Небольшая Заводская поставка пенопластовый бетононасос пенообразователь Бетономешалка

- Категория: >>>

- Поставщик: Wenzhou Dawn Machinery Equipment Co. Ltd.

Сохранить в закладки 1600470536545:

Описание и отзывы

Характеристики

Concrete Cement foaming machine for ground and roofing insulation

1.Machine introduction of Concrete Foam Machine

This line use the technology of pump transportation.The whole process line include four parts: feeding conveyor, concrete mixing

machine, foam machine used in block , foam agent and pump, the transportation capacity is 10~15m³/h, the max level transportation

distance is 50m, the max horizon distance is 400m.

Applications:

Floor/roof casting

Block

Wall panel

Framed wall and house structure casting

Subway and coal mining backfill

Machine features:

1).the machines is with wheels, then the process line is easy to move, so it can be used for many places, such as construction

plant, block plant, and so on.

2).Light weight, the main machine is only 600kg, you also can equip with the forklift, it will save more time, labour and costLow

consumption, the whole line is about 15kw.

3).Use the pump to transport the cement foam

It can use plant type foam agent, animal type foam agent and synthetic foam agent.

You can adjust the volume of the raw material.

Features:

This is foam cement insulation panel making machine.This production line is used to make foam cement blocks of different dimension. An entire production line includes cement feeding machine, mixing machine, foaming machine and mortar pump. It's easy to operate with stable performance. Both the whole system or one part of the system are available.

1).the machines is with wheels, then the process line is easy to move, so it can be used for many places, such as construction plant, block plant, and so on.

2).Light weight, the main machine is only 200kg, you also can equip with the forklift, it will save more time, labor and cost. Low consumption, the whole line is about 15kw.

3).Use the pump to transport the cement foam, it can use plant type foam agent, animal type foam agent and synthetic foam agent. You can adjust the volume of the raw material.

4)Both 220V voltage and 380V are OK for this machine.

5)Easy operating, One-button-start system makes it easy to operate this machine.

Advantages of foam cement insulation panels made by our machine:

1.Foam cement insulation panel has an excellent soundproof ability.

2.High thermal insulation rating. It can keep indoor temperature in a proper range, reduceing air conditioning cost by 30%.

3.Earthquake Resistant:

Effect of earthquake on buildings is proportional to the weight of the building, as a result, foam cement insulation panel shows an excellent resistance to earthquake. Regions of high seismic like Japan exclusively use it.

4. Saving floor Space Area:

Use of thinner blocks (6" instead of 9" exterior walls) because of its excellent water barrier & insulation properties leads to an increase in floor space area between 3-5%.

5. Cost saving

Being lightweight foam cement drastically reduces the dead weight of building, resulting into reduction of steel (up to 27%) and cement (up to 20%) structural cost saving. Being 8 times the size of a clay brick, foam cement wall construction involves 1/3 the joint, thus an overall mortar saving up to 66%.

Its automatic manufacturing process gives foam cement an exceptional dimensional accuracy & smooth surfaces, eliminating need of three-coat plaster walls and allows for a final 6 mm skim coat (putty/POP).

6. Fire Resistant

Best in class fire rating of 4 hours. The melting point of foam cement panel is over 1600 ºC, more than twice the typical temperature of building fire (about 650 ºC).

7. Water Barrier

Its structure does not allow capillary action, making it impervious to water. Its water barrier properties are further enhanced by adding cone based additives.

9. High Strength

High pressure steam-curing gives foam cement panel unbelievable strength, even higher than M150 concrete.

Application of the foam cement:

1. Floor/roof casting

2. Block making

3. Wall panel

4. Framed wall and house structure casting

5. Subway and coal mining back filling.

Description:

1.The power of the device is use the compressed air,with the short time,the foam is the independent mesh bubble,and it is with rich foam, fine and large quantity.and the capacity can reach 30-40m³.

2.The weight is light,it is convenient to move or hang to floor for construction.

