Профессиональный высококачественный азотный генератор PSA производитель N2 газовое оборудование 23 года для пластиковой промышленности

- Категория: >>>

- Поставщик: CAN GAS SYSTEMS COMPANY LIMITED

Сохранить в закладки 1600467773924:

Описание и отзывы

Характеристики

Nitrogen grade requirements for plastics synthesis is 95-98% for injection molding processes, 99.5% for gas-assist injection molding, and 98-99.5% for blown film extrusion.

Nitrogen is widely used in the plastics industry. Injection molding, film extrusion, and gas-assist injection molding all use nitrogen because of its inertness and dryness. CANGAS On-site nitrogen is an ideal choice, as nitrogen can be generated on demand without relying on deliveries from a third party supplier.

In injection molding, moisture and oxygen can cause issues with the final product including defects and blemishes. Using dry nitrogen generated from a CANGAS on-site nitrogen generator eliminates these complications.

Gas assist injection molding (GIAM) involves a multi-step molding process. It is a way to make thick plastic parts without issues created from excess shrinkage of the part. It is a type of injection molding that uses inert gas to create a very dense and strong plastic part that uses nitrogen to pack out the part and compensate for shrinkage. First, the polymer is injected into a mold though not all filled. Nitrogen under high pressure is injected into the polymer, pushing it into areas of the mold that are not yet filled. The nitrogen pressure is maintained during the cooling phase of the molding process, and gas pressure is released and the part is ejected.

Film extrusion is achieved by extruding a molten thermoplastic using a screw through a die. Afterward, it is inflated to many times its initial diameter forming a thin tubular film. Screw carbonization and frequent die cleaning, caused by oxygen in the feed throat hopper, are issues with blown film extrusion that can be improved or eliminated by using a nitrogen purge

What Is Nitrogen Gas Purity?

Nitrogen gas purity refers to the proportion of a nitrogen gas that is present in a sample taken from its stream when compared to impurities present. Nitrogen gas can be categorized as high purity or low purity depending on the ratio of pure gas to the contaminants like oxygen, water vapor, carbon monoxide, and carbon dioxide.

This categorization based on nitrogen concentration plays a key role in determining the suitability of nitrogen to any industrial process.

CANGAS PSA( pressure swing adsorpiton) on-site nitorgne genertor -product gas technical indicators:

Nitrogen flow rate:5-8000Nm3/h

Nitrogen purity: ≥97%~99.999%

Nitrogen dew point:-20~-70℃

Nitrogen outlet pressure: 0.2~1.0Mpa (adjustable)

CANGAS PSA nitrogen production equipment is divided into: 95%,97%, 98%, 99%, 99.5%, 99.9%, 99.99%, 99.995%, 99.999%,99.9995 according to nitrogen purity, for your choice.

Nitorgen Genertor type: PSA N2 genertor , Membrane nitrogen genertor , Skid mounted type ,small box type ,container type, trailer type, truck type .

The adsorption tower has a special gas diffusion patented technology, which has a longer service life;

- Original molecular sieve composite bed structure to prevent molecular sieve poisoning;

- Blizzard combined filling technology, molecular sieve filling is more uniform and dense;

- Automatic compression device to avoid the phenomenon of molecular sieve powdering;

- Adopt Japan imported valves to ensure reliable operation of the equipment;

- Advanced technological process, fast equipment start-up time, saving energy consumption by more than 15%;

- Adopt intelligent controller (Siemens, Germany) to ensure long-term operation of the equipment;

- Imported molecular sieve is used, and the molecular sieve is guaranteed for ten years;

- Fully automatic operation, can automatically adjust the operating parameters according to the on-site gas consumption;

- Complete set of equipment assembly type with bottom frame, convenient and fast on-site installation;

CANGAS PSA N2 generator application:

Electronics industry: Nitrogen protection for semiconductors and electronic components

Atmosphere protection in SMT production

Heat treatment: bright annealing, protective heating, powder metallurgy and magnetic material sintering, etc.

Food industry: Equipped with LJ sterilizing filter, which can be used for nitrogen-filled packaging, grain storage, fresh-keeping of vegetables and fruits, and wine sealing and preservation.

Coal industry: underground explosion-proof and coalfield fire-fighting and extinguishing.

Chemical industry: nitrogen blanketing, replacement, cleaning, pressure conveying, chemical reaction agitation, chemical fiber production protection, etc.

Petroleum and natural gas industry: petroleum refining, nitrogen-filled purge and leak detection of containers and pipelines, and oil extraction by nitrogen injection.

