Завод Shanghai paixie новое состояние стабильное функционирование автоматическое оборудование для розлива жидкого пигмента

- Категория: >>>

- Поставщик: Shanghai Paixie Packing Machinery Co. Ltd.

Сохранить в закладки 1600471797643:

Описание и отзывы

Характеристики

Shanghai Paixie Packing Machinery Co.,Ltd is a professional manufacturer of filling line for over 12 years, customized filling lines for different industry customers like food and beverage, cosmetic, medical industry, chemical industry and etc, lots of successful cases for your reference. The full automatic liquid filling machine is designed for saving time on adjusting and testing machine, it can fill liquid or paste accurately by entering a certain filling volume. The PLC control method makes it easy to operate and thigh speed working efficiency is ideal for different scale production. It can work with the automatic capping machine and labeling machine and other equipment based on customer requirement. PAIXIE filling line is widely used in the following industries:

* Beverage Filling Machine Line (such as water, juice, beer, liquor, vodka, wine etc.)

* Food Filling Machine Line (such as honey, sauce, oil, chocolate, vinegar etc. )

* Chemical and Pharmaceutical Filling Machine Line (such as syrup, eye drop, alcohol, reagent, ampoul, syringe etc. )

* Cosmetics Filling Machine Line (such as perfume, body spray, nail polish, cream, lotion, detergent, hand gel etc. )

* Food Filling Machine Line (such as honey, sauce, oil, chocolate, vinegar etc. )

* Chemical and Pharmaceutical Filling Machine Line (such as syrup, eye drop, alcohol, reagent, ampoul, syringe etc. )

* Cosmetics Filling Machine Line (such as perfume, body spray, nail polish, cream, lotion, detergent, hand gel etc. )

Fully automatic pigment liquid filling and capping machine has passed CE&ISO 9001 certification. The machine is suitable for glass or plastic bottles of different sizes and shapes, and is suitable for different filling volumes. By adjusting the filling volume via the touch screen, liquid can be filled quickly and with high precision. Widely used in small bottle filling of essential oils, eye drops, perfumes, nail polishes, lotions, etc.

