HY J03 Тип 25 27L магнитное кольцо индуктивности булавки для рисования и режа формируя машину

- Категория: >>>

- Поставщик: Dongguan Huiyue Automation Equipment Technology Co. Ltd.

Сохранить в закладки 1600461438850:

Описание и отзывы

Характеристики

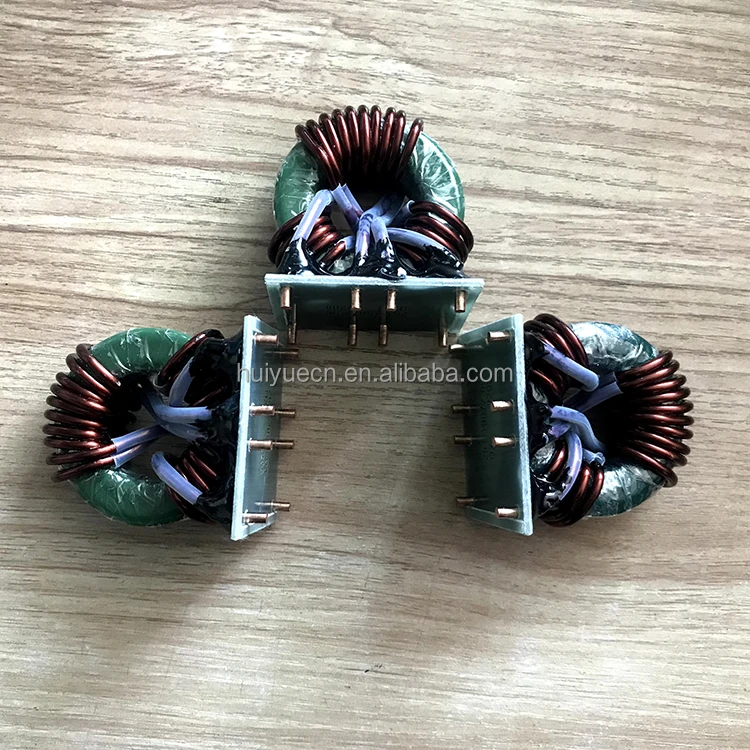

25-27L all-in-one machine for drawing, shearing and forming; it is a self-developed machine for drawing, shearing and forming of magnetic ring inductance pins; this model is specially designed for T6X3X3.T9X5X3, T10X6X5 and the like. Wire diameter 0.3MM-1.0MM comparison A model of the commonly used magnetic ring inductance design, this model provides the ability to complete the stretching, shearing and shaping work, and the whole process can be completed within 0.3 seconds. High processing efficiency, good product quality, and low labor cost toroidal inductance pin cutting and shaping equipment. Due to the stable equipment and wide adaptability, it is loved by the toroidal inductor processing industry.

Main features

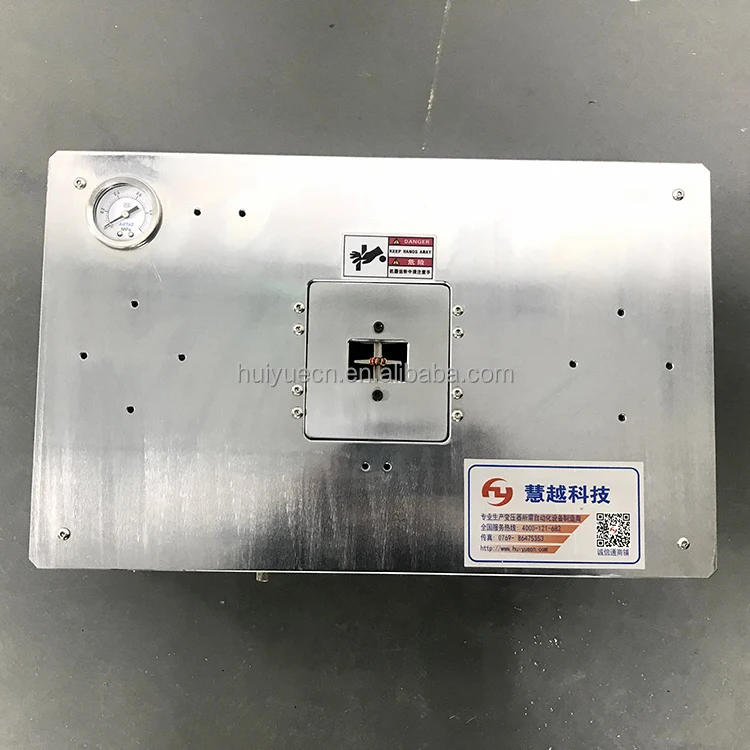

The whole is small and compact, the panel is made of ace steel, the surface is electroplated and hardened, and the design surface is flat; the ergonomic design is in line with the ergonomic design, and the operator will not feel tired for a long time; the aluminum alloy sandblasted and oxidized chassis makes the overall weight lighter and the appearance more beautiful;

The pay-off port adopts 4MM thick steel protective plate. Protect the machine's working cutter from hurting your hands. Safer operation;

The panel is embedded with a pressure dial, and the pulling force is intuitive;

The tension adjustment knob is designed behind the frame to adjust the tension for different types of magnetic rings and wire strength

Using high-quality double-axis cylinder, stable work, large cutting force and fast speed.

Wide compatibility, the small ring is directly formed, which can be used for shaping and pedicure of the upper bottom plate and the product after soldering. A direct replacement for the old forming shears.

Use ordinary 0.8mpa air compressor air source. 220V power input.

Installation Notes

1. The filter regulator is installed vertically, the left side is connected to the air compressor, the right side is connected to the machine, the pressure is 0.4-0.45MPA (the factory has been adjusted to not exceed 0.5MPA), otherwise the cutter will not cut or straighten the phenomenon;

2. Observe whether there is moisture in the jar every day, and push the drain thimble under the top of the jar to eject the water to prevent water from entering the solenoid valve and damaging the components.

Note: The voltage stabilizer filter cannot be reversed, it is fixed and cannot be adjusted, check the moisture every day

Function Description

1: Pressure display - display the current tension of the wire. The higher the value, the tighter the wire is pulled;

2: Capacity display - display the current output. (Only the aluminum alloy panel version has this function)

3: Tension adjustment - adjust the clamping strength of the product pins, (1 pressure gauge display), the higher the adjustment, the tighter the tension, the more beautiful the pin position, note: if it is adjusted too high, the pins will be broken; some products will also There is a phenomenon of poor pressure resistance; or some products with thick wires (above 0.8MM) will not cut the knife. Adjust the appropriate tension according to the actual situation of each different product.

4: Air source interface - connect to the pressure stabilizer filter attached to the machine, (the filter must be connected, otherwise the water entering the machine will damage the equipment in advance)

5: Household 220V power interface

6: Power switch - the equipment must be parked for a long time, and the power must be turned off to replace the fixture

7: Foot switch interface - connect to the included 2-pin foot switch.

8: Yield reset button (depending on the version, some are start buttons)

9: Speed adjustment, pressure compensation knob, the slower the speed, the greater the tension compensation, the more stable, on the contrary, the faster the speed, the smaller the tension. The factory has been adjusted to the most suitable state, and the wire diameter within 0.8 does not need to be adjusted.

Replace the jig

1: Turn off the power first. Loosen the bolts of the fixture cover, take out the fixture cover, and then install the whole set of fixtures (5 pieces + 1 fixture head) in sequence; be sure to turn off the power before operating

2: When installing the jig, first install the matching jig head under the chassis, and then install 5 pieces of jig in sequence. Cover the jig cover,

Note: After covering the jig cover, put on the jig cover screws, twist the screws in place by hand without tightening them, and then turn on the power switch. Step on the foot switch and then tighten the screw. Tightening too tight may cause the cover plate to deform and affect the jig not to work properly

3. Change the jig head: turn the device over and replace the bottom jig head;

1. Loosen half a turn of the fixing screw, rotate the fixing tablet, and use pliers to pull out the fixture head;

Note: The bolts of the fixing plate cannot be completely twisted, half a turn is enough, otherwise it is difficult to install them back

usual maintenance

The equipment must pay attention to the maintenance of oiling and lubricating the moving parts. Oil maintenance at least once a week. Open the jig cover.

Accessories: one filter regulator, one power cord, one foot switch, one 3MM hexagon wrench, one bottle of lubricating oil. Note: The air source filter regulator must be installed, and the installation distance is within 2 meters of the device. Install vertically facing the pressure gauge bottle facing down. The left side is connected to the air compressor, and the right side is connected to the equipment. The pressure is adjusted to about 0.4MPA, not more than 0.5MPA, and it has been adjusted at the factory).

Model : HY-J03 |

Magnetic ring type: outer diameter 6-25mm |

Max pitch: 15mm |

Maximum row spacing: 14mm |

Wire diameter range: 0.3-1.0 (mm) |

Average output value: 600-2000pcs/hour |

| Machine size: 420L * 260W * 123Hmm. |

Weight 15KG |

24 hour online technical support and 100% quality warranty for 12 months except consumable parts.

Our vision : created a century brand success for centuries

Our mission : to promote the progress and development of the most cost-effective automation technology

Our values : customer first, teamwork, loyalty, dedication, passion, dedication

Our business purpose : to satisfy customers, employees, businesses of both material and spiritual well-being

Our quality policy : quality is life, progress endless; service is fundamental, innovation to win

Our commitment : no excuses

Our two style : serious, fast

Our three thanksgiving : thanksgiving customers to create my performance,thanksgiving my career platform company, thanksgiving working with my colleagues

Dongguan Huiyue Automation Equipment Co., Ltd. FAQ:

Q: What is the power supply of the machine?

A: The standard power supply in china is 220v 50Hz. We also can customized accordingly.

Q: Our required parameter is not standard,can made to order?

A: Our machines can made to order according to customer’s requirement.

Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, etc

Q: What is the payment term?

A: T/T , L/C.

Q: What is the delivery time?

A: Normally the delivery time of the machine is 4-5 working days after receive payment.

Q: What is the warranty period of the machine?

A: The warranty period is one year.Lifetime Maintenance

Похожие товары

Маркеры с жидким мелом 8 мм магнитная белая доска пригодная для переработки/негибкая маркерная ручка

GAX-MF8 8 канальный аудио смеситель 16 Цифровые эффекты реверберации три полосным эквалайзером микшерный пульт с USB + 48В

Дозирующая крышка YORKER, красная крышка для склеивания и краски

Расческа зубная щетка зубная паста тапочки фабрика бар мыло упаковочная машина мини бар мыло машина

Сделано в Японии лучшее сцепление IQ880-N-BL, быстро сохнут, FOL13B на основе растворителя темно черый IQ880 красный чернильный картридж для ручной принтер

Дока дока для лесоматериалов Prima H20, стеновая опалубка для бетонного строительства, Европейская фанерная колонна

Высококачественные Нескользящие поручни из ПВХ для прихожей, поручни из нержавеющей стали для больницы

Новые поступления

Новинки товаров от производителей по оптовым ценам