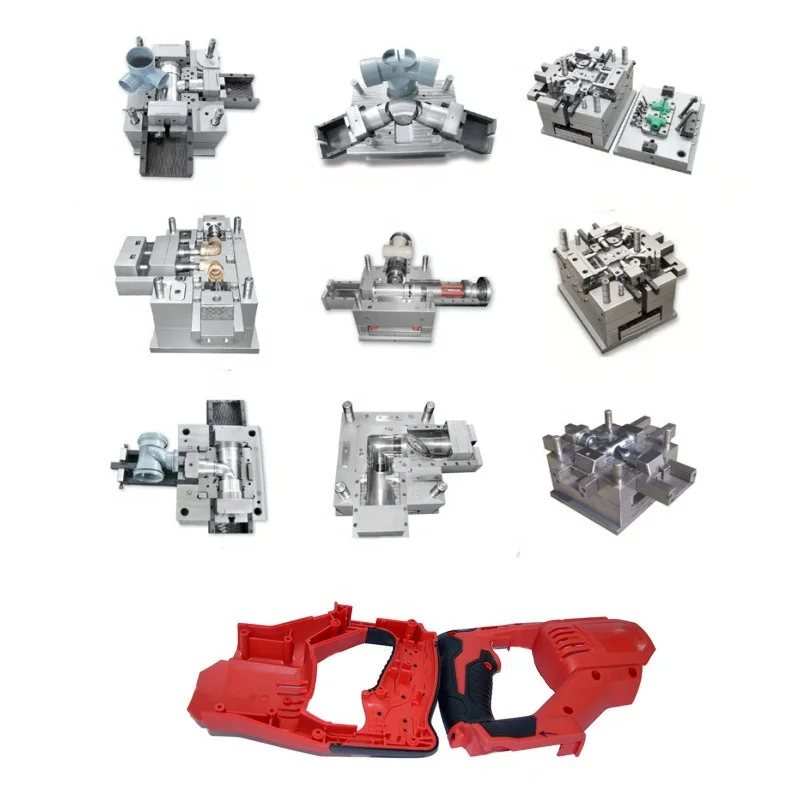

OEM изготовленная на заказ форма для автомобиля транспортного средства пластиковая Автомобильная дверь инъекции формовочная фар и литья

- Категория: >>>

- Поставщик: Shanghai Yuanhai Plastic Mould Co. Ltd.Shanghai Ltd.

Сохранить в закладки 1600450579757:

Описание и отзывы

Характеристики

OEM Custom Mould Maker Auto Vehicle Plastic Car Door Part Injections Molding Mould For Headlight And Moulding

With 30 more year's experience in injection mold & plastic mass production, now Shanghai Yuanhai is supplying plastic parts in Chery China and Romania, Russian, India, Masterfood in Australia, Lipton in UK, Yamaha & Fujitsu in Japan, Also we are cooperated with Simens in Germany, Samsung in Korea.

CUSTOM Mould. ANY YOUR design ACCEPTED.

TECHNICAL SPECIFICATIONS | |||

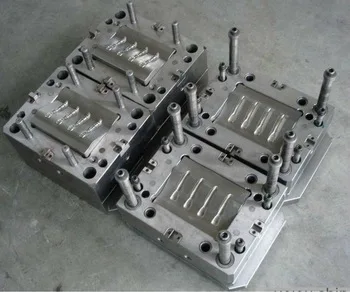

| Type Of Mould | Injection Mould | Small, Medium, Large Mold | |

| Mold Material | S136, P20, 718H , 2738 , NAK80 ,1.2311 Etc | ||

| Nr of Cavities | 1+1,1+2+1,2+2,4+4, Single Or Mutilcativies | ||

| Cycle Time | 10-30seconds | ||

| Injection Machine Weight | 90-1000ton | ||

| Life Span Of Mold | 300k-1000k | ||

| Shrinkage | According To Material | ||

| Product Material | PE,PP,HDPE,PPR,PVC,PP,PS,PET,ABS,PC,Etc | ||

| Injection Type | Hot Runner/Cold Runner | Hot Sprue, Sequential Injection/QTY Of Drops | |

| Gate Point | Edge gate, Pin point gate, Sub gates, Fan gate, Bayer | ||

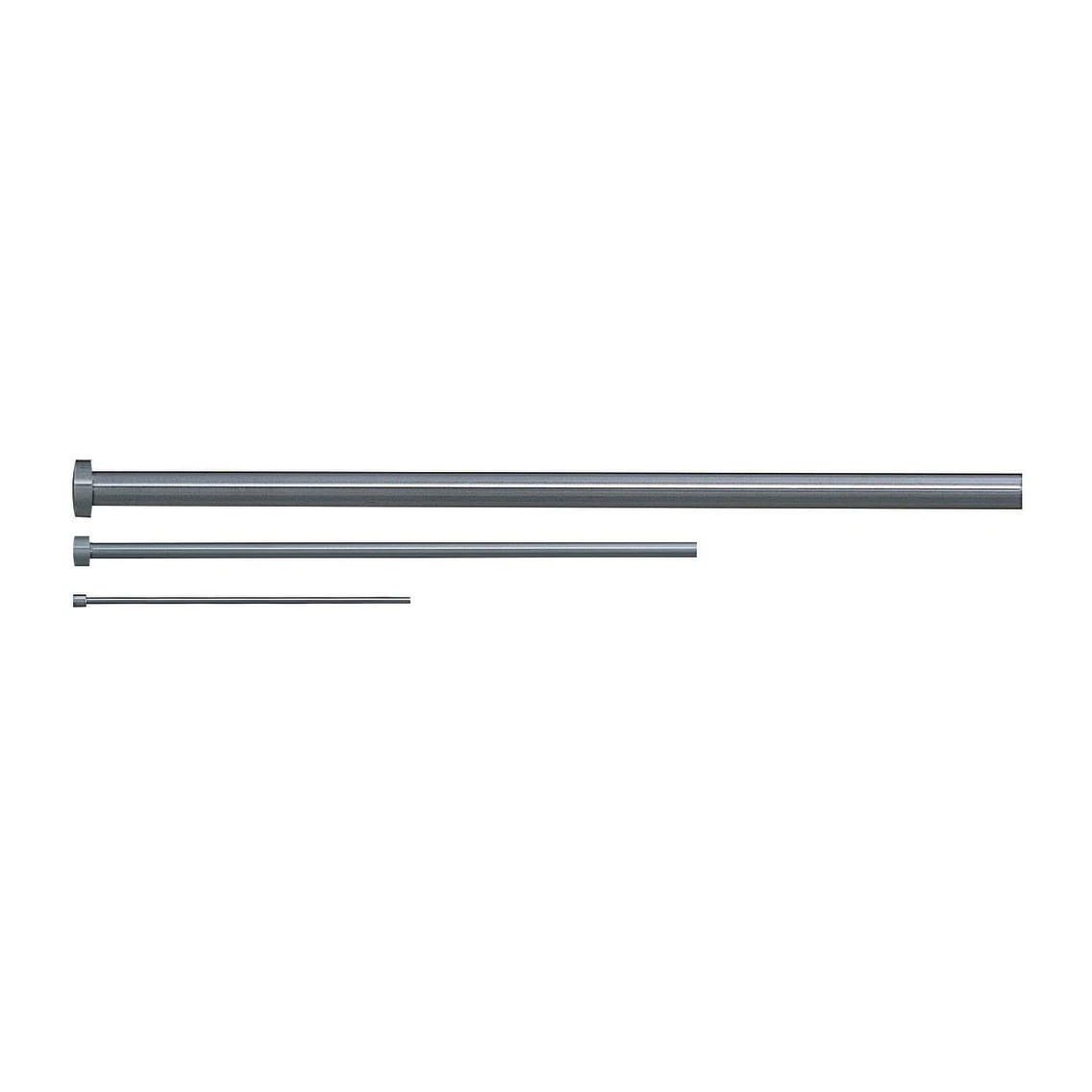

| Ejection | Round Ejector Pin | ||

| Slider | Outer, Inner Slider, Lifter | ||

| Surface Finish | Tech Polish, High Gloss, Texture, VDI 3400 | ||

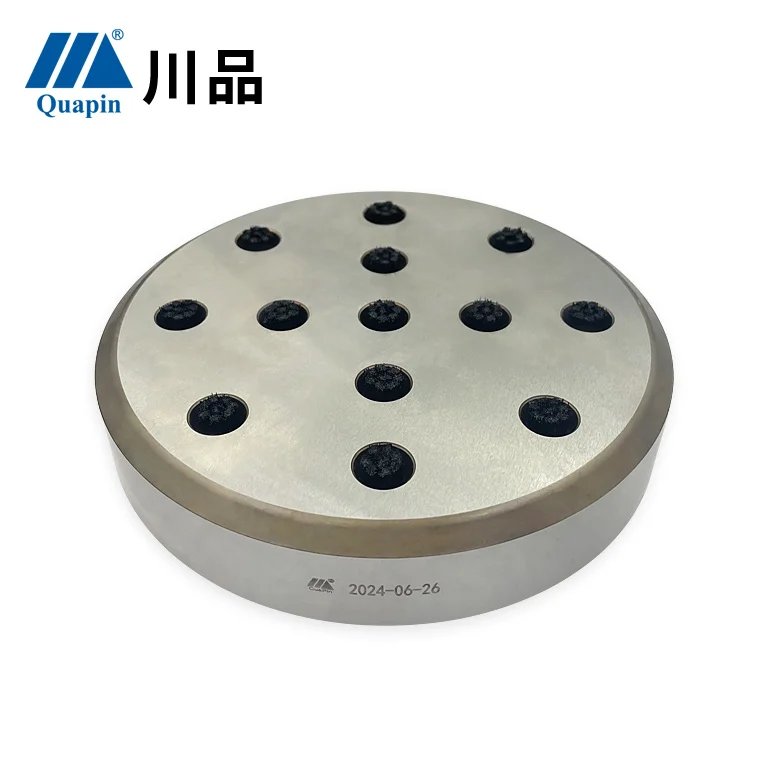

| Mould Hot Treatment | Tempering , Quending , Nitriding | ||

| Main Processing Equipment | Sodick, Seiki, CNC , High Speed Carve , EDM ,Wire Cut , Drill | ||

We can DESIGN for you.

make a mould and sample. also provide Mass Production for you.

Our Factory Equipment

Mold-made Whole Process

Our customers postive Feedback

SERVICES

OUR with confidence!!!

This is a

SELF-OWNED BRAND

offering this product with FREE Technical Support for mould

We make every efforts to let our customer feel 100% satisfaction,

and maintain a good and long term relationship with them.

FAQ About Plastic Mould Manufacturing

Q1: What kind of molds do you make? Plastic injection mold, Compression mold or something else?

A1: We are mainly making plastic mold injection and rubber compression mold.

Sometimes we also make die casting molds according to our customer’s requirements.

Q2: Can you make the texture / text / heat-treatment /nitriding for the inejction mold plastic?

A2: Yes, As plastic mold fatory, we have long-term cooperated subsidiary factories that do those processes.

They are professional and well reputed in our local market.

Q3: How long is the lead-time for a plastic injection mold?

A3: It all depends on the mold’s size and complexity.Normally, the lead time is 25—45days.

If the Plastic Mouldings are very simple and not big size, we can work out within 20 days.

Q4: Could you mass produce the plastic products?

A4: Yes, we have a mass production workshop, production capacity in the 10000 to 20000PCS/days.

Похожие товары

Поликристаллические алмазные штампы для рисования по индивидуальному размеру

Выталкивающая втулка выталкивателя

Индивидуальные пластиковые литьевые формы для литья пластмасс

OEM изготовленная на заказ пластиковая литьевая часть PC PA ABS PP PVC пластиковые изделия

Производитель OEM ODM изготовленный на заказ пресс-форма для литья пластмасс под давлением и литье пластиковых деталей

Murata Wiedemann tooling C3000 аксессуары для станков G/J

Производитель OEM пресс-формы для литья под давлением

Новые поступления

Новинки товаров от производителей по оптовым ценам