Установка для извлечения соевых растворителей 50TPD n hexane с остатками масла менее 1%

- Категория: >>>

- Поставщик: Zhengzhou Sinoder Indutech Machinery Co. Ltd.

Сохранить в закладки 1600487310673:

Описание и отзывы

Характеристики

50TPD n-hexane soybean solvent extraction plant with less than 1% oil residue

Brief introduction of solvent extraction plant

The solvent extraction plant is part of vegetable oil processing plant which is designed to extract oil directly from oil seed containing less than 20% oil like soyabean fter flaking or it extracts oils from prepressed or fully pressed cake of seeds containing more than 20% oil like sunflower ,peanut ,cottonseed , palm kernel ,canola, copra ,castor, and variety of other vegetable seed raw material

Main equipment and function :

(1) Solvent pumps: continuously spray solvent to the rotary-type extractor;

(2)Rotocel extractor: Spray and soak the pre-pressed cake with solvent so that oil fats can be

dissolved in solvent(form miscella). After processing, you can get wet meal and miscella (mixed oil).

(3)DTDC: usd to separate the solvent from the wet meal.

(4)Miscella tank 1st: pump the miscella (oil with solvent) in to the miscella 1st , and then add 10%

saline water to it. The phospholipid and impurities in the miscella will react with the saline wter,

at last the reactant precipitate, reaching the goal of purifying.

(5)Miscella tank 2nd: the purified miscella will be pumped into it.

(6)Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be

discharged to condenser for recycling.

(7)Condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.

