200 л. С. Водяной охладитель для бетона

- Категория: >>>

- Поставщик: Jinan Mgreenbelt Machinery Co. Ltd.

Сохранить в закладки 1600449587258:

Описание и отзывы

Характеристики

Product Overview

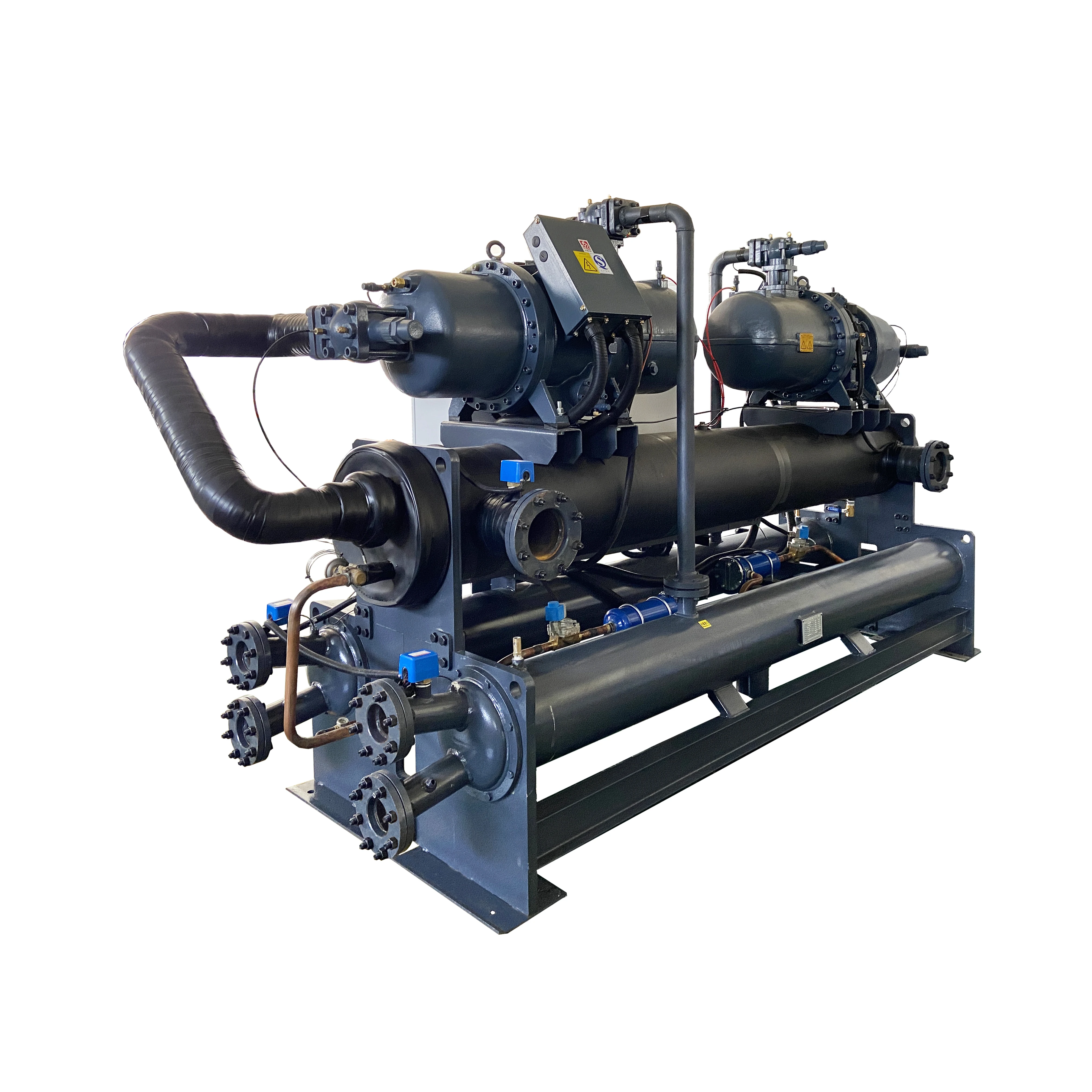

200HP Water Cooled Type Concrete Batching Plant Water Chiller

MGreenbelt is an Industrial Water Chiller Manufacturer!

