Устранитель тумана типа лопасти из нержавеющей стали с подушкой 170 мм

- Категория: >>>

- Поставщик: Anping County Hualai Metal Wire Mesh Co. Ltd.Anping Ltd.

Сохранить в закладки 1600451274984:

Описание и отзывы

Характеристики

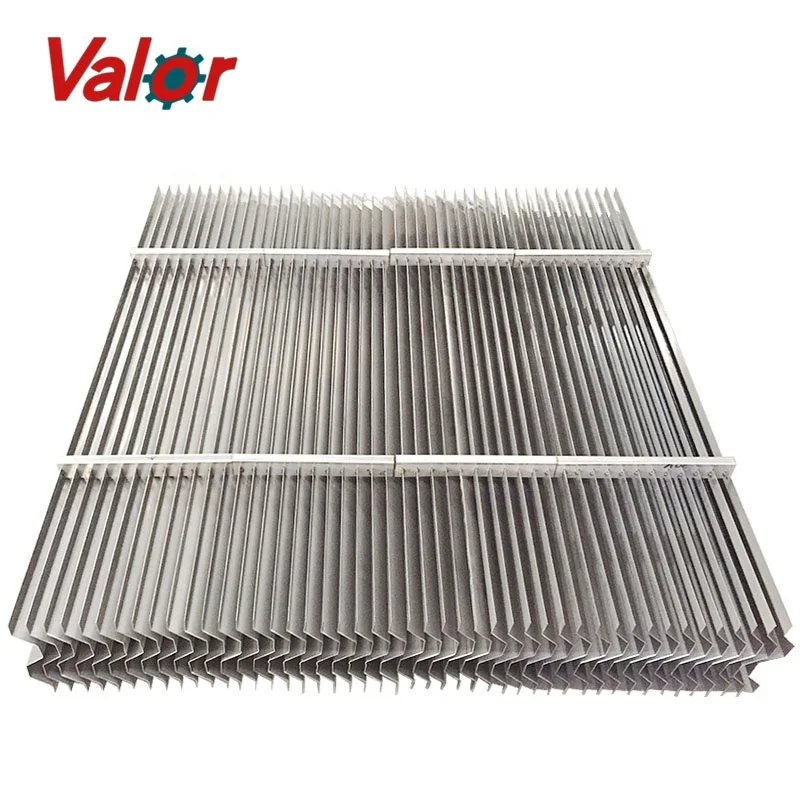

SS316L win vane type mist eliminator style V-C and V-CA with 170mm pad thickness,pressure drop <30 Vane mist eliminator

Anping Hualai Metal Wire Mesh Co., Ltd. is a 10 years factory producing vane mist eliminators, knitted wire mesh and wire mesh demisters. For now, we can produce three kinds of vane mist eliminators as shown below.

No. | vane shape | Material | Hook (yes/no) | Vane Height | Total Height with frame |

1 | Streamline line type | PP | yes | 170mm | 200mm |

2 | PP | yes | 235mm | 250mm | |

3 | poly-line type | PP | no | 170mm | 200mm |

4 | PP | no | 235mm | 250mm | |

5 | 316L | no | 170mm | 200mm | |

6 | 316L | no | 235mm | 250mm |

Vane Type Mist Eliminator

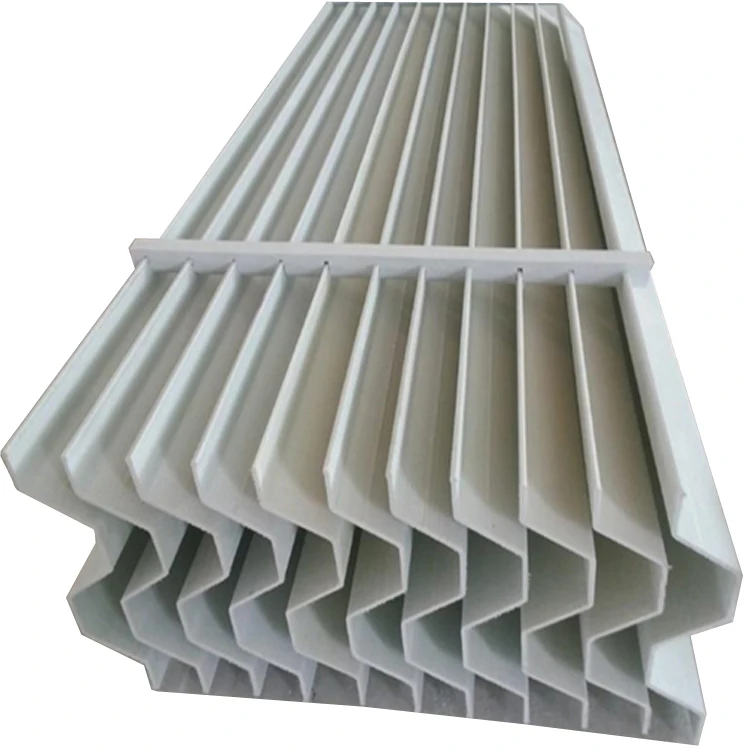

The vane types are the Chevron type of mist eliminators which consist of a set of specially designed vanes with a well defined geometry, with closely spaced corrugated plates. They are very usual and useful internals for liquid separation from gas. These types according to design and shape can remove the droplets more than 8 microns.

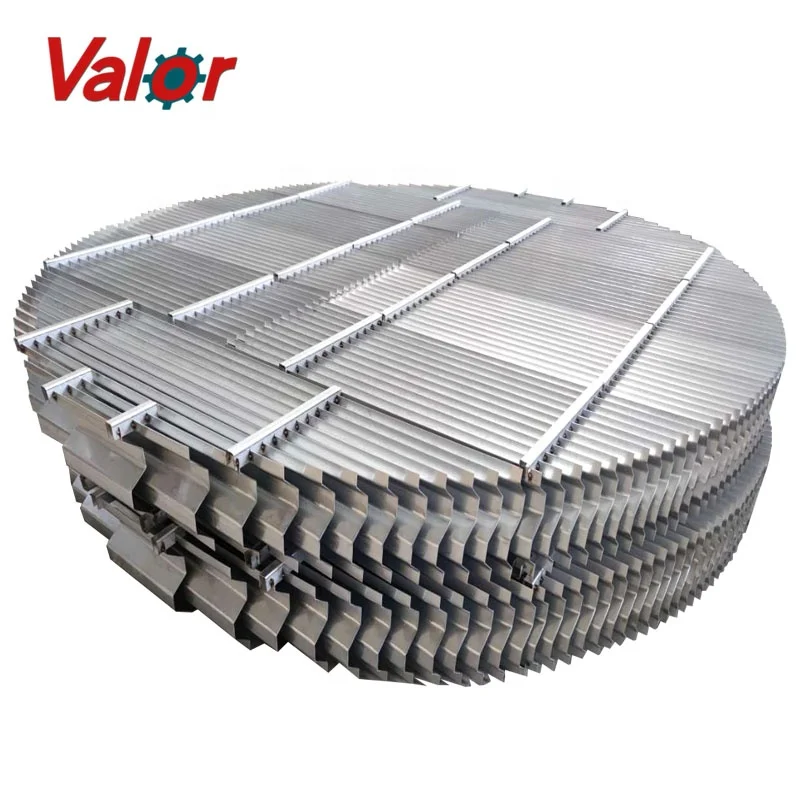

According to the passes. The vane demister pad has different passes, commonly, it can be divided into two passes and three passes. The number of passes corresponding to the number of times the gas flow change direction. More the passes, better the separating efficiency. Additional, the vane demister pad can be divided into stream line type and broken line type.

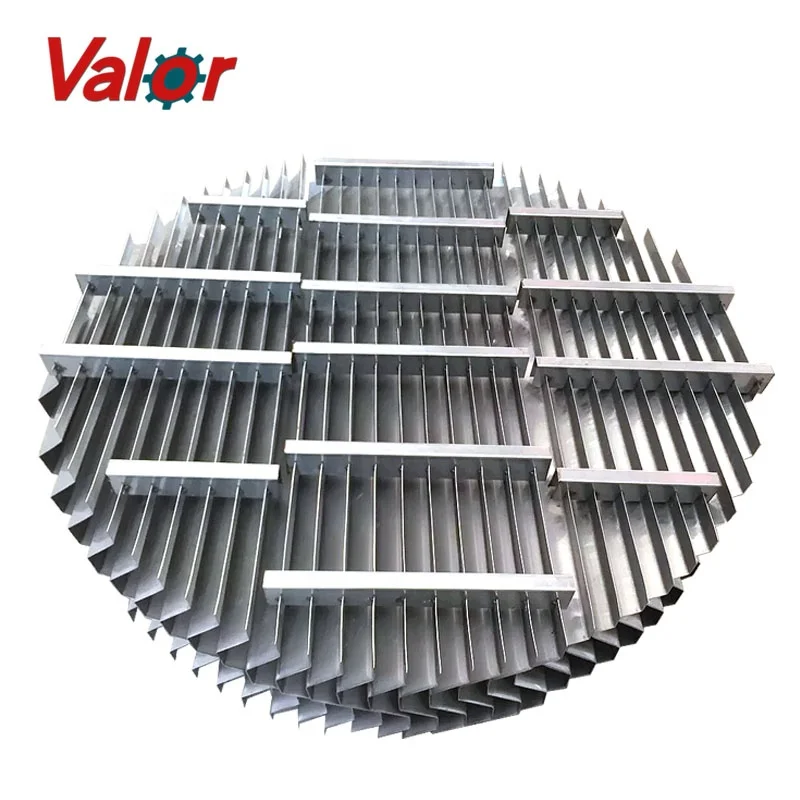

According to the shape. The vane demister pad can be made into different shapes, for example the round shape and rectangular shape. Additional, the vane demister pad can be integrated, it can also be divided into several parts for easy transporting and installing.

Specifications of vane demister pad

- Material: metal or plastic.

- Plate spacing: 1/2", 3/4", 3/8", 1", 1-1/2", 2" and others.

- Blade height: 5" or 8".

- Profile depth: 1/2" - 3/8".

- Blade thickness: 0.46 mm.

Features of vane demister pad

- High capacity. It can improve 30% to 100% more capacity than the wire mesh demister pad.

- High filtering and separating efficiency.

- Lower pressure drop.

- Durable and long service life.

- High vapor capacity.

- Resistance to fouling.

- High tensile strength.

- Custom-made design available.

Applications of vane demister pad

Vane demister pad is widely used in various applications to separate liquid droplets from gas streams, in all applications where a contact between liquid and flowing gas, the vane demister pad can supply a good performance. Additional, tiny mist droplets can be carried away with the gas.

It is widely used in the foaming system and high liquid viscosity system in refineries, chemicals, petrochemicals, pharmaceuticals, dyes and intermediates, aromatics and other process industries.

Hualai has produced a range of mist eliminators for critical applications in the oil and gas sector, Standard Material of vane type mist eliminator is polypropylene & stainless steel.

When to use vane type mist eliminator instead of mesh pad?

Larger droplets;

High Gas Velocity;

Low Pressure Drop;

High Liquid Load;

Extremely Viscous Liquid;

Accumulated Residues;

Clogging Particulates;

Severe Corrosion;

Surge Buffeting;

Foam Problems

Removal of very small droplets can be achieved using a two stage mist eliminator by fitting a mesh pad to the upstream face of the unit to coalesce droplets as small as 4 to 5 microns into droplets in the size range which are easily removed by the vane separator.

Contact now for more details!

Похожие товары

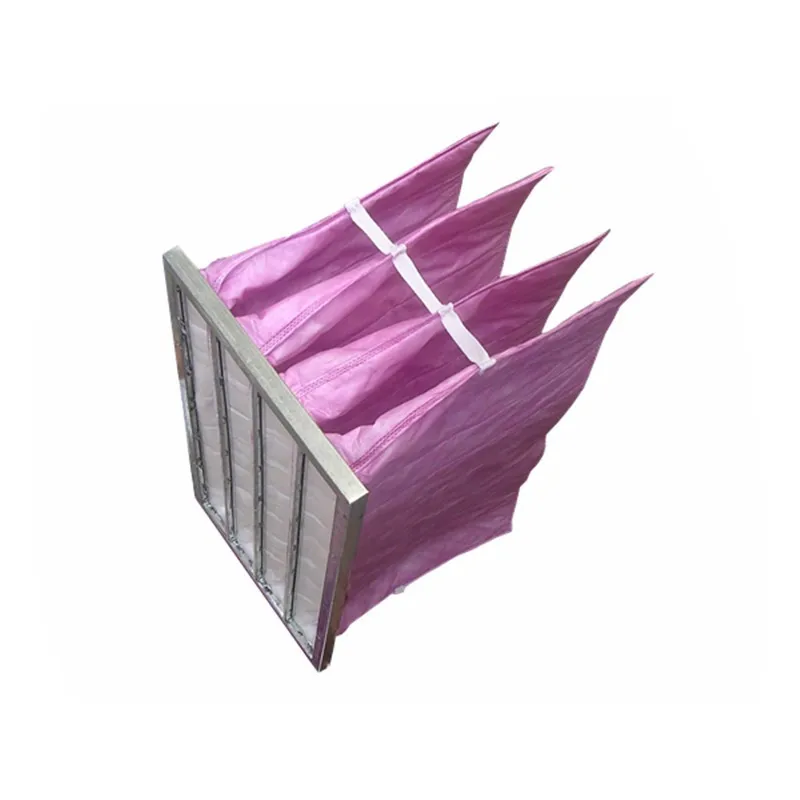

Настраиваемая Новая краска для выпечки туман войлок распылитель комнаты освещение окисление аэрозольный фильтр из хлопка воздушного фильтра хлопок

APFG4-310 G4 замена фильтра Hepa воздушный фильтр для pluggit Avent P310 вентиляции

