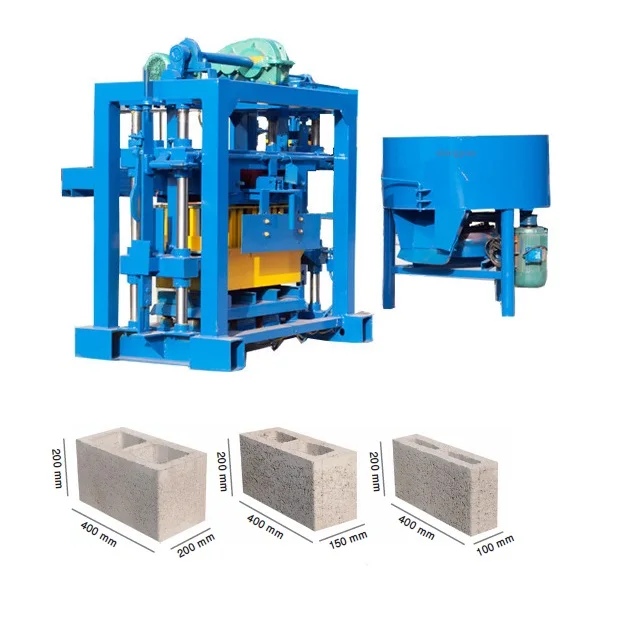

Машина для производства QT4-16 бетонных блоков автоматическая машина Alibabaa Peru из Пакистана небольшая бетононасосная глобальная 4000

Гидравлический бетонный полый блок/цементный кирпич оборудование для производства QT4-18 автоматического газового твердого цементного блока

H1800 производство блочного производства автоматическое оборудование Сделано в Китае

Полые Твердые портативные машины для производства кирпича QT4-15 бетонные блоки асфальтоукладчик и бордюры производственная линия

Автоматическая линия по производству блоков прайс-лист для машины Бетонных Блоков

Устройство для формирования цементных кирпичей цена в Индии QT4-15 по изготовлению силикатного кирпича машины которые используются бетоноукладочная машина

Jzk установка для производства необоженного кирпича QTS2-10 цена в Китае

Новые поступления

Новинки товаров от производителей по оптовым ценам