Product | Automatic liquid pigment filling machinery industry equipment |

Output | 1000-6000BPH, or customized |

Filling Volume | 10-100ml, or customized |

Air compressor | 0.6-0.8Mpa |

Filling Material | Color |

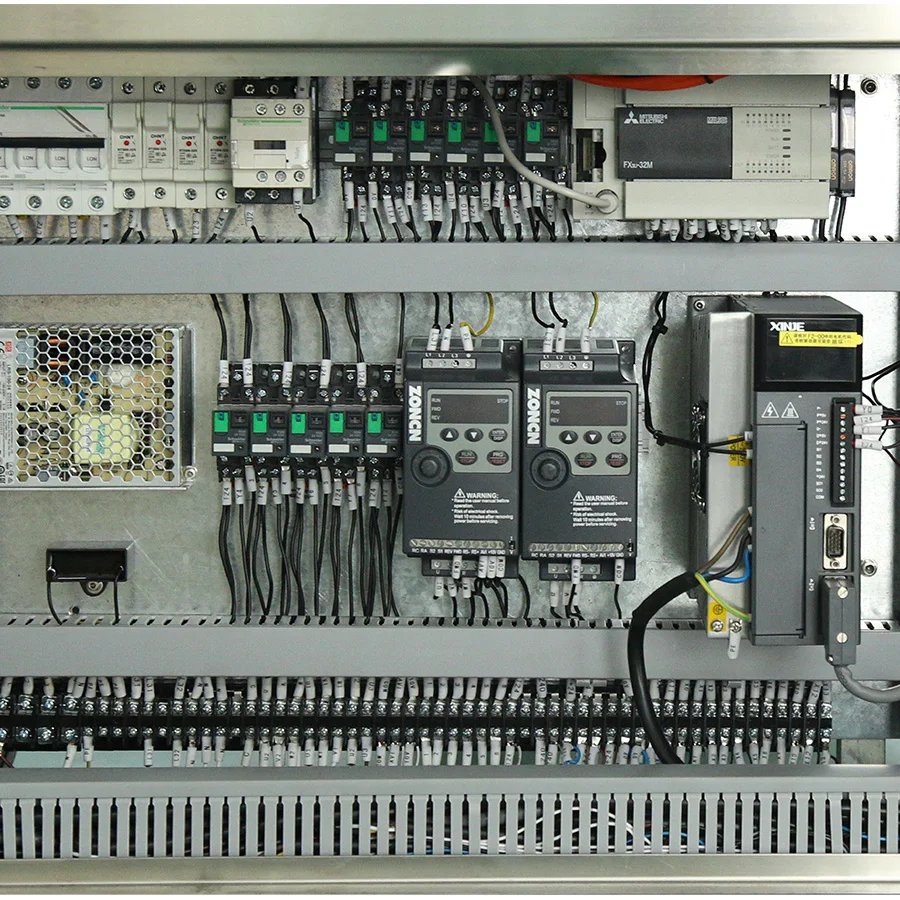

Control | PLC and Touch Screen |

Driving Motor | Servo Motor |

Capping motor | Magnetic motor |

Torque | 0-100N |

Detection | Photocell |

Filling Type | Piston Pump, Peristaltic Pump |

Power | 1.5KW |

Material | SS304 |

Capping Head | Screwing, Pressing, Crimping Head ( According to the cap type) |

Suitable Industry | Cosmetic, medical, food, detergent, etc |

Human protection | Complete safety switch alarm |

Cap type | Chubby Gorilla bottle |

Frequency speed turntable is used to input bottle automatically

Bottle feeding table

Variable speed rotary bottle feeding table is the basic feeding system of filling line, operator will put empty bottles on the

table, with gear motor driving, the bottle will be arranged to smarter filler input interface correctly. With flexible output

tunnel, the machine will be able to work with different size bottle.

table, with gear motor driving, the bottle will be arranged to smarter filler input interface correctly. With flexible output

tunnel, the machine will be able to work with different size bottle.

How to work with Big bottle without the table ? I want to be convenient

Ynscrambler for big bottle

Conveyor hoister

Direction adjustment

Combination of the unscrambler and feeding table

To save budget cost , most customer select to run 10 ml with unscrambler , others are feed by rotary table .

How to ensure fast filling speed and high precision ?

This is wheel type piston pump filling machine which is designed for small bottle and low capacity filling task, driven by servo motor with high precision. The filling nozzles are made of SS316, resist high temperature filling. drip-proof , via photoelectric detection to ensure no bottle no filling.

Servo motor driving

Different from traditional air driving , paixie customize machine by servo motor , it is contributed to precision control and different volume change ,everything will be done by HMI adjustment

Servo filling station construction

1- High precison , we control the servo motor by PLC , the servo contected with the piston pump by screw , the motor running up ,push the screw , then screw push piston at the opposite , so actually the filling volume is equal to motor running distance .