Pharmaceutical industry: Nitrogen-filled storage of Chinese and Western medicines, pneumatic conveying of nitrogen-filled medicines, etc.

Others: metallurgical industry, rubber industry, aerospace industry, etc...

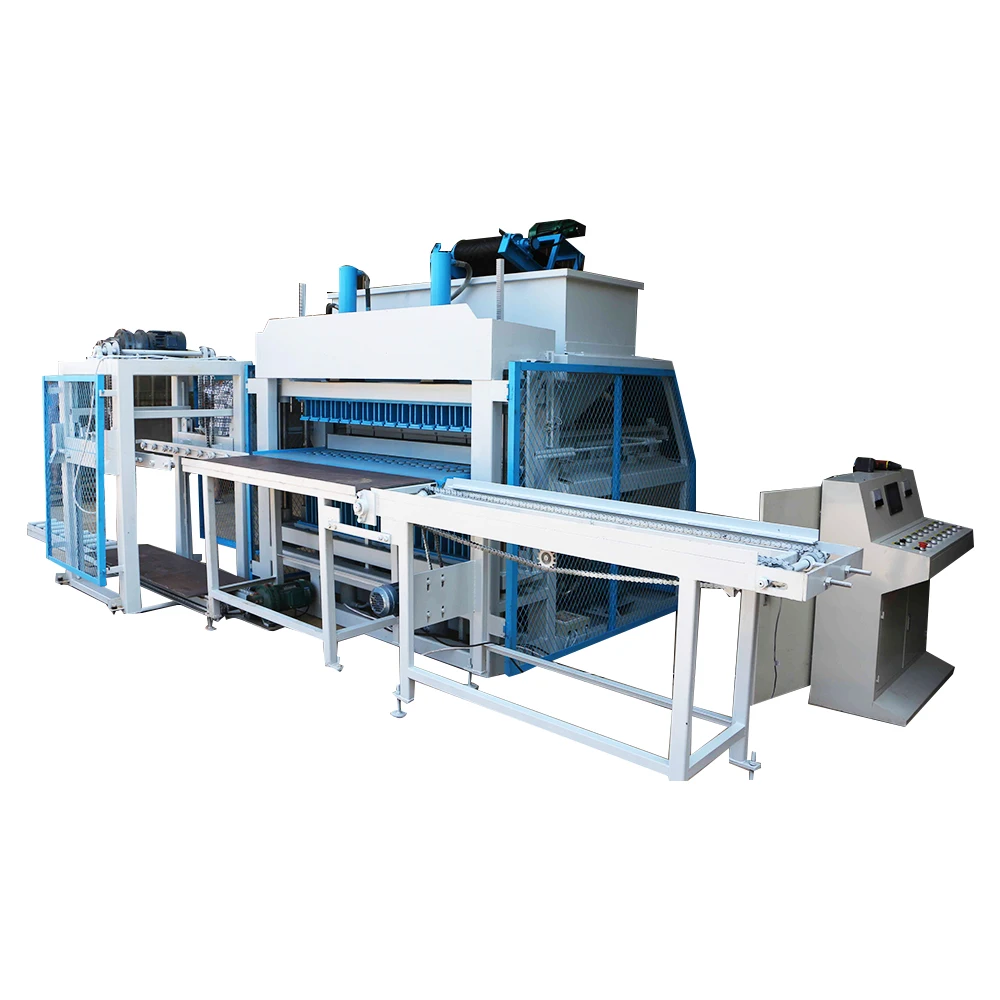

CANGAS CAPN PSA nitrogen generator equipment composition and functions of each part:

- Main components of nitrogen production equipment: 1. Air compressor, 2. Compressed air purification device, 3. PSA nitrogen production device, 4. Nitrogen detection device

- Two basic conditions required for nitrogen production:1. Compressed air 2. Power supply

- Air post-treatment and purification system: It is composed of a freeze dryer, three-stage precision filters for water, oil, and dust removal, and an automatic drain.

- Freeze dryer function:Freeze drying is used to remove water and cool air. The pressure dew point of the purified compressed air is 2-10℃, the oil removal rate is 99.999%, and the dust particles are less than 0.01u to ensure that the adsorbent is not polluted. Provide sufficient protection for carbon molecular sieve and ensure the service life of carbon molecular sieve.

- Air buffer tank function:Improve the continuity of the output airflow and the stability of the pressure.

- Pressure swing adsorption adsorption nitrogen production system:It consists of A and B adsorption towers, pneumatic valves, unqualified emptying and instrument control systems.

- The double adsorption tower performs alternate adsorption and regeneration, completes nitrogen and oxygen separation, and continuously outputs nitrogen.

- Automatic control system: It is mainly composed of programmable PLC controller, indicating instrument, on-line display of purity analysis, and unqualified alarm.

- Nitrogen buffer tank:Composed of nitrogen buffer tank and output pressure regulating valve. Function: The nitrogen output from the main engine system is injected into the nitrogen buffer tank to ensure the continuous supply of nitrogen and the output pressure regulating valve is composed. The pressure can be adjusted by the pressure reducing valve.

The Guarantee/Warranty Period shall be a period of twelve (12) months after on-site startup & commissioning or eighteen (18) months after shipment, whichever occurs first.

If any trouble or defect, originating with the design, material, workmanship or operating characteristics of any Goods, arises at any time during GUARANTEE/WARRANTY period, CAN GAS shall, at his own expense and as promptly as possible, make such alterations, repairs and replacements as may be necessary to permit the Goods to function in accordance with the specifications and to fulfill the foregoing guarantees.

Site service

CAN GAS can do paid services of on-site startup, commissioning, installation supervision, training, by providing purchaser with the services of qualified English-speaking engineers at users site, by sending English-speaking engineer to users site.

Похожие товары

резиновые уплотнительные полосы звукоизоляции уплотнительной ленты раковина печать

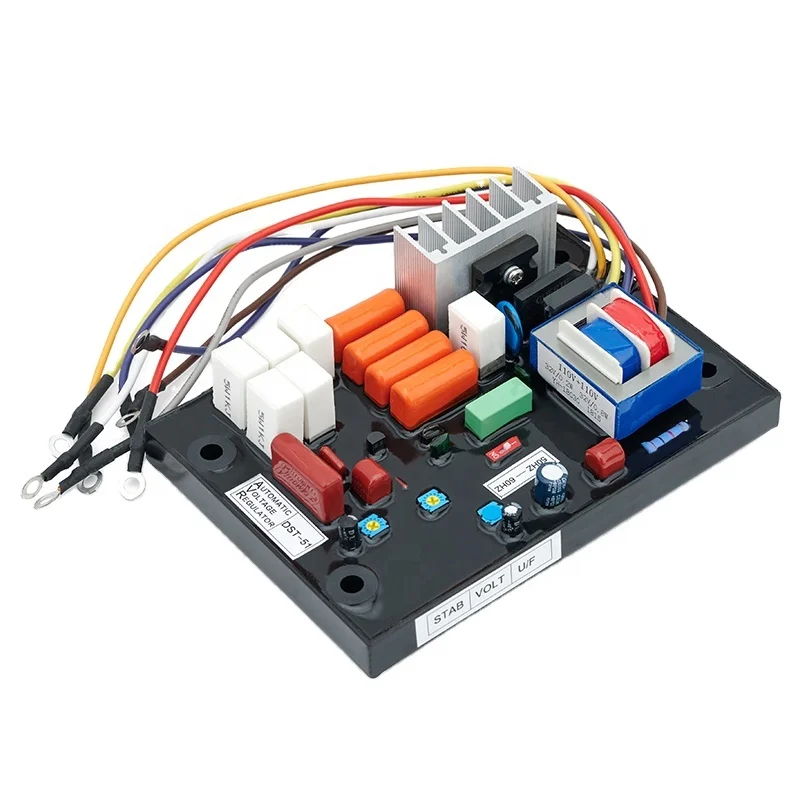

DST-51-DFKV taiyo автоматический регулятор напряжения 13000TE 26000TE

Механическое акустическое фортепиано 88 клавиш черного цвета

Автомобильный топливный насос для Audi A1 A3 для Volkswagen TOURAN GOLF V VI PASSAT B7 JETTA 1,4 TFSI 1,2 TSI 03C127026J 03C127026M

Светодиодная противотуманная лампа для дневных ходовых огней Vinstar E4, одобренная E70, E81, E82, E83N, E84, E87, E88, для BMW

20 Вт 30 Вт JPT MOPA волоконная лазерная маркировочная машина для цветной печати на металле нержавеющая сталь алюминий мощность Графический графический свинцовый

Автоматическая машина для изготовления проволочной сетки из нержавеющей стали, 2 - 5 мм

Новые поступления

Новинки товаров от производителей по оптовым ценам