3.It is easy to operate, the bubble can be produced as switched on.

4.The foam is exquisite even as the cheese,All kinds of foaming agent both at home and abroad can be used.

5.The power can be adjusted based on customer request,and reduce the noise, reduce the dosage of the foaming agent, and can reduce power consumption.

6.It is widely used in:foamed concrete cut into parts, light wall space, fire prevention door plank core chlorine magnesium oxide and glassy magnesium foamed cement production line of the environmental protection such as composite duct foaming auxiliary equipment,and with the character of large amount of foam, use convenient, etc.

Portable model cement foam generator

Characteristics foam cement mixer :

1.The power of the device is use the compressed air,with the short time,the foam is the independent mesh bubble,and it is with rich foam, fine and large quantity.The weight is light,it is convenient to move or hang to floor for construction.

2.It is easy to operate, the bubble can be produced as switched on.

3.The foam is exquisite even as the cheese,All kinds of foaming agent both at home and abroad can be used.

4.The power can be adjusted based on customer request,and reduce the noise, reduce the dosage of the foaming agent, and can reduce power consumption.

5.It is widely used in:foamed concrete cut into parts, light wall space, fire prevention door plank core chlorine magnesium oxide and glassy magnesium foamed cement production line of the environmental protection such as composite duct foaming auxiliary equipment,and with the character of large amount of foam, use convenient, etc.

Specification:

| Model | LM-F10 | LM-F20 | LM-F30 | LM-F40 | LM-F50 | LM-F60 |

| Mortar pump | Screw mortar pump | Double hydraulic pump | ||||

| Pump power | 5kw | 15kw | 22kw | 30kw | 45kw | 45kw |

| Vertical | 40m | 80m | 100m | 120m | 150m | 180m |

| horizontal | 300m | 600m | 800m | 1000m | 1200m | 1400m |

| Capacity | 10m³/h | 20m³/h | 30m³/h | 40 m³/h | 50m³/h | 60m³/h |

| Outlet pressure | 1mpa | 8mpa | 10mpa | 14mpa | 16mpa | 16mpa |

| Dimension | 1500*950 *800mm | 2300*950* 1600mm | 2500*1050* 1800mm | 3200*1500* 1400mm | 3500*1600* 1800mm | 3500*1600* 1800mm |

| Weight | 300kg | 1100kg | 1300kg | 1600kg | 2200kg | 2400kg |

| Squeeze Mortar Pump | Gypsum Based Self Leveling | Mortar Grouting Pump | Cement Foaming Machine |