Воздушный фильтр сапуна SA12519

Фильтр для внешней строительной техники CMC5083 P500139 740A74 740A76 DA5205 WCA3480

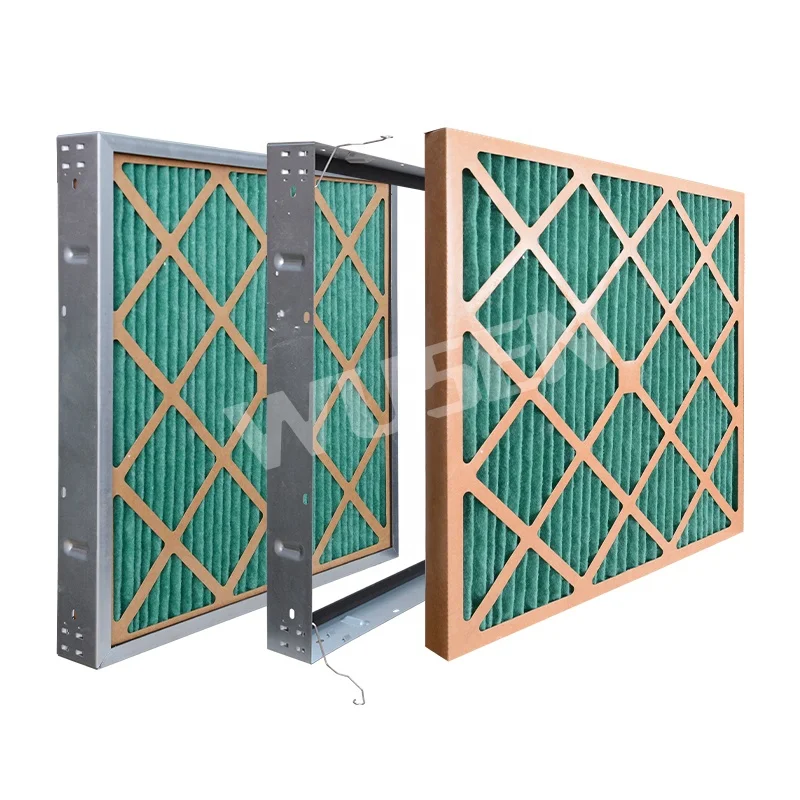

Фильтрация воздуха для аквакультурных ферм плиссированный синтетический волоконный сельскохозяйственный воздушный фильтр

Новые продукты для LG запчасти Воздухоочистители замена фильтр подходит AS111VBS/AS122VDS

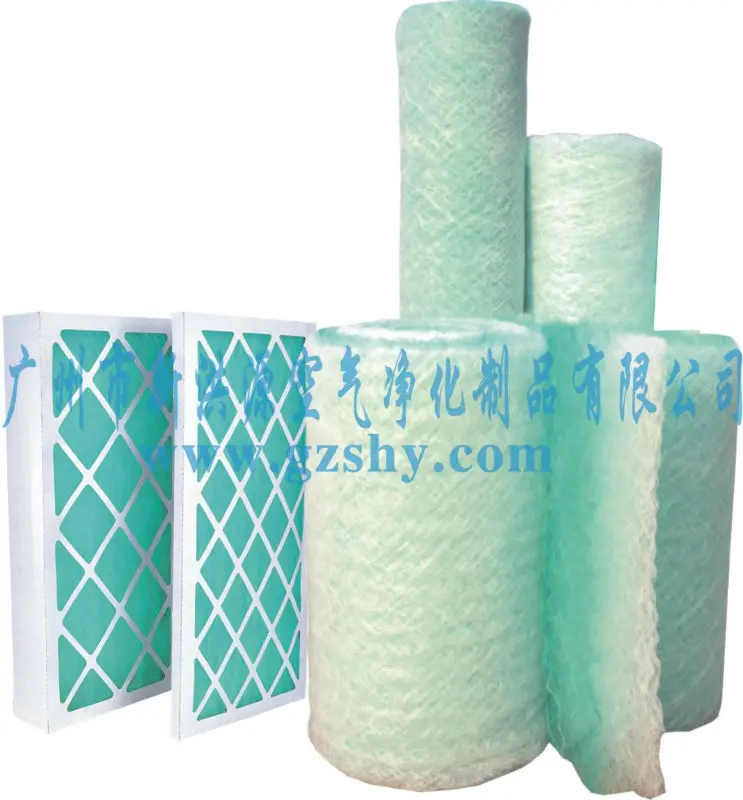

Европейский стандарт EN 779 G4 фильтр предварительной очистки панели

Новые поступления

Новинки товаров от производителей по оптовым ценам