We can supply the one-station cooling solution for your plastic injection / concrete batching plant /mixing plant / Batching cooling or any other industry process cooling.

For concrete applications, your thermal load capacity needs to be the single most determining factor in your chiller buying decision. Water cooled chillers are normally installed for concrete cooling applications because of their higher cooling efficient and smaller space need.

Water cooled chillers can be installed as well with a cooling tower removing the heat from the water cooled condenser.

MGREENBELT can supply one- station purchase for you, inlcude cooling tower, water tank, and water pumps, customer can get the compelte cooling system from us.

Application Description Of 200HP Water Cooled Type Concrete Batching Plant Water Chiller

For concrete applications, your thermal load capacity needs to be the single most determining factor in your chiller buying decision. Water cooled chillers are normally installed for concrete cooling applications because of their higher cooling efficient and smaller space need.

Water cooled chillers can be installed as well with a cooling tower removing the heat from the water cooled condenser.

MGREENBELT can supply one- station purchase for you, inlcude cooling tower, water tank, and water pumps, customer can get the compelte cooling system from us.

FEATURES AT A GLANCE

1. Water cooled screw water chiller series, the Cooling capacity ranges from 26 ton to 500 Ton;(if you are no convenient to install cooling tower, please choose our air cooled chiller series, or if you need smaller chiller please choose our scroll type chiller series)

2. Temperature control ranges from 0°C to 35°C;the concrete batching plant /mixing plant / Batching cooling use usually need 0 deg C or 1 deg C or 2 deg C or 4 deg C, so this range is enough for concrete batching plant /mixing plant / Batching cooling customer.

3. Shell and tube type evaporator;the closed type heat exchanger can ensure the highest heat exchange efficient, some time suggest to connect a external buffer tank if user side is also a closed loop, the buffer tank can storage some capacity, and save energy for customer.

4. The chilled water flow from 15 m3/h rate up to 300 m3/h;

5. Semi-hermetic screw compressor; we choose Hanbell brand from Taiwan, or Bitzer brand from Germany.

6. Hot gas bypass at compressor & flow switch

7. Custom alarm, phase reversal relay & LCD

8. Easy installation & digital communication, can support WIFI Connection, and RS485 communication.

2. Temperature control ranges from 0°C to 35°C;the concrete batching plant /mixing plant / Batching cooling use usually need 0 deg C or 1 deg C or 2 deg C or 4 deg C, so this range is enough for concrete batching plant /mixing plant / Batching cooling customer.

3. Shell and tube type evaporator;the closed type heat exchanger can ensure the highest heat exchange efficient, some time suggest to connect a external buffer tank if user side is also a closed loop, the buffer tank can storage some capacity, and save energy for customer.

4. The chilled water flow from 15 m3/h rate up to 300 m3/h;

5. Semi-hermetic screw compressor; we choose Hanbell brand from Taiwan, or Bitzer brand from Germany.

6. Hot gas bypass at compressor & flow switch

7. Custom alarm, phase reversal relay & LCD

8. Easy installation & digital communication, can support WIFI Connection, and RS485 communication.

Product name | 200HP Water Cooled Type Concrete Batching Plant Water Chiller | ||||||

Free Solution for Cooled Water Supply | According to your concrete capacity need, we can know hoe many water you need | ||||||

Free Solution Cooling capacity | According to cooled water consume, we will suggest you right cooling capacity | ||||||

One-station purchase service | Concrete chiller, cooling tower, water tank, pumps etc. | ||||||

