Цифровой расходомер K24 электронный измеритель расхода дизельных и жидкостей с контролем

- Категория: >>>

- Поставщик: Cangzhou Aistar Metalware Co. Ltd.Cangzhou Ltd.

Сохранить в закладки 1600448420873:

Описание и отзывы

Характеристики

Introduction

The control panel of K 24 Flow meter adopts the concept of modular design, with features of complete function, simple construction, easy operation, etc, which is widely used in petroleum, water and ethyl alcohol etc.

1. TECHNICAL DATA

outlet&inlet size | 1" |

measuring accuracy | ±1% |

repeatability | ±0.5% |

Max working pressure | 20BAR |

standby time | 2 years |

flow-rate range | 10-120L/MIN |

single count | 0.00-999.9 |

total count | 0.00-999999.9 |

measurement unit | L, GAL,PTS,QTS |

single measurement reset | RESET |

2. SET OF MEASUREMENT UNIT

Under the state of standby or current charging display, press the button of CAL and RESET at the same time for 5 seconds. Enter the setting of unit conversion and press the RESET button, choose the measurement unit in turn according to the order of LTR→GAL→PT→QT→LTR, meanwhile the accumulated charging quantity will be displayed based on the conversion of the current measurement unit conversion. Then press the CAL button for 3 seconds to quit the unit conversion setting.

3. Error Coefficient Calibration

Under the state of standby or current charging display, press the button of CAL for 3 seconds, entering the state of error coefficient calibration. Meanwhile when the first digital blinking displays, press the CAL button, then numeric shift (blinking digital displacement), press the RESET button, modify the current blinking figure, from 0 to 9 in turn, then back to 0. The oil pump capacity is less when the digital is increased; vice versa. Press the button CAL for 3 seconds to quit the error coefficient calibration. Back to the state of current charging quantity,and display it as reset. After the error coefficient calibration, demarcate it when there is new measuring pulse input. The range of the error coefficient calibration is from 0.1000 to 9.9999. Press the button of CAL and RESET at the same time to check the coefficient and total accumulated figure.

4. EXAMPLE OF Error Coefficient Adjustment

When the original figure is 1.000, it will display as 100 L oil, the actual oil pump capacity is also 100 L. In case the user wants to reduce 2 L oil, then press the button of CAL for 3 seconds, adjust it to 1.020 according to the Error coefficient Calibration. Then the oil pump capacity will be 98 L. For 96 L, adjust it to 1.040; visa versa.

1) Battery Low Prompt

When the voltage of battery is between 2.2 v to 2.4 v, it will display as LBAT, to remind the user to replace the battery.

5. Maintenance and Preservation

This flow meter needs the battery with life span of at least 9,000 hours (1 year) as the power supply. The short battery life will lead to the battery leakage during working and result in the damage of the flow meter. The standby life of this flow meter is designed as 2 years. Battery replacement every one year is recommended. In case the LCD display becomes dim or the Lbat occurs, it is time to replace the battery. We recommend the users to check the Battery electrode to clear the rusting in case. Take out the battery if the flow meter is not used for a long time.

Похожие товары

Производители прямых продаж высокомощного автомобильного воздушного насоса 12 В портативный автомобильный Электрический воздушный насос Универсальный

Высокопроизводительный Поплавковый переключатель уровня воды улучшенный насос 3A легкий мини

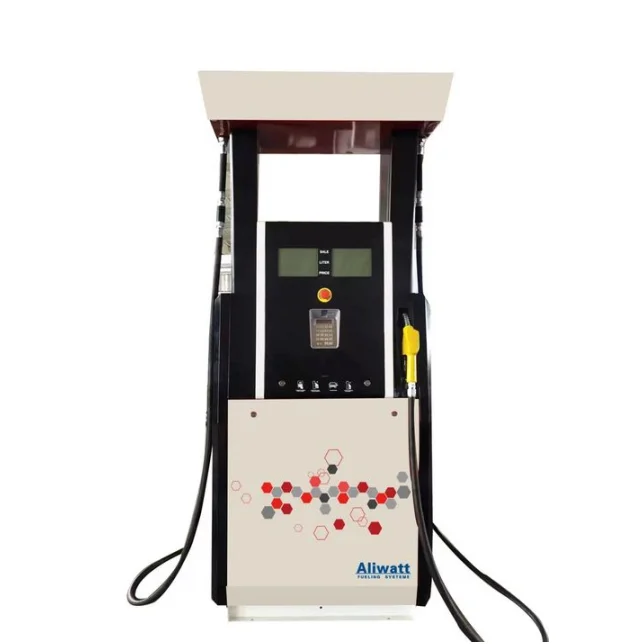

Дозатор топлива 220V/380V 2 сопла Aistar с шестеренчатым насосом/комбинированный насос для топливной станции

400 г автоматический замок подвесной проволочный молоток Магнитный Вертикальный измерительный инструмент строительный перфоратор

2018 Jeep Wrangler безлимитный спортивный внедорожник 4x4 элегантный Подержанный автомобиль с бензиновым топливом готов к быстрой доставке/доставке

Хорошая производительность низкая цена инструменты для садоводства сельскохозяйственная техника 1 6-рядная сеялка

Лидер продаж морская камера из нержавеющей стали с 316 радужной раковины широкоугольная Реверсия азотная инфракрасная готовая к отправке

Новые поступления

Новинки товаров от производителей по оптовым ценам