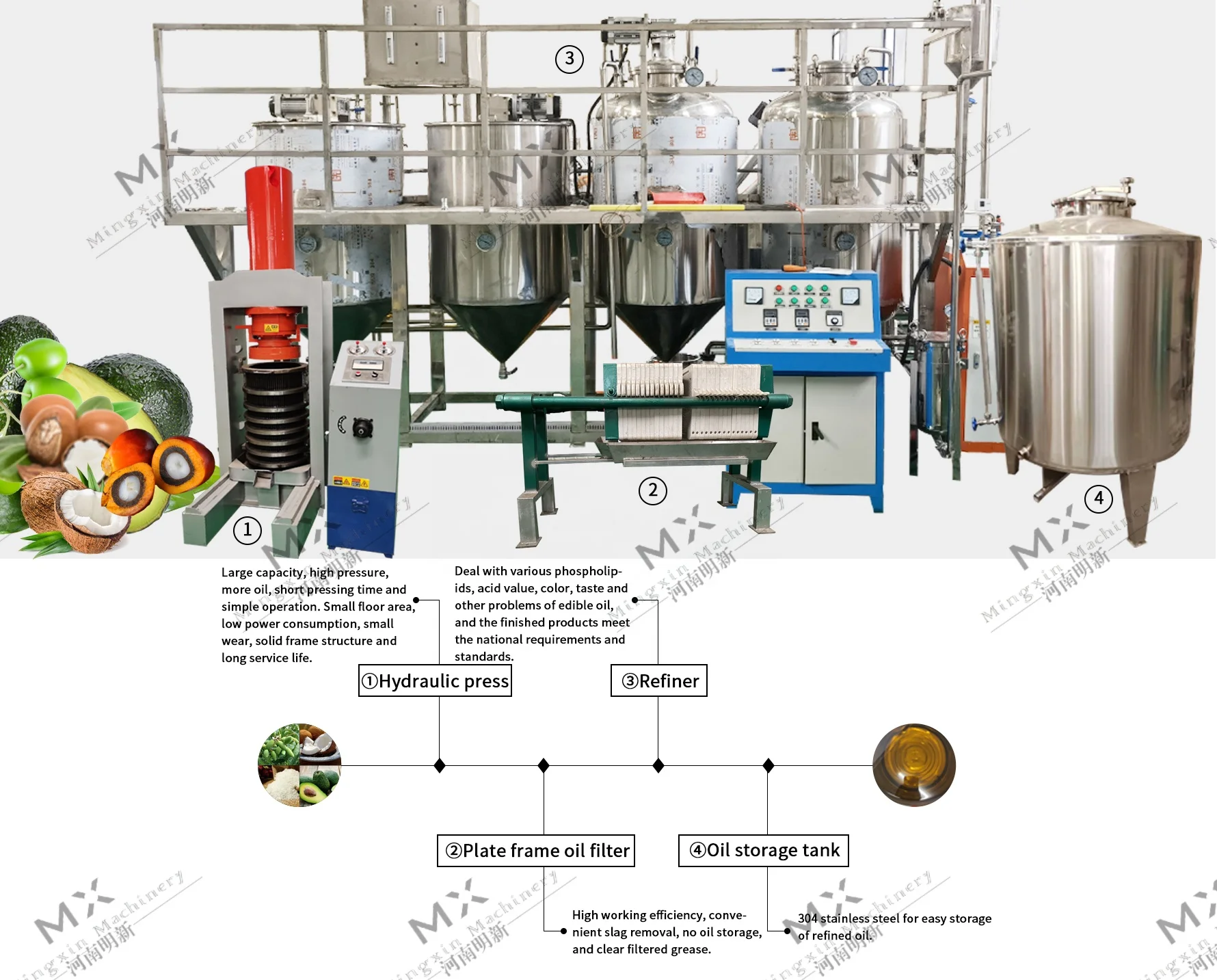

what edible oil processing machines we supply?

Our Sinoder Indutech Machinery Company supply the complete set of Cooking oil production line machinery including sunflower oil production line, palm oil production line, soya bean oil production line, peanut oil production line, cotton seeds oil production line, maize corn germ oil production line, clamelia oil production line, rapeseeds oil production line, canola oil production line, coconut cropra oil production line, shea oil production line, groundnuts oil line, sesame oil production line,black seeds oil production line, jatropha seeds oil production line,moringa seeds oil production line and other vegetables oil processing machines.

Edible oil press machine, which is also called oil expeller, oil extraction machine or oil mill, It can be used for various raw materials, such as soybeans, peanuts, cotton seeds, rape seeds, sesame seeds, sunflower seeds, canola seeds, coconut seeds, tea seeds, palm seeds and jatropha seeds.

We meet the demands of virtually every application in the vegetable oil processing industries. With premium quality oil mill machinery, oil extraction machines and professional oil processing systems & oil refining technologies in the field of vegetable oil extraction and refineries, you can depend on our equipment and expertise to help you hulling, crushing, conditioning, flaking, cooking, extruding, expelling, extracting, degumming, neutralizing,dewaxing/fractionation.

We (our Sinoder Company) supply small scale oil press machines for home or village use, Hydraulic Oil Press Machine for small scale oil factory and home use, large scale production oil screw pressing line and oil refinery lines for commercial production factory use.

Sinoder Brand 6YL Series Small Scale Oil Press Machines (for home or village family workshop use)

Sinoder Brand 6YL Series Small Scale Oil Press Machines Parameters:

Model | 6YL-60 | 6YL-80 | 6YL-100 | 6YL-120 | 6YL-160 | |

Dia. | φ 53mm | φ 81mm | φ 101mm | φ 123mm | φ 160mm | |

Screw speed | 64r/min | 47r/min | 38r/min | 35r/min | 32r/min | |

Motor Power | Motor | 1.5-2.2kw | 5.5kw | 7.5kw | 11kw | 22kw |

Vacuum pump | 0.18kw | 0.55kw | 0.75kw | 1.1kw | 2.2kw | |

Heater | 0.9kw | 2.2kw | 2.2kw | 2.2kw | 0.9kw | |

Capacity | 40-60kg/h | 80-100kg/h | 150-200kg/h | 250-300kg/h | 500-600kg/h | |

Weight | 268kg | 880kg | 1250kg | 1500kg | 1800kg | |

Size (mm) | 1020×720 ×798 | 1500×1200 ×1750 | 2000×1300 ×1850 | 2100×1300 ×1850 | 2300×1300 ×1950 | |

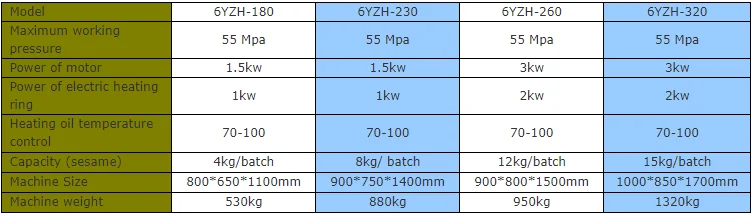

Sinoder Brand 6YZH Series Hydraulic Oil Press Machine for small scale oil factory and home use

