ПВХ покрытием гипсокартон потолочная производственная линия. Автоматическая машина для ламинирования

- Категория: >>>

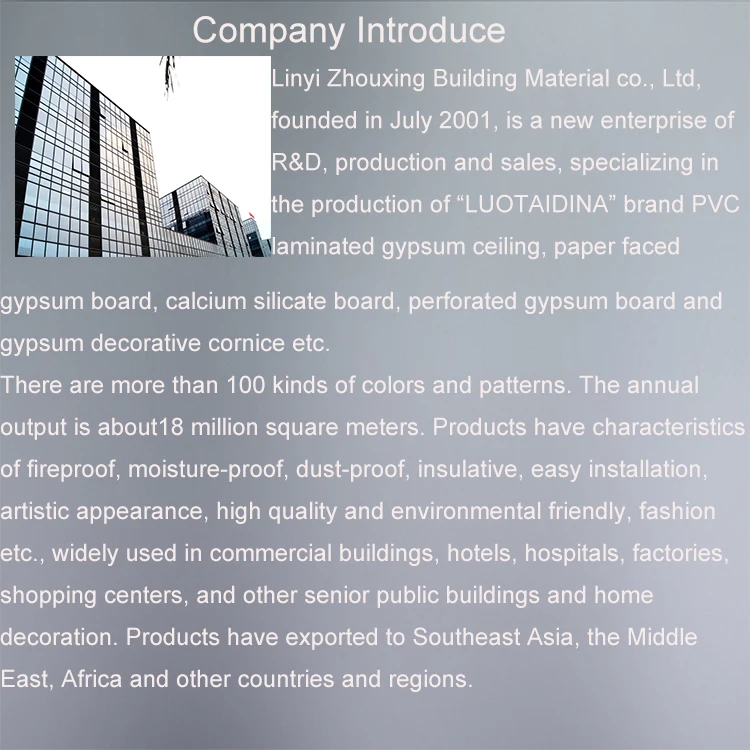

- Поставщик: Linyi Zhouxing Building Materials Co. Ltd.

Сохранить в закладки 1600460700284:

Описание и отзывы

Характеристики

Automatic PVC Gypsum ceiling tiles Making Machine

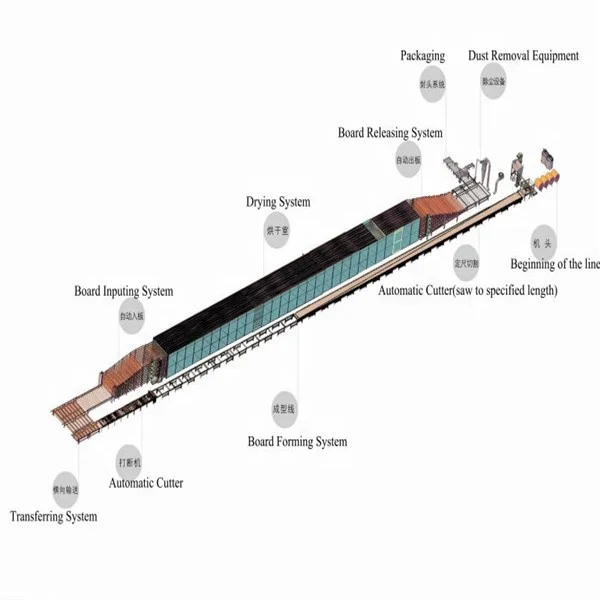

1250 Ⅰ type gypsum ceiling production line is a new generation of ceiling production equipment. Adopting PLC intelligent controlling system, by chain and belt transmission, double-sided coating, cutting, sealing, packing and stacking could be done aromatically . It has advanced technology, compact structure, reliable operation, nice shape. The finished product is interior decoration materials with large demand currently. Gypsum ceiling tiles are fireproof, waterproof, light, soundproof and have various styles, concise appearance and convenient installation. it is suitable for density board, MDF, fire prevention board and gypsum board’s coating jobs and has gradually get market and customer acceptance.

Working process

Introduction of main equipment

Main technical parameters:

4.1 Dimension: 32.5M(length )X13.5M(width)X4.5M(height)

4.2 Maximum dimension of board: 2400mm*1250mm*15mm

4.3 Maximum finished product packing size:603mmX1210 mm

4.4 Transmission power: 29.55KW

Workers:

Working shift: 1

Working Time: 8hours/shift

System

| Personnel Allocation |

Forklift driver | 1 worker/shift

|

Operator | 7 workers/shift

|

Total |

8 workers |

1) Different automatic levels for your choice.

2) Adopting world famous brand Siemens PLC control system

3) High capacity of 4-8 million sqm per year.

4) Raw materials: Gypsum board, PVC film, Aluminum foil, glue

5) Effective laminating width: Max 1300mm

6) Sheet thickness: 5--30mm

7) Speed adjust way: frequency conversion synchronous speed regulating

8) Certification: ISO9001, SGS, CE, ROHS

Похожие товары

7 мм Grey потолочный волокнистый цементный Картон машина для производства целлюлозного цементного листа

Автоматическая машина для производства цементных листов из целлюлозы, силиката кальция, Потолочная Плитка, производственная линия, машина для производства Цементных плит

Автоматическая машина для производства цементных листов целлюлозы 25 мм линия по производству цементных плит

Хорошая высокопроизводительная линия по производству гипсокартона для продажи

2024 Высококачественная производственная линия гипсокартона высокой производительности для продажи

Легкая изоляционная стеновая машина SIP

Легкие композитные теплоизоляционные стеновые панели Eps бетонные стеновые панели Eps пенопластовые машины Eps сэндвич-панели

Новые поступления

Новинки товаров от производителей по оптовым ценам