Лидер продаж линия продольной резки включает резку до длины машина для декойлер и отвод/40 м Автоматическая продольная резка стальных

- Категория: >>>

- Поставщик: Cangzhou Zhongheng Machine Manufacture Co. ltd.

Сохранить в закладки 1600481978662:

Описание и отзывы

Характеристики

Simple Slitting Line /Automatic Steel Coil Slitting Machine and Cutting to Length Line Machine

Product Application

To slitte strips from the bigger width of material .

Part 1 Hydraulic Decoiler

Part 2 Leveling and cut to length

Leveling machine has 5 roller up and 6 rollers down

Motor AC 7.5KW

Crop shear: Drive by oil hydraulic cylinder, cut off the crude steel plat head for following processing.

PART 3 Slitting Machine

Adopts Japanese Circle cutter, can shear different

Size strips .

Main axis material 40CR, diameter Φ240mm

Blade material: Cr12Mov

Motor :30 KW

Strips size adjustable

PART 4 Tension Device

separated steel strip, which form a certain tension before send to the recoiler, to complete winding operation

PART 5 Recoiler

collect the steel strip after slitting closely

Motor: 22KW

Capacity 15 Ton

PART 6 Scrap recoiling machine

collect the trimmings cutting from the slitting machine

Other Machine

We provide an extensive line of products, including: roof and wall panel machine, tile roof machine, purline forming machine,shutter door machine, floor decking machine and other associated equipment. Our roll forming machines are equipped with PLC control to ensure high accuracy and easy operation.

A: Yes. We have an experienced engineers to work out the most suitable design and production plan for the machine.

2: How can we be assured that you will deliver us quality machine with spare parts?

A:1. Customers to send the technical people to our factory for checking the quality.

2.We can send the technicians to the buyer`s factory for the installation and trainning .

A: Within the One-YEARS period, we could supply you the replacement parts for free .

If any damaged parts caused by quality problems after two years,we will also help but customer pay the cost ..

About ZHONGHENG

CANGZHOU ZhongHeng Machine Manufacture Co.,ltd is a professional manufacturer and exporter which has its own factory and also cooperate with several production factories and associated enterprises, concerning with the design, development and production of cold roll forming machines,material of building. We specialize in the automated production line of sheet cold roll forming machines. We are able to provide an integral resolution schema of cold roll forming system through a combination of advanced system design and equipment. Based on our advanced research and commercial team, we are able to research and development, manufacturing and sale of standard and non-standard cold roll forming equipment for our clients world widely.

Похожие товары

OEM завод 220V дизельный генератор

Хвост собаки кошки вашему ребенку выбрать тип одеяния замшевые пальто для собак

Сосновые двери бразильские готовые деревянные двери Цена Компактная ЛАМИНИРОВАННАЯ ДВЕРЬ для туалета

Купол из прозрачного стекла разных размеров с деревянной основой для рождественского подарка

Зубчатый резак HSS с сертификатом TUV

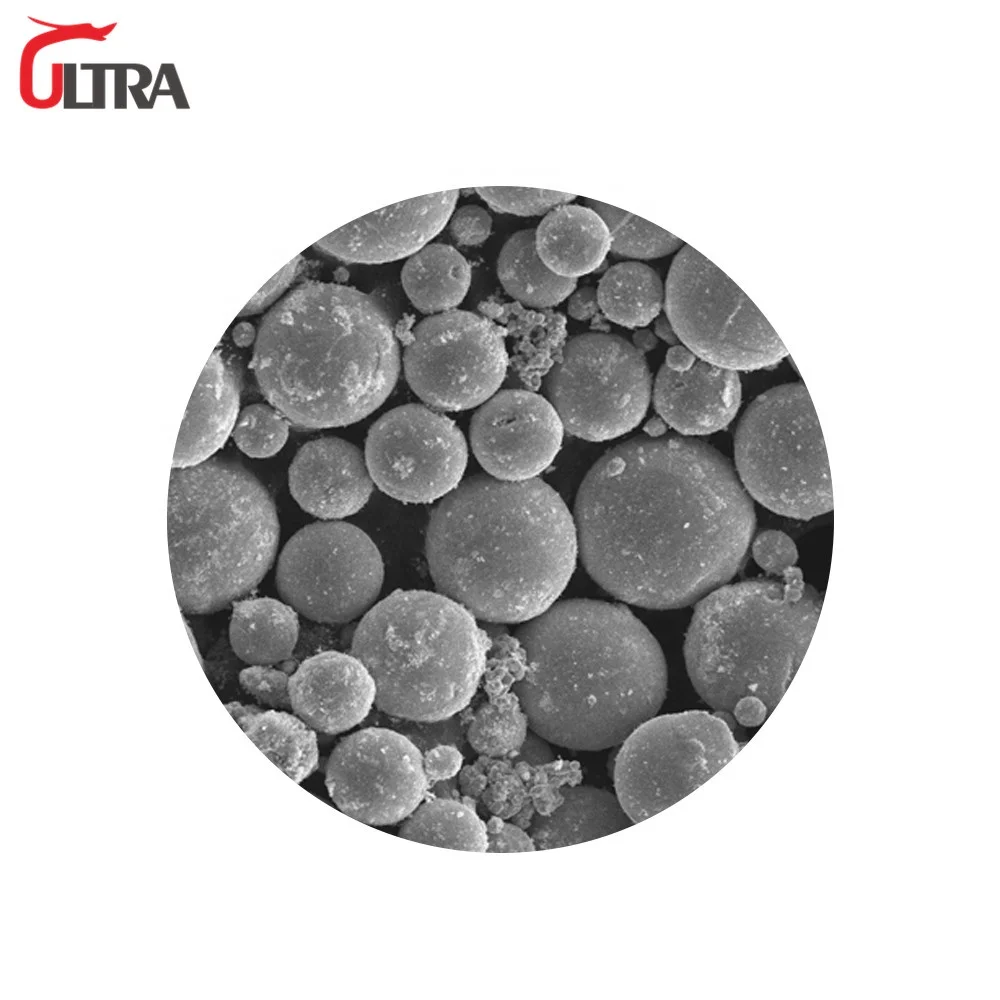

Сферический вольфрамовый порошок для 3d-печати, вольфрамовый порошок, 99.9% чистый, Сферический вольфрамовый порошок, надежные поставщики

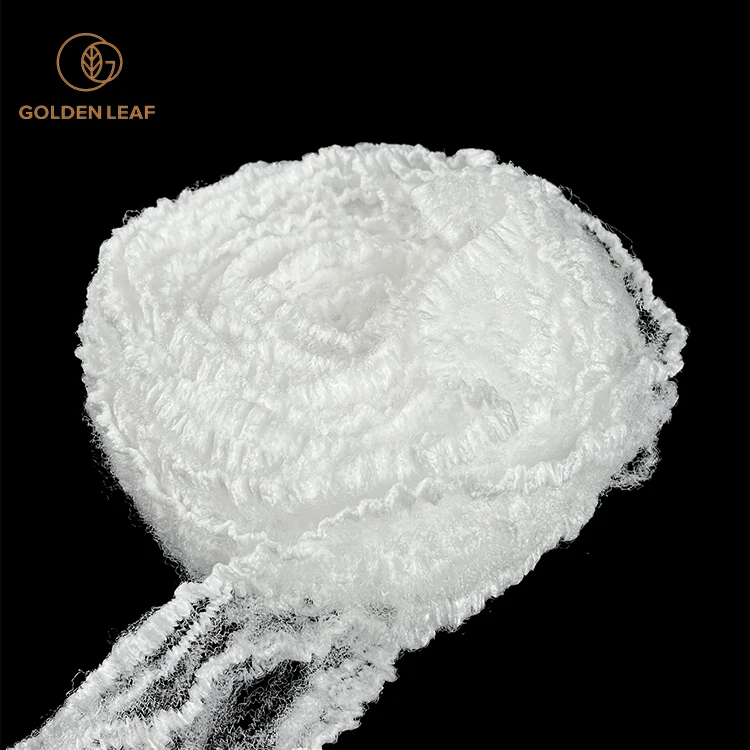

Лидер продаж, пищевые чистые неотбеленные полипропиленовые тяги для сигаретных фильтров

Новые поступления

Новинки товаров от производителей по оптовым ценам