|  |  |  |

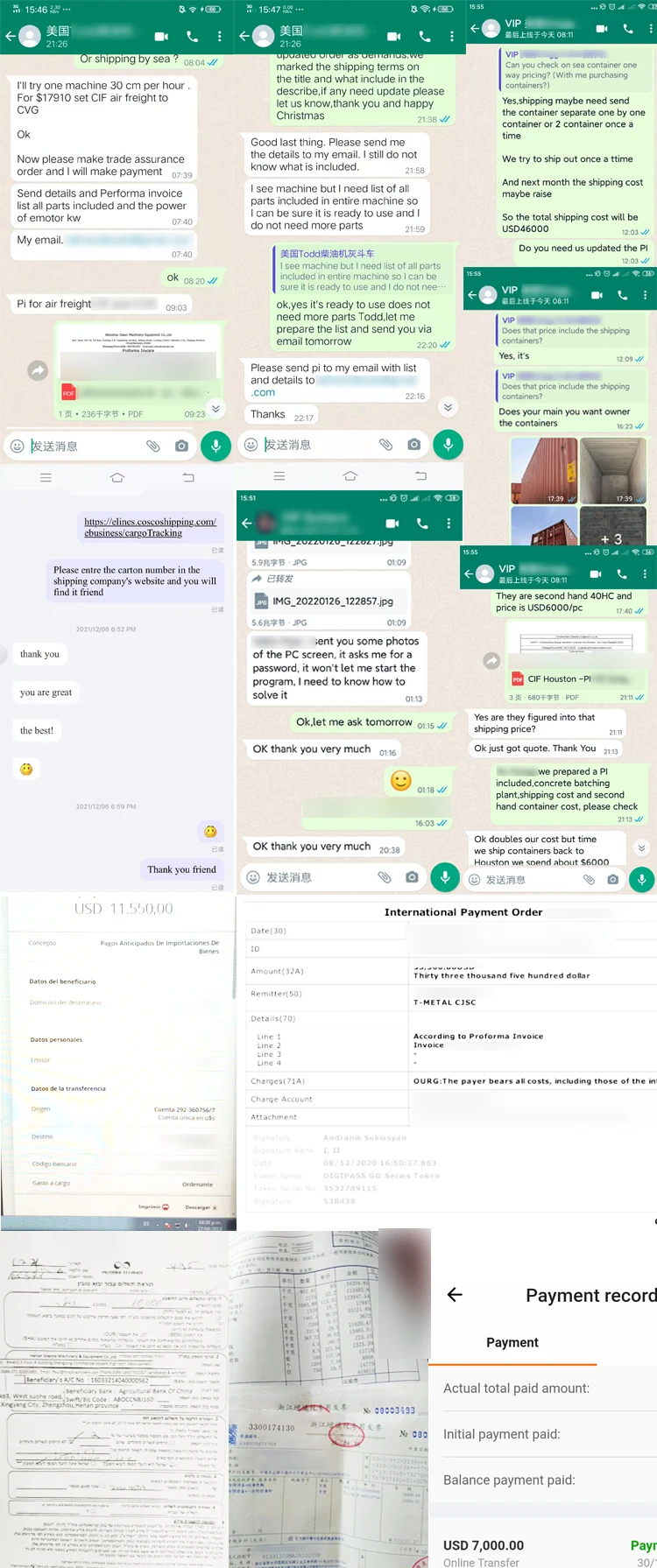

Feedback And Orders From Some Customers

Before sales services:

2. Offer design drawing and solution accroding to users' demands.

During sales services:

1. Produce and ship the goods for customer safe and timely;

2. If need, arrange engineer to train works how to operate the machine rightly.

3. Highly inspecting equipments in every working procedure, quality comes first;

After sales services:

1. Give a clear reply upon customers questions within 24 hours;

2. If necessary, we send engineer to user's site to solve the problem timely;

3. Reture visti at regular intervals;

4. Establishing user's record;

5. One year guarantee and whole life services and techinal support;

6. Supply latest industrial informaion.

1.You are the trading company or manufacture company ?

we are the 10 years' manufacture experiences manufacture company in China.

A.Our machine can make the foaming , mix , pump together.

B. Our machine can automatically adjust the density.

C. Our foam concrete machine can easy to control and operate .

From 300-800kg/m³ , if your have any other requirements , we can try to satisfy you .

We have our professional testing department ,we will have twice testing when we finish our machine and before shipping.

The warranty will be one year from the date of shipment. Any detected parts during this period caused by the quality of products

will be replaced by seller free of cost (exclude wear and tie parts), improper operation and other manmade reasons are excluded.

Похожие товары

Шины для самолетов 660x200-335 16PR

Официальный экскаватор XCMG XE35U China CE 3 5 тонн импортный

Влажная салфетка, смачивающая машина, машина для производства влажных салфеток с машиной для производства спирта

Светодиодный сенсорный выключатель, экранирующий Индуктивный выключатель, используемый для освещения шкафа

FRT009 модель человеческого скелета, полубоковая окраска 85 см с отметкой происхождения и окончания мышц для медицинской науки

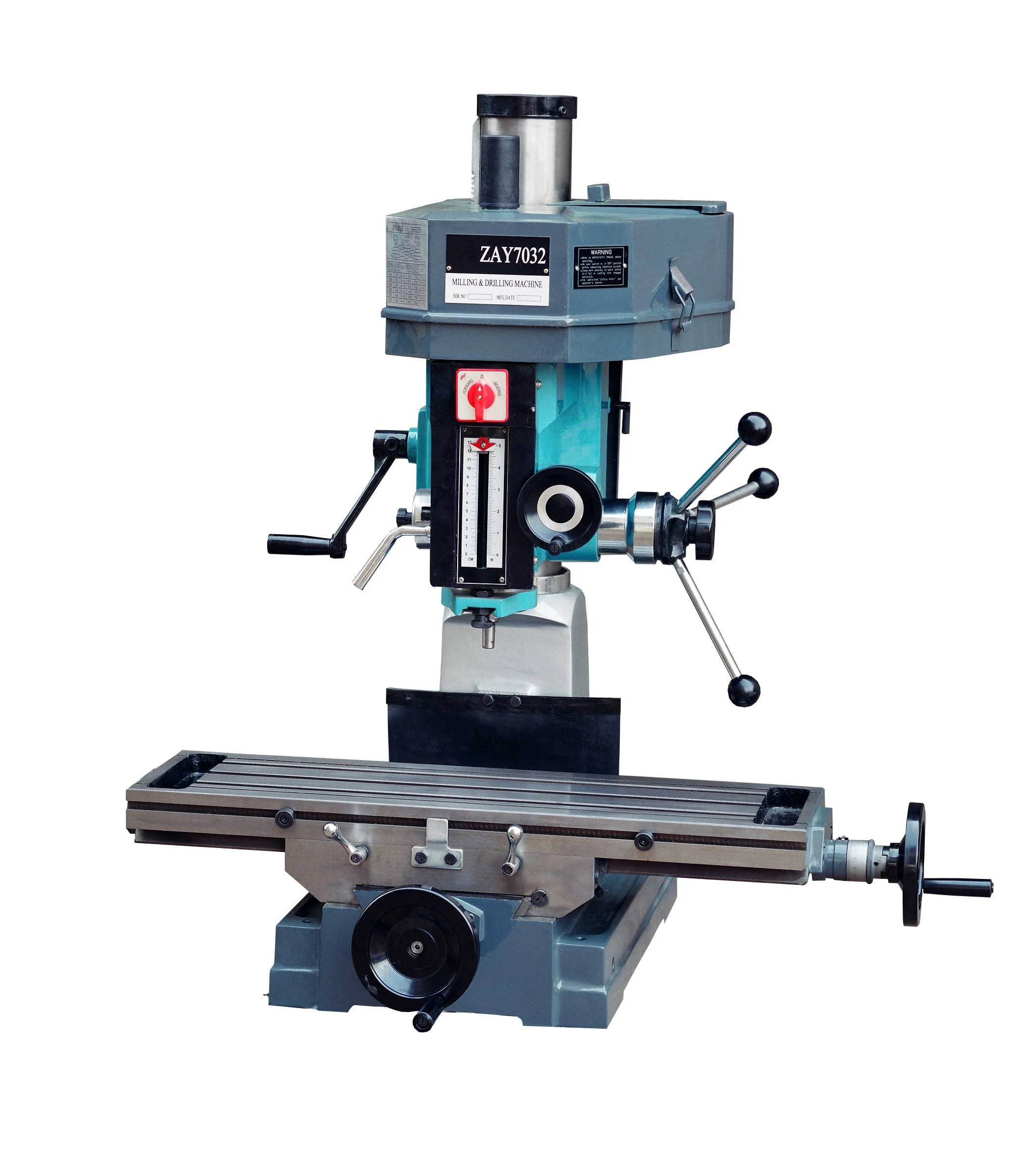

Ленточная головка, дешевый сверлильный и фрезерный станок, зея7040

ZONEKO Лучшая цена Высокое качество gun81Cross Универсальный поперечный подшипник для MITSUBISHI Truck GUM-81

Новые поступления

Новинки товаров от производителей по оптовым ценам