Пивоваренная установка Micro Breweri объемом 500 л Taproom яркий резервуар для

- Категория: Beverage & Wine Processing Machinery >>>

- Поставщик: Jinan Rainbow Machinery Co. Ltd.

Сохранить в закладки 1600467610705:

Описание и отзывы

Характеристики

Beer Brewing Equipment Brewery System Beer Equipment

500l Micro Breweri Brewery Plant 500l Taproom 500l Beer Bright Tank

Beer Brewing Equipment | ||||||||

Capacity Liters | 100L 200L 300L 500L 1000L 2000L 3000L 5000L 10000L ... | |||||||

Capacity BBL | 1BBL 2BBL 3BBL 5BBL 7BBL 10BBL 15BBL 20BBL 30BBL 60BBL... | |||||||

Heating | Steam Heating | Electric Heating | Direct Fire Heating | Others | ||||

Brewhouse | Mash Tank | Lauter Tun | Brew kettle | HLT/CLT | ||||

Fermentation | Fermenter, Brites, Unitanks | |||||||

Cooling System | Glycol Water Tank, Chiller, Pump | |||||||

CIP System | 2 tanks, 3 tanks, 4 tanks; with or without Heating | |||||||

Controller System | PID Digital Type, PLC, | |||||||

Keg & Keg Machine | EU USA kegs, and keg Washing/ Filling Machine | |||||||

Bottling | Semi-automatic Bottling machine, Automatic | |||||||

Others | Hop Gun, Yeast Tanks, Dry hop Doser, Hoses, Valves and pipelines... | |||||||

Brewhouse

Beer Brewhouse Configuration

2 vessels Beer brewhouse

3 vessels Beer brewhouse

Brewhouse

Vessels:

Regular: MLT+BKW+HLT.

Mash/Brew Kettle +Lauter & Whirlpool Tank.

Others: Mash, Lauter, Brew, Whirlpool, HLT, CLT

Vessels:

Regular: MLT+BKW+HLT.

Mash/Brew Kettle +Lauter & Whirlpool Tank.

Others: Mash, Lauter, Brew, Whirlpool, HLT, CLT

Heating Method:Steam Heating/Electric Heating/ Direct fire/Baine Marie

Specifications:

-With 30% Total Volume

-Dome top and cone bottom; bottom cone 160 degree

-Interior Shell: SUS304, T 3.0mm

-Exterior Shell: SUS304, T 2.0mm

-Insulation: PU/Rockwool T 100mm

-100% TIG welding with pure argon gas shield

-Interior Finish: 0.4~0.6μm/ Mirror Polishing

-Top mounted manhole

-360° CIP spraying ball

-Thermowell with high accuracy temperature sensor: PT100

-MLT with agitator with motor reducer, CE/UL Listed

-MLT with side manhole for spent grains

-With 30% Total Volume

-Dome top and cone bottom; bottom cone 160 degree

-Interior Shell: SUS304, T 3.0mm

-Exterior Shell: SUS304, T 2.0mm

-Insulation: PU/Rockwool T 100mm

-100% TIG welding with pure argon gas shield

-Interior Finish: 0.4~0.6μm/ Mirror Polishing

-Top mounted manhole

-360° CIP spraying ball

-Thermowell with high accuracy temperature sensor: PT100

-MLT with agitator with motor reducer, CE/UL Listed

-MLT with side manhole for spent grains

(For High Plato, the Lauter tank can be customized)

-MLT with easy-clean and detachable Sparging arm

-MLT with easy-clean and detachable False bottom

-BKW with tangential inlet for whirlpool function

Plate Heat Exchanger (China Top Brand)

-2 stages for Glycol water and City water

-SUS 304 Plates and frame

Optional:

-Grist Case;-Wort Buffer Tank;-Platform with Sink;-Flow meter;-Pneumatic Valves;-Others

-MLT with easy-clean and detachable Sparging arm

-MLT with easy-clean and detachable False bottom

-BKW with tangential inlet for whirlpool function

Plate Heat Exchanger (China Top Brand)

-2 stages for Glycol water and City water

-SUS 304 Plates and frame

Wort and HLT Pumps:-CE/UL Listed

Oxygenator

Brewhouse pipelines and Valves

SUS 304 Working Platform

Optional:

-Grist Case;-Wort Buffer Tank;-Platform with Sink;-Flow meter;-Pneumatic Valves;-Others

BEER FERMENTATION TANK

Beer Fermenting Vessel/Brites

-Total capacity: with 25% headspace

-Dome top and cone bottom, bottom cone, (60 degree for BFV)

-Interior Shell: SUS304, T 3.0mm;

-Exterior Shell: SUS304, T 2.0mm;

-Insulation: PU, T100mm

-100% TIG welding with pure argon gas shield

-Interior Finish: to 0.4~0.6μm/ Mirror polishing

-Cooling Jacket: both on cone and cylinder parts, T 1.5mm

-Top mounted manhole/Side manhole

-Relief/vacuum valve

-Dry hop port

-Thermometer

-Sample valve

-Bung apparatus with pressure gauge

-Test Pressure: 0.3Mpa, Working pressure: 0.15-0.2Mpa.

-Rotating racking arm on cone with butterfly valve

-Drainage with butterfly valve

-CIP arm with 360° spraying ball

-Thermowell with high accuracy temperature sensor: PT100

Optional:

Level Tube

CO2 Carbonation Stone

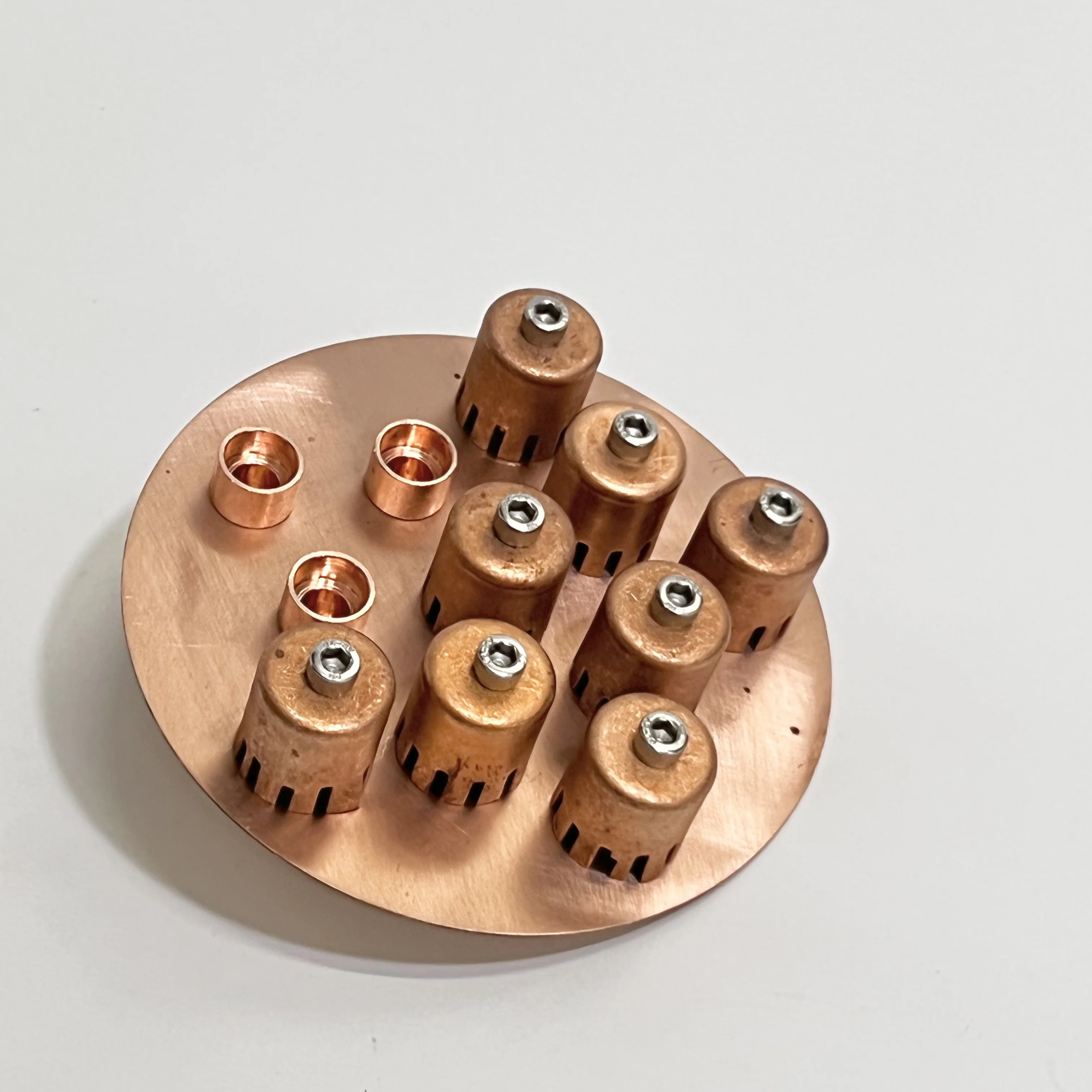

Copper Shell

Pressurized Hop drop feeder

Other requirements

Dimension design

-Dome top and cone bottom, bottom cone, (60 degree for BFV)

-Interior Shell: SUS304, T 3.0mm;

-Exterior Shell: SUS304, T 2.0mm;

-Insulation: PU, T100mm

-100% TIG welding with pure argon gas shield

-Interior Finish: to 0.4~0.6μm/ Mirror polishing

-Cooling Jacket: both on cone and cylinder parts, T 1.5mm

-Top mounted manhole/Side manhole

-Relief/vacuum valve

-Dry hop port

-Thermometer

-Sample valve

-Bung apparatus with pressure gauge

-Test Pressure: 0.3Mpa, Working pressure: 0.15-0.2Mpa.

-Rotating racking arm on cone with butterfly valve

-Drainage with butterfly valve

-CIP arm with 360° spraying ball

-Thermowell with high accuracy temperature sensor: PT100

Optional:

Level Tube

CO2 Carbonation Stone

Copper Shell

Pressurized Hop drop feeder

Other requirements

Dimension design

Похожие товары

1000 дистиллятор для виски

Лучшая фруктовая гидравлическая соковыжималка машина для прессования черничного

899,00 $ - 1 950,00 $

Оборудование для домашнего пивоварения машина приготовления пароварка

8,50 $ - 88,00 $

8 дюймов медь пузырь пластина для флейты алкоголя ректификационная

Промышленная электрическая соковыжималка для сахарного тростника по заводской

40L 50L из нержавеющей стали все в одном микро-пивоваренное guten домашнего пивоварения система заторный Чан микро пивоварня пиво

Коммерческая высокопроизводительная соковыжималка для сахарного тростника дизельный

2 200,00 $ - 2 500,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Рекламный надувной самолет украшение для костюма самолета ходячие костюмы продажи

C100 % восковая ткань с принтом китайские поставщики поставляют настраиваемые печатные африканские восковые ткани

0,93-0,97 $

Прямые продажи с фабрики могут быть оптовые складные тележки для покупок Удобные и уличные продуктовые

8,39-9,89 $

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $