Гибкий Магнитный цилиндрический ролик для роторной печатной машины

- Категория: >>>

- Поставщик: Jctprint Machinery Co. Ltd.

Сохранить в закладки 1600463067631:

Описание и отзывы

Характеристики

Flexible die cutting magnetic cylinder roller for rotary printing machine

1. Description of magnetic cylinder

Flexible magnetic cylinder also called flexible blades die cutter, flexible magnetic blades and rotary solid die.

Using mould steel, imported high viscosity adhesive and permanent magnetic block, after baking and shaping, the outer circle is finely ground and formed in one piece; its precise outer circle size, together with the flexible blade, can achieve up to 0.03mm die-cutting accuracy.

2. Application

The magnetic cylinders are applicable for all kinds of rotary press with rotary die cutting seat, including full rotation letterpress, full rotation flexographic press, full rotation combined press, batch-type letterpress. It is also used for other special processing equipments, such as commercial form machine, envelope machine, and specialist processing rotary die cutting machine etc. High-temperature magnetic rollers can be used for cold and hot hot stamping, leather embossing, etc.

3. Technical parameters

01.The usual gap of magnetic cylinders is 0.48mm, 0.58mm, 0.74mm.

Label die cutting gap: 0.48mm, electric die cutting gap: 0.58mm, Rfid chip cutting gap: 0.74mm.

02. Die cutting can be divided into full rotation die cutting and intermittent die cutting

03.The gear modulus: English system 1/8CP and Metric system M1 gear modulus and M2 modulus.

04. Die cutting mark is dividing in to light, standard, deep; the blade angle is single 30°,35°,40°; the angle of PE is usually between 25°~30°,the angle of paper is usually between 35°~ 40°.

Why choose us ?

01. Adopt set pillow shoulder, full vacuum heat treatment to hardness HRC 60-62 degrees, to ensure its superior wear resistance and long-term use stability.

02. The use of high quality NdFeB magnets and ferrite magnets ensures superb suction of the magnetic roller body, so that the knife plate will not be displaced on the roller surface. When die-cutting, the surface in the die-cutting seat will not move out of position due to friction with the material.

03. Adopt imported anti-static and high temperature resistant adhesive, through strict temperature control, so that it can strengthen the function of anti-ionization while curing, under high speed operation, no space electric field is generated, to make sure that the electronic die-cutting does not hit the transmission of semiconductors.

04. With five-level precision hardened gears, tooth surface quenching and fine grinding, good silent effect; can be the roll body pillow shoulder spacing accuracy in 1 micron, TIR within 2 microns.

And gears are also made according to the original design requirements of the machine, each equipped with precision processing and anti-rust treatment technology to ensure the precision of the gears and normal drive the roll body die-cutting work

05. We can also design positioning pins on the surface of the cylinder to prevent displacement of the flexible mold during use.

Production process

The magnetic cylinder is made of steel with a magnetic block set into a groove milled into it, and the high strength adhesive and permanent magnetic block are glued together and then completely cured or cured by heating,

followed by fine grinding of the outer circle. The roundness and finish of the surface of the roller body is achieved after fine grinding. The accuracy of the outer circle is ensured to be within 0 to 5 microns,

which is to ensure the accuracy and stability of the round die-cut stickers. Including pillow shoulder, roll body and both ends of the shaft. Pillow shoulder and roll body spacing precision control in 1 micron,

the same need to be equipped with high-quality magnetic blade to achieve efficient and accurate die-cutting effect.

Magnetic cylinder pictures

Packaging

The cylinder packaging by Wooden Box .

It will has the test report for each magnetic cylinder ,the test report will in Wooden box .

Shipping

The shipping will based on your requirements ,By Sea ,Air or International Express also are okay .

If you have forwarder in China ,you also can arrange the shipment by yourself .

1. When can I get the quotation?

We usually quoted within 24 hours after receiving your inquiry. If you are very urgent to get the price, please call us or tell us in your email, so that we can regard your inquiry priority.

2. How should I place the order?

Please show us your drawing, or let us know your request, and then we will provide you drawing for confirmation.

3. What’s your MOQ basis?

1 piece or 1 set, it depends on your actual requirement.

4. What about the lead time for production?

Usually around 25 days, but it also depends on the order quantity and the type of our products.

The flexo printing cylinder

Ceramic anilox roller

Похожие товары

A220062 коническая шестерня 14 т для Noritsu QSS 2301/2601/2701/2901/3001/3202/3300/3501/3701/3702 минилаборатория (2 шт./лот)

Noritsu minilab Frontier QSS-3001/3021/3300/2611/3501 часть минилаборатории A061850 A061850-01 губка поглощает водяной принтер

Noritsu minilab Новинка A040188 QSS-3001 передач/3021/2600/2611/3300/3501 запчасти

NORITSU MP1600 / QSS 2700 2701 2711 3001/3011 запасные части для минилаборатории #3 4 5 и 6

Ремонт источника питания Блок для Noritsu QSS 3001 3300 3301

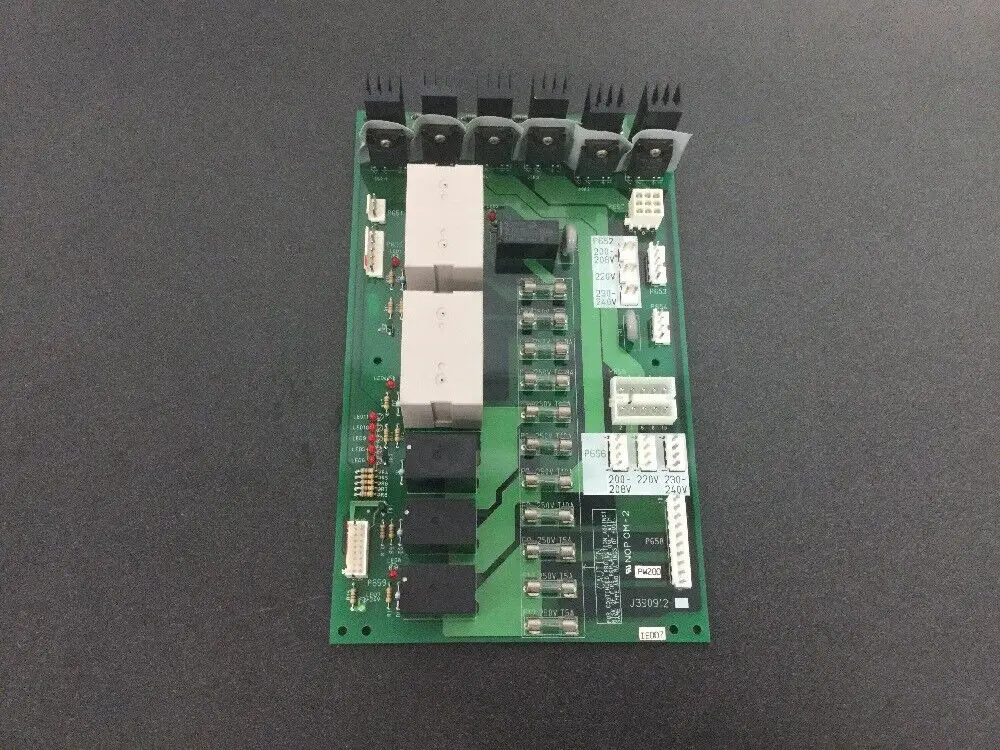

NORITSU QSS 3001/3011 minilab запасные части J390912-00 J390912 реле PCB

Высокое качество! Запасные части для струйного принтера чернильный демпфер DX5 печатающей головки Epson Mimaki Mutoh

Новые поступления

Новинки товаров от производителей по оптовым ценам