Concrete chiller cooling capacity | 20 Ton ~500 Ton, ( 90 Kw ~1500 Kw) | ||||||

Cold water flow | 15 m3 per hour ~300 m3 per hour | ||||||

Shipment service | We will arrange the goods to any port you need, accept EXW, FOB , CIF terms | ||||||

Installation | Free one-one support, or send engineers to customer site | ||||||

PRODUCT SPECIFICATIONS

Model/Item | Item | MG-600WD | MG-700WD | MG-930WD | MG-1150 | MG-1250WD | |||||

Cooling Capacity | US Ton | 167.8 | 200.7 | 262.7 | 306.5 | 344.6 | |||||

Kcal /h | 507400 | 607160 | 794640 | 927080 | 1042320 | ||||||

Kw | 590 | 706 | 924 | 1078 | 1212 | ||||||

Power | 3 Phase - 380V -50HZ, or we can make according to different country need | ||||||||||

Refrigerant | Control | Thermostatic expansion valve | |||||||||

Type | R22/ R407c/R134a | ||||||||||

Compressor | Power(KW) | 134 | 156 | 208 | 238 | 268 | |||||

Compressor | Capacity control | 25%-50%-75%-100% | |||||||||

Type | Semi-closed screw type | ||||||||||

Evaporator | Type | Shell and tube | |||||||||

Water flow(m3/h) | 101.1 | 121 | 158.4 | 184.8 | 207.8 | ||||||

Inlet/outlet pipe | DN150 | DN150 | DN 200 | DN200 | DN200 | ||||||

Condenser | Type | Shell and tube | |||||||||

Cooling flow ( m3/h) | 136.5 | 162.5 | 213.5 | 248.2 | 279.1 | ||||||

Protection System | Compressor overheat protection, high/low pressure protection,phase missing/sequence protection, flow rate protection, anti-frozen protection. | ||||||||||

Dimension | mm | 4000*1200*2000 | 4000*1200*2000 | 4400*1400*2200* | 4400*1600*2300 | 4400*1600*2300 | |||||

Weight | kg | 2150 | 2700 | 3600 | 4200 | 4800 | |||||

PRODUCT CONFIGURATION

Features and Advantages

1. Screw water chiller is designed to produce a cooling effect by temperature controlling configured by an energy-efficient compressor, and recirculation pump working on compression principle to regulate the temperature of plastic machining.

2. Screw water chiller is used in injection molding, producing instant cooling to a heated mold for getting a specific product shape, saving energy and power consumption.

3. MGREENBELT brand Plastic Chiller prevents plastic molded products from deforming by releasing plastic internal stress and grain mark, ensuring steadfast and durable product manufacturing.

4. Screw water chiller supports different plastic processing as drying, humidity removal, cooling production, and temperature control configured by its auxiliary design featured with versatile components to perform different operations.

5. Screw water chiller manufactured by MGREENBELT has a variety of benefits for all types of plastic processing

2. Screw water chiller is used in injection molding, producing instant cooling to a heated mold for getting a specific product shape, saving energy and power consumption.

3. MGREENBELT brand Plastic Chiller prevents plastic molded products from deforming by releasing plastic internal stress and grain mark, ensuring steadfast and durable product manufacturing.

4. Screw water chiller supports different plastic processing as drying, humidity removal, cooling production, and temperature control configured by its auxiliary design featured with versatile components to perform different operations.

5. Screw water chiller manufactured by MGREENBELT has a variety of benefits for all types of plastic processing

Successful Project

MGREENBELT has specialized in this line more than 18 years, we have sold the screw water chiller more than 200 countries from all over the world. include the follow industry:

(1).Plastic Industry:

-Presses, Mixing mill, plastic injection molding Chiller;

-Extrusion machine chiller

-Blowing molding machine chiller;

-Thermoforming chiller

-Vacuum forming chiller

(2). Brewery/Winery

-Brewery chiller;-Distillery Chiller;-Winery Chiller;-Fermentation Chiller;-Immersion Chiller;-Cold Storage Chiller;-Glycol chiller.

(3).Chemical Industry

-Acid chiller; -Brine chiller;-Chemical Chiller.- Pharmaceutical chiller;

(4). CNC Cooling

-CNC Chiller;-Laser Chiller;-Plasma Chiller;-Waterjet Cutting chiller; -Welding chiller. -Printing chiller;-Spindle oil cooling chiller

(5).Concrete / Cement

-Batch Cooling -Cement Cooling -Concrete chiller.

(6). Farming

-Dairy milk chiller -Poultry chiller

(7).Food Industry

-Bakery chiller; -Beverage chiller;-Fish Hatchery chiller-Food process cooling chiller -Hydrocooler chiller; -Ice cream chiller; -Yogurt chiller.

(8).Heavy Industrial

-Anodizing chiller;-Biodiesel chiller;-Biogas chiller;-Die Casting chiller;-HAVC Chiller;-Hydraulic chiller-Oil chiller

-Presses, Mixing mill, plastic injection molding Chiller;

-Extrusion machine chiller

-Blowing molding machine chiller;

-Thermoforming chiller

-Vacuum forming chiller

(2). Brewery/Winery

-Brewery chiller;-Distillery Chiller;-Winery Chiller;-Fermentation Chiller;-Immersion Chiller;-Cold Storage Chiller;-Glycol chiller.

(3).Chemical Industry

-Acid chiller; -Brine chiller;-Chemical Chiller.- Pharmaceutical chiller;

(4). CNC Cooling

-CNC Chiller;-Laser Chiller;-Plasma Chiller;-Waterjet Cutting chiller; -Welding chiller. -Printing chiller;-Spindle oil cooling chiller

(5).Concrete / Cement

-Batch Cooling -Cement Cooling -Concrete chiller.

(6). Farming

-Dairy milk chiller -Poultry chiller

(7).Food Industry

-Bakery chiller; -Beverage chiller;-Fish Hatchery chiller-Food process cooling chiller -Hydrocooler chiller; -Ice cream chiller; -Yogurt chiller.

(8).Heavy Industrial

-Anodizing chiller;-Biodiesel chiller;-Biogas chiller;-Die Casting chiller;-HAVC Chiller;-Hydraulic chiller-Oil chiller

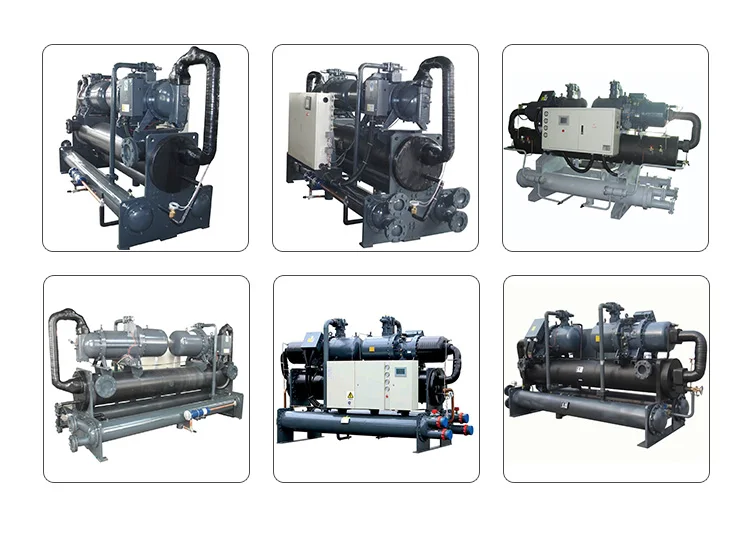

SIMILAR PRODUCTS

1. Air Cooled Scroll Water Chiller: Cooling capacity from 1 Ton to 50 Ton, adopt scroll compressor, use one compressor, two compressor system, 3 compressor system, or 4 compressor system, if you need smaller chiller can choose it.

2.Air cooled Screw Water Chiller: Cooling capacity from 20 Ton to 160 Ton, adopt SCREW compressor, use one compressor, two compressor system, if you are no convenient to install the cooling tower, can choose this chiller type.

3. Water cooled scroll water chiller: Cooling capacity from 1 Ton to 80 Ton, adopt scroll compressor, use one compressor, two compressor system, 3 compressor system, or 4 compressor system, if you need smaller chiller and convenient to install cooling tower can choose it.

FAQ

You may have some questions when use the water chiller in your plastic equipment? here is some questions from our customer usually ask, hope can help you.

Question 1. Chiller Capacity is effected by several factors:?

Reply: Incoming uncooled water temperature:

The warmer your water feed, the fewer yards you can cool with your chiller system.

The warmer your water feed, the fewer yards you can cool with your chiller system.

Question 2. Ambient Temperature?

Reply: High ambients lower the chiller’s capacity and make it less efficient. You should always size your chiller based on maximum summer high temperature. If it seldom reaches 100F, but usually stays around 80F, then you could be safe going with a 90degF factor.

Question 3. Why is the Evaporator Temperature Too Low in your Chiller?

Reply: When there is no refrigerant flow in the compressor, the evaporator temperature of the Plastic Chiller decreases.

Question 4. Added batch water amount?

Reply: The larger the volume of the water batch you mix to each concrete yard, the less yards worth of cooled batch water that the process can produce per day.

Question 5. What are the Safety Devices that are installed in Chillers?

Reply:

(1). Some safety devices for a Plastic Chiller are;

(2). Overload protection.

(3). Low water level alarm device.

(4). Wrong/reverse phase protection.

(5). High/low-pressure protection.

(6). Flows switch protection.

(7). Antifreeze protection alarm.

Company Profile

If you want know more about MGREENBELT Company

Established in 2003, MGREENBELT Specialized in manufacture chiller and chiller system including:

air chiller, water chiller, industrial chiller, oil chiller, glycol chiller, process chiller, screw chiller, mold temperature controller, cold room project for over 20 years experience.

MGREENBELT promise offers the best chiller&chiller system solution with competitive price to clients worldwide.

11605 Square meters factory area;

Within over 1000 chiller units produce every year, we thrive on providing high-quality water chiller;

20 Years Refrigeration experience, and 13 years industrial chiller manufacture experience.

MGREENBELT is one of the top brand with a goods reputation in China market since 2003.

We have a strong and united engineering team with rich work experience in industrial chiller filed;

Chillers manufactured from MGREENBELT are installed over 100 countries worldwide.

air chiller, water chiller, industrial chiller, oil chiller, glycol chiller, process chiller, screw chiller, mold temperature controller, cold room project for over 20 years experience.

MGREENBELT promise offers the best chiller&chiller system solution with competitive price to clients worldwide.

11605 Square meters factory area;

Within over 1000 chiller units produce every year, we thrive on providing high-quality water chiller;

20 Years Refrigeration experience, and 13 years industrial chiller manufacture experience.

MGREENBELT is one of the top brand with a goods reputation in China market since 2003.

We have a strong and united engineering team with rich work experience in industrial chiller filed;

Chillers manufactured from MGREENBELT are installed over 100 countries worldwide.

How to get a water chiller proposal and price?

1. You can click " Chat Now" Talk with our sale directly, we will reply you in immediately.

2. You can click " Contact" send inquiry to us, we will reply you within 1 hour.

3. You can send us message by whatsapp: +86-18615626360, or email by grace(at)mgreenbelt.com , we can reply you in immediately.

Похожие товары

Автоматическая духовка из нержавеющей стали для пищевых продуктов, оборудование для курения рыбы, коммерческая машина для курения мяса

2 600,00 $ - 2 850,00 $

Тактический Брелок большого размера для повседневного использования, подвесная Пряжка, уличный с бесплатным кольцом для ключей, портативный карманный зажим для брюк из нержавеющей стали

0,55 $ - 0,64 $

3-фазный инвертор ATV310 Schneider ATV310HU75N4E

Keyson OEM производитель алюминиевых инструментов, косметическая коробка

Материнская плата V230IC REV 4,0 для ASUS V230IC универсальная материнская плата с независимой графикой DDR4 100% ТЕСТ ОК отправка

CG автозапчасти Toyota Hilux хорошего качества 5TH переключения передач коробка части R507-17-308 53T/13T для Мазда Форд

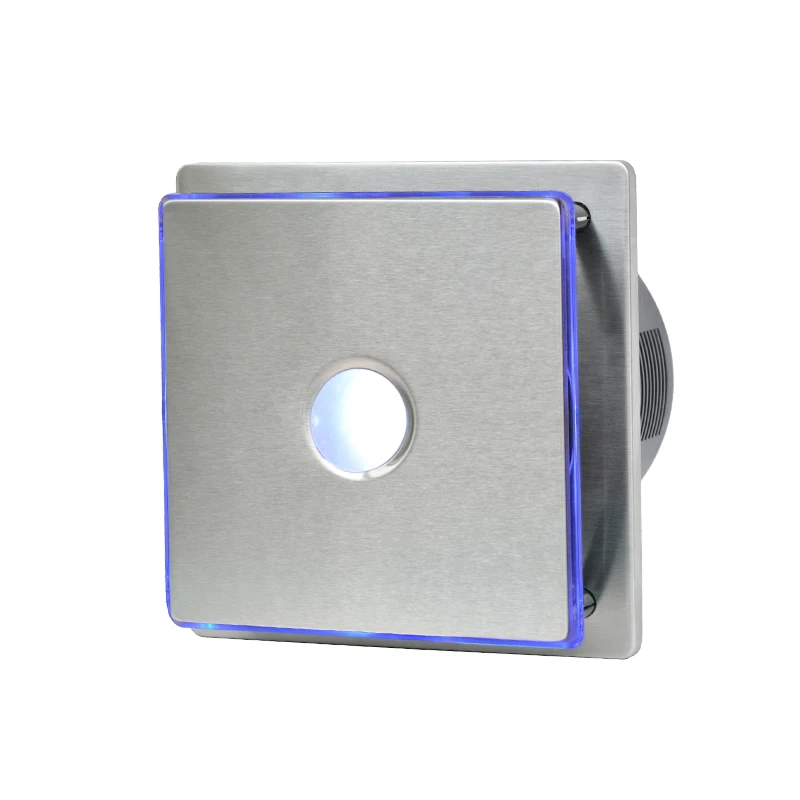

Вытяжной вентилятор для ванной со светодиодной подсветкой, 280 м3/ч

11,80 $ - 13,70 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Умный цифровой электронный ручной инфракрасный лазерный термометр для ветеринарного и медицинского мониторинга человека

5-10 $

Цифровой инфракрасный лазерный термометр для взрослых

5,90-6,70 $

Командная версия 24-скоростной ультралегкий карбоновый шоссейный велосипед Гоночная рама и комплект колес

Четырехцилиндровый двигатель CA6110/125G5 части клапана 1007011-A013-0000 1007016-A013-0000

0,50 $

55203781 46740344 55181201 55266538 зубчатый шкив коленчатого вала для FIAT 500 BRAVA BRAVO DOBLO PANDA PUNT0

3-3,70 $

Оптовая продажа 100% Рафинированное Масло из семян подсолнечника малазия масло для приготовления пищи

GY031 металлическая рамка пользовательских игровых сидений Sim гоночные игровые сиденья симулятор вождения кабины для Xbox 360 Logitech G25 G27 G29 G920

88-143 $

Роскошные пользовательские островные стулья современные кухонные с выдвижными ящиками и раковиной кухонный шкаф U-образной формы из нержавеющей стали

160-180 $