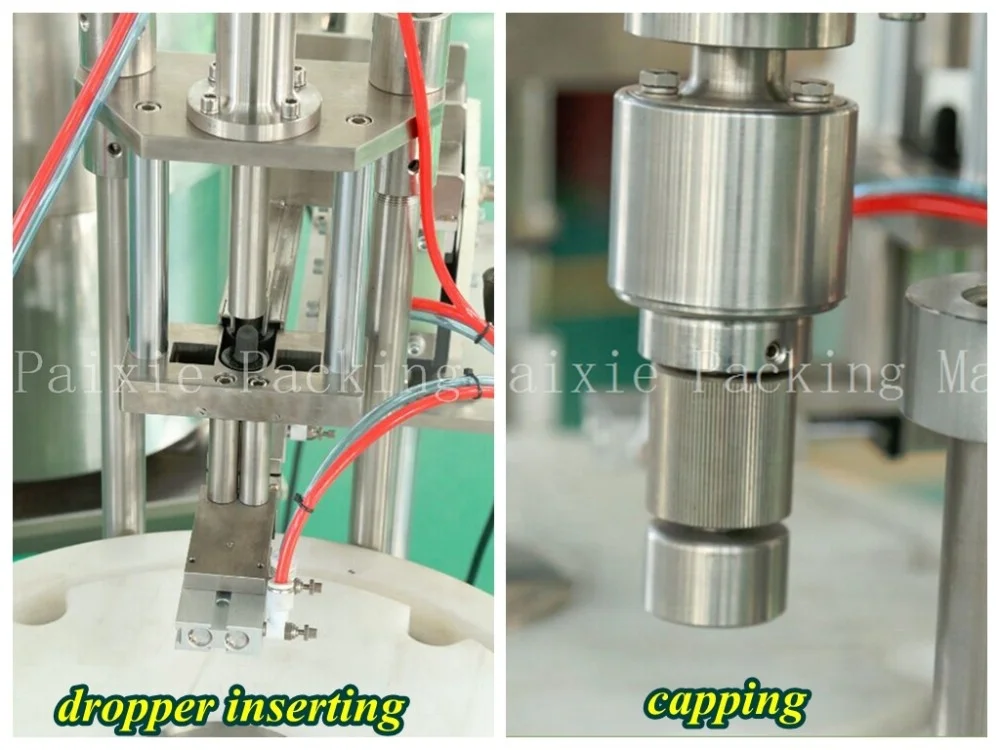

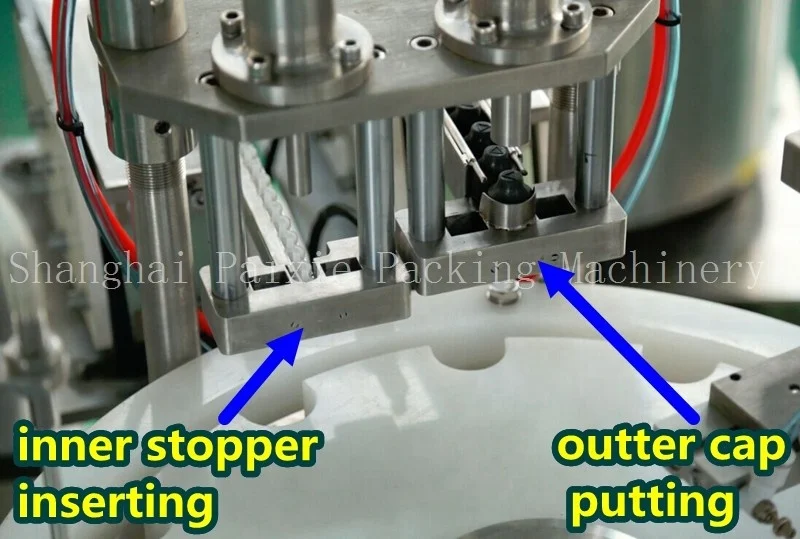

How to have the cap to be inserted accurately ?

Caelevator

With the customzied mold , all format spray can be inserted into bottle accurately

Cap inserting station with mold

With the customzied mold ,all formats dropper can be inserted into the bottle accurately

Vibrator construction

By replace the top hopper , we are able to work with different caps

How to Ensure the capping torque and protect from broken ?

Three-jar capping head application

The three-Jaw capping head is the newest design for different cap size , it is easy adjusted .

Magnetic cap torquing motor

To be different from traditional capping motor , Paixie uses magnetic motor in torquing , you can set all power as the cap need so that we prevent cap from broken or liquid leaking beucase of toure over or few

How to replace bottle from one format to another format ?

We do bottle star wheel for each size bottle , that is the only part you have to replace , one bottle one wheel .

Похожие товары

Импульсная Портативная Лазерная Очистительная Машина 100 Вт 200

2 200,00 $ - 3 800,00 $

Горячая Распродажа лабораторная высокоскоростная небольшая горизонтальная центрифуга-машина для очистки сточных

11 000,00 $

Аксессуары для автоматических ворот шестеренка раздвижных хорошее

Заводская Цена Автоматический Вакуумный и журнальный комбо PCB погрузчик с регулировкой ширины 460

Полуавтоматическая машина для выдувного формования ПЭТ

Машина для производства пластиковых гранул Pp Pe Pc Pbt Abs Pvc пластиковые гранулы двухшнековый экструдер

60 000,00 $

Композитная фаски машина для линейного радиуса и неправильной

350,00 $ - 400,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $