QT4 40 асфальтоукладчик формируя машину взаимосвязанных бетонных блоков пресс формы

- Категория: >>>

- Поставщик: Shandong Brick Machinery Co. Ltd.Shandong Ltd.

Сохранить в закладки 1600483112514:

Описание и отзывы

Характеристики

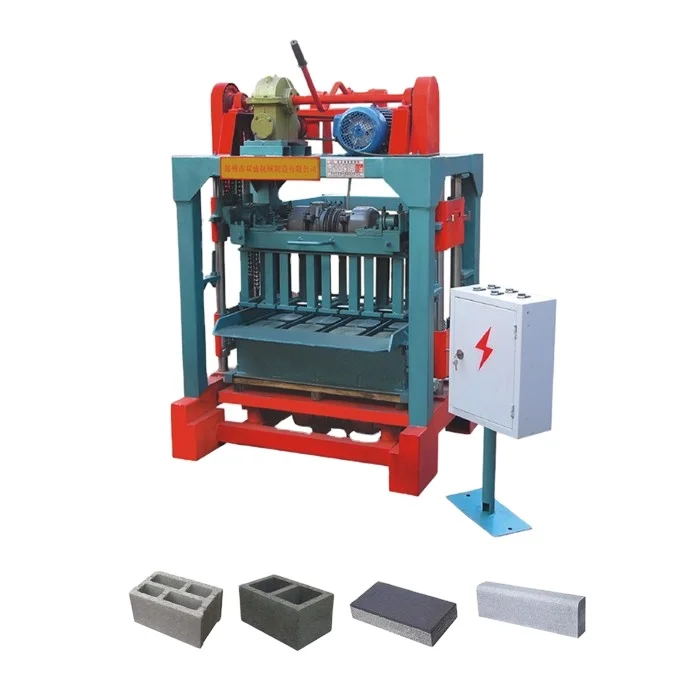

QT4-40 paver forming machine interlocking concrete blocks molds

Product Description:

QT4-40 paver forming machine is created based on original block molding machine withtechnological innovation and development, Its design is reasonable, excellent performance. This machine equipped with super vibration motor, The production of blocks are of good quality,large density and high strength. adopting manual pushpull mold, artificially packing material,simple operation, save energy, finished brick faster, low labor intensity.

Main technical parameters:

Dimension of host machine | 1350*1460*1800mm |

Host Machine Weight | 1500KG |

Main Vibration | Platform vibration |

Voltage | 220/380/415/440V(Customized) |

Pallet size | 880*480mm |

Molding cycle | 40s |

Motors Power | 9.55KW |

Raw Materials:crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes.

Applied Products

concrete blocks:solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc.

Applied Fields :widely used in buildings, road pavings, squares, gardens, landscaping, city constructions, etc

Main Advantages:

1.Small invest, high returns.

2.Can produce different blocks by changing moulds.

3.The mould are treated by high temperature carburizing. The service life three times longer than normal one

Production capacity :

QT4-40 paver forming machine Production Hydraulic Press Cement Concrete Brick Block Making Molding Machine produce different type blocks just changing moulds, It can produce hollow/solid blocks, riverside bricks, revetment bricks, square bricks, grassed bricks ,paver, interlocking blocks,curbstone,colored paver,etc with different moulds.If you have special shape,our engineer also can special design mould for you.

| Block | Size/mm | Moulding Cycle | Qty/Mould | Qty/Hour | Qty/8Hours | |

| Hollow Block | 400x200x200 | 35-40s | 4pcs | 300-360pcs | 2400-2880pcs | |

| Hollow Block |  | 400x150x200 | 35-40s | 5pcs | 360-450pcs | 2880-3600pcs |

| Hollow Block |  | 400x100x200 | 35-40s | 7pcs | 500-630pcs | 4000-5040pcs |

| Hollow Block |  | 400x150x200 | 35-40s | 5pcs | 360-450pcs | 2880-3600pcs |

| Poroue Block |  | 240x115x90 | 35-40s | 9pcs | 720pcs | 5760pcs |

| Solid Block |  | 240x115x53 | 35-40s | 21pcs | 1900pcs | 15200pcs |

| Paver |  | 225x112.5x60 | 35-40s | 9pcs | 700-800pcs | 5680-6480pcs |

QT4-40 paver forming machine interlocking concrete blocks molds

QT4-40 paver forming machine interlocking concrete blocks molds

Raw materials:

Raw materials are generally cement, sand, gravels, crushed stone powder, slags, fly ash, ect, depending on customers' choice.

A. 8-10% cement, 30-40% sand, 50-60% crushed stone

B. 8-10% cement, 30% flyash, 60% sand or stone powder The diameter of sand and stones need to be less than 15mm, if produce paver interlocking brick, need color iron.

QT4-40 paver forming machine interlocking concrete blocks molds

Customer Site:

Packing and deliver :

Packing shall be wrapped with plastic film or according to the customer's require.

1. The whole brick machine production line is mainly full container shipping,

2. Wrap the whole brick machine with plastic film before shipment to prevent water or moisture,

3. Then load the brick machine into the container with a forklift,

4. During loading, tighten the machine with the reinforcing ring in the container to avoid damage caused by transportation bumps on the brick machine.

Our services:

Pre-sale service

1.Professional advice on raw material and site selection.

2.Seletion of the most suitable machine.

3.24 hours online service.

4.Welcome to visit our factory at any time .

On sale service

1.Update the production scheduling in time

2.Quality supervision

3.Product acceptance and testing

4.Shipping on time

After sale service

1.Free online guidance and tutorials

2.Professional engineer training service

3.One year quality guarantee period.

4.Regular return visits to customer usage

Company information:

Contact US:

Похожие товары

QT5-15 популярная в Африке машина для формования блоков бетонный цемент кирпич цена строительная автоматическая

QT5-15 машина для изготовления цементных блоков и пресс-форм формовочная строительных форм продажи полностью автоматическая

Сменные формовочные блоки делая машину без QTJ4-40 формования бетонных блоков машина для производства Цементных Блоков

Лидер продаж 4-35 бункеров машина для изготовления цемента не горящего кирпича многофункциональная формовочная

Автоматический полый гипсовый Перегородочный блок пресс-формы

HFB546 HONGFA машина для укладки кирпича и яиц

Популярная электрическая автоматическая подъемная Мобильная машина для колодца цементный люк круглый блок кирпичная продажа

Новые поступления

Новинки товаров от производителей по оптовым ценам