Polycrystalline Diamond PDC Cutter Inserts With Step for Marble Quarry

- Категория: >>>

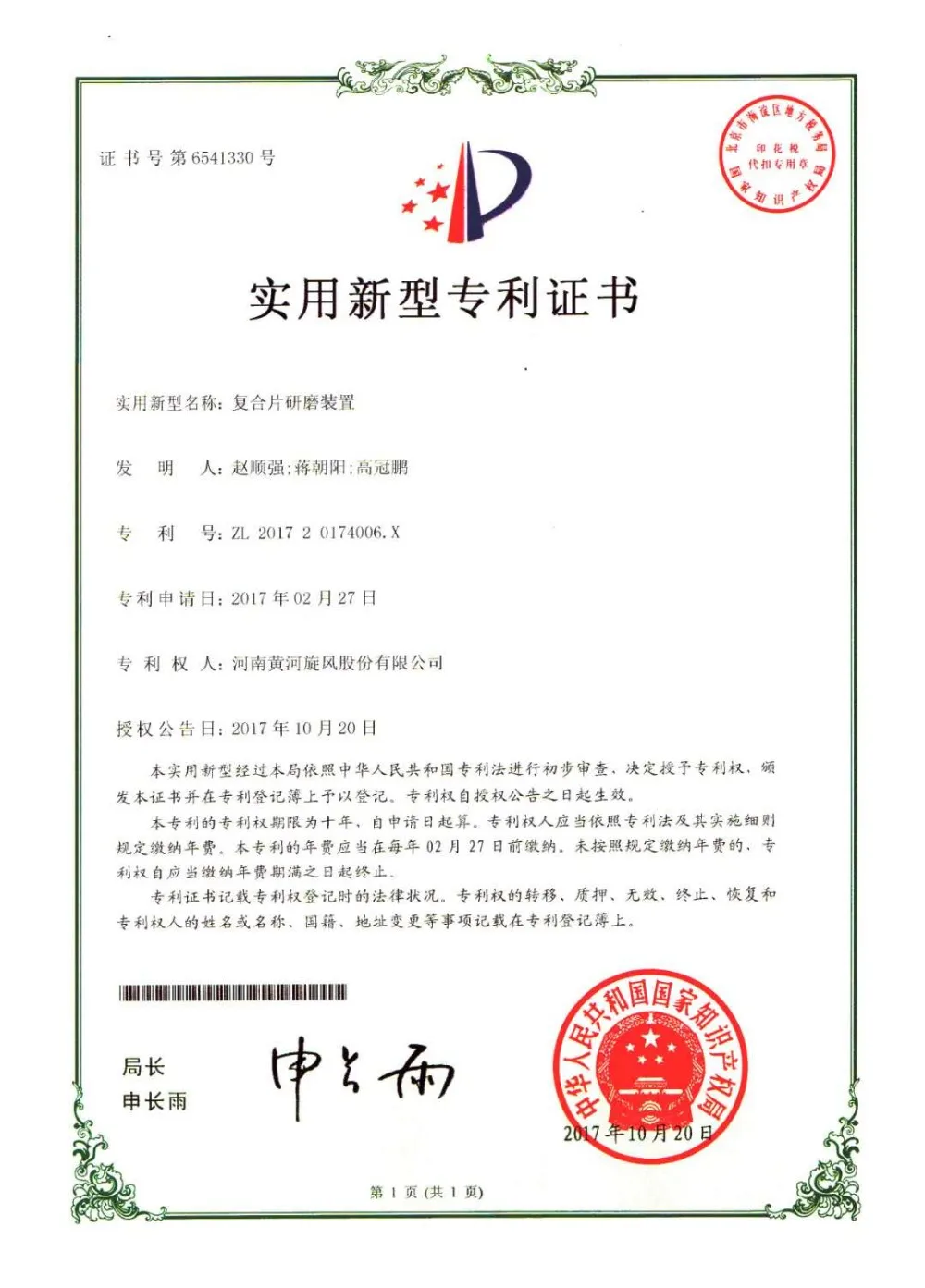

- Поставщик: Henan Huanghe Whirlwind Co. Ltd.Henan Ltd.

Сохранить в закладки 1600449979962:

Описание и отзывы

Характеристики

Product Application

Introduction of PDC

PDC is sintered of diamond micro-powder and tungsten carbide substrate under high temperature and pressure. It has great wear resistance like diamond, as well as the high impact resistance like tungsten carbide, what’s made it as the best drill bits' insert. Reinforced PDC has higher dense diamond powder, clawing tungsten carbide substrate made the two layers solid as a whole one.

Application

With high hardness, abrasion resistance and impact resistance, they are widely used for oil/gas drill bits, rock drill and coal mining drill bits, and also can be used for diamond tools for cutting, grinding, polishing.

Advantages

1.Optimized interface between diamond and tungsten carbide layers for excellent binding.

2.Penetration rate is improved by using high quality diamond powder which is self-sharpening.

3. Cutters can drill a precise round hole and reduce bit whirl as its force balanced design.

4. Gauge pads use tungsten carbide inserts for maximum wear resistance.

5. The diamond layer with thickness over 1 mm increases abrsion resistence of PDC cutter.

6.Good thermal stability.

Material: | PCD/diamond + tungsten carbide case | ||||

Application | Oil Drilling, Marble Quarry Drilling | ||||

Size | 1308/1313/1613/1913/1916 | ||||

About Us

Henan Huanghe Whirlwind Co.,Ltd is the professional superhard materials and tools manufacturer in China, based in Changge city, which is the superhard materials industry center, with more than 40 years of experience in development- research.

we own the high technique for PDC tools welding and our engineers keep long years with drilling field experiences, we know how to choose right PDC cutters to make qualified tools to maximum increasing the performance.

Our Main products: PDC cutter, TSP cutter, PDC tools.

Brand: HUANGHE WHIRLWIND

Original: China

Usage:

1) For oil drilling

2) For gas drilling

3) For mining bits

4) For coal drilling

5) For well drilling.

How PDC cutters are made

Polycrystalline Diamond Compacts PDC cutters are made by sintering micron sized diamond particles onto a tungsten carbide substrate. Sintering is carried out at ultra-high pressure and at temperatures in the range of 1350 – 1500 degrees. All our PDC cutters undergo rigorous 100% inspection that includes advanced micro crack detection analysis and ultrasound check.

Dimensions

1) Laser cutting machining precision:±0.05mm

Main Features

1) With feature of high working efficiency, smooth surface

2) Advanced technics and strict process control

3) Long lifespan and stable performance

4) Competitive price and superior quality

Packaging | ||

Size | 150mm(L) *80mm(W) * 16mm(D) | |

Weight | 0.02kg/pc | |

Packaging Details | The normal package is plastic box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to your require | |

Packaging | ||

Size | 100mm(L) * 80mm (W) * 16mm (D) | |

Weight | 0.02kg/pc | |

Packaging Details | The normal package is plastic box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. | |

Answer:Until now, we have already sold a large quantity of PDC cutters to Marble Quarries, including UK, Turkey, Portugal,Palestine,Italy and etc.

(2)What sizes PDC cutters are hot selling?

Answer: PDC cutter 1304,1308,1313,1613,1616,1913,1916,1919,1925 and other sizes.

(3)We are interested in your PDC cutters,we have some questions.How can I get your offer?

Answer:Kindly send us E-mail or call us,we will try all best to support you and give you good price.

Похожие товары

Wedding Royal Gifts Goblet Set of 2 with Gift

Мини-автоматический пресс для холодного отжима масла дома и

Атласная этикетка для ухода за кожей с инструкциями по стирке печати штрих-кодов 25*200 этикетки на заказ шапка

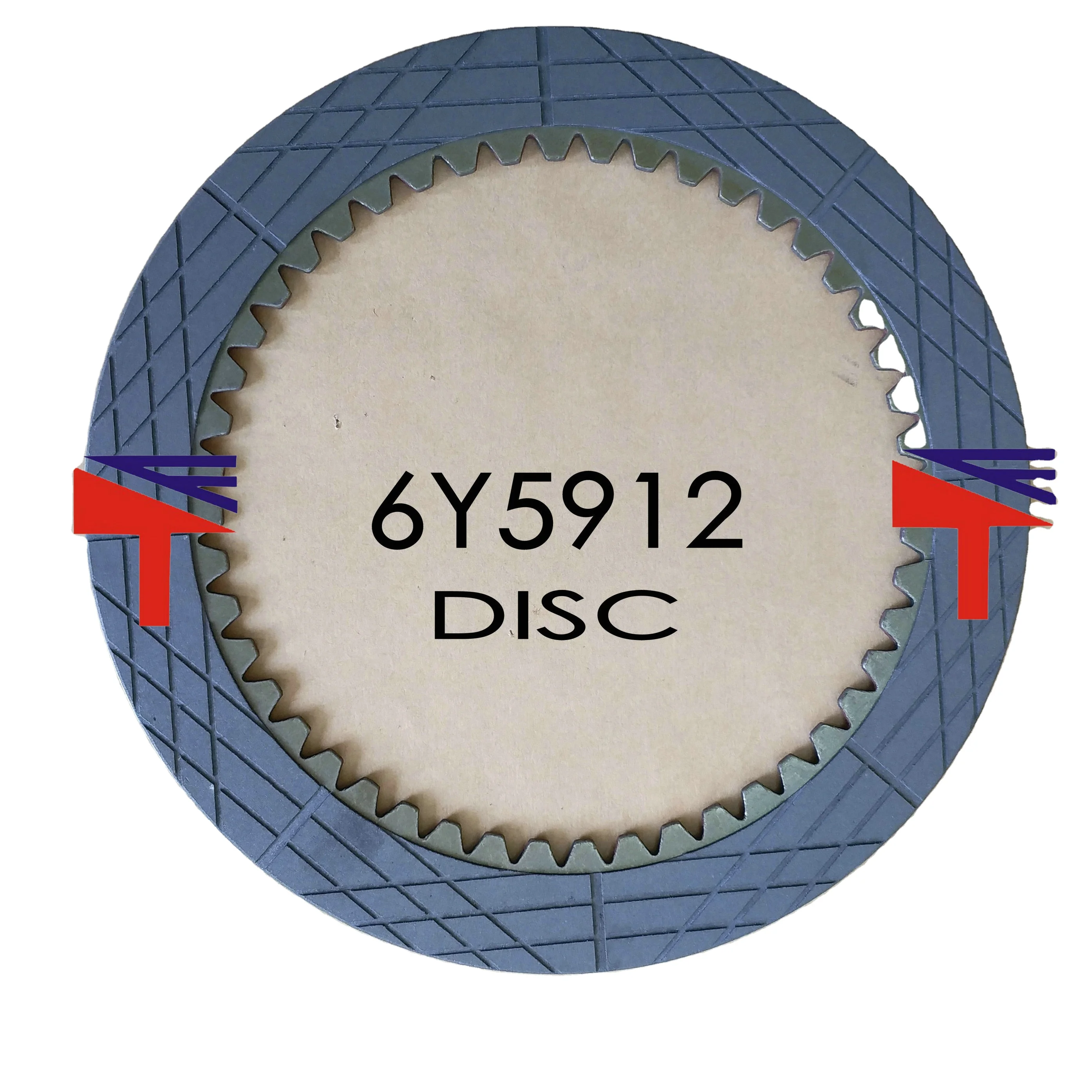

Диск трансмиссии 6Y5912 для колесного погрузчика 966F 966D 966G 966H запасные части 6Y2082

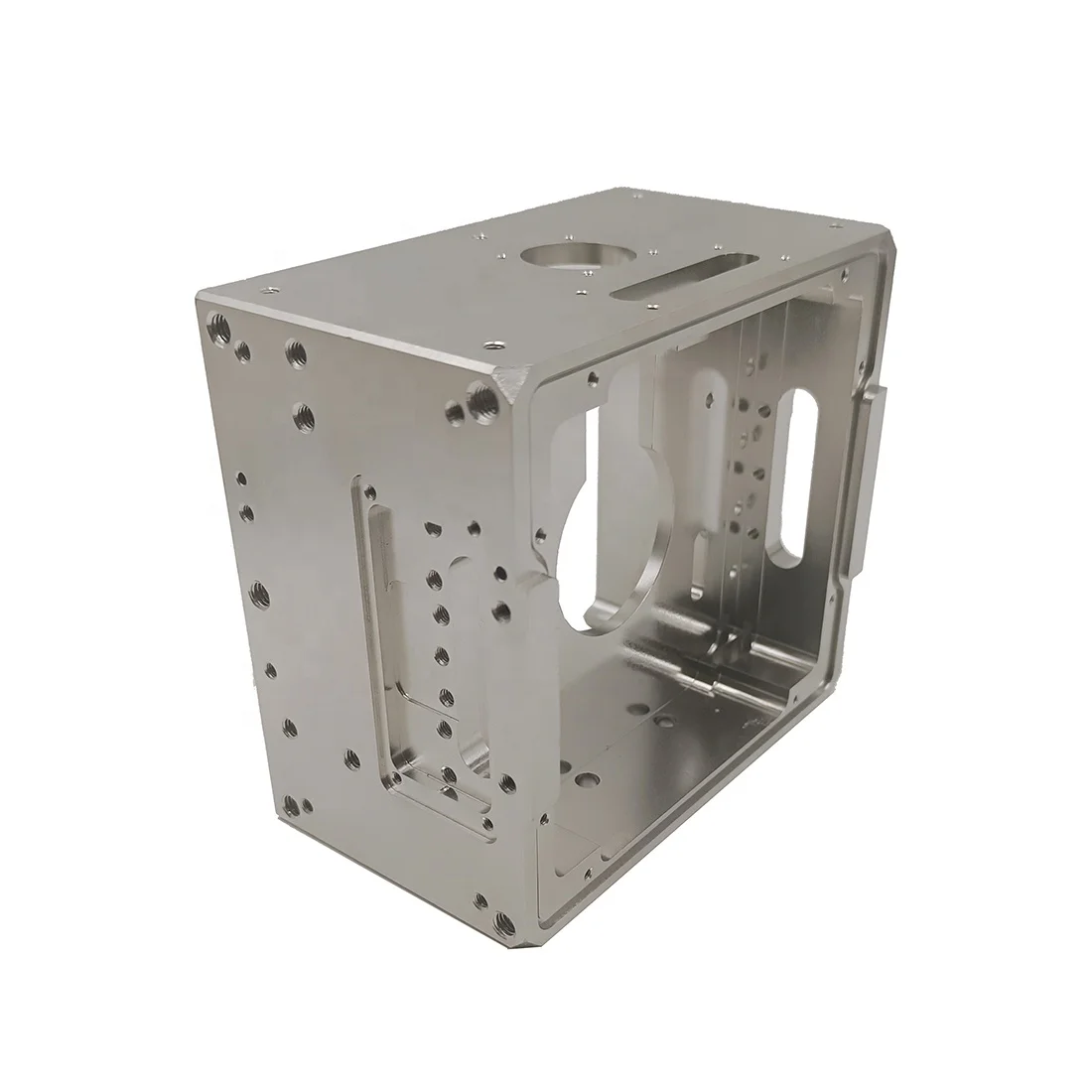

Изготовленные на заказ высокоточные Услуги обработки с ЧПУ из Нержавеющей Стали пескоструйная обработка анодированные модульные основные

Ветеринарные повязки эластичные для домашних

980nm стоматологический лазер для лечения ENT soft машина резки

Новые поступления

Новинки товаров от производителей по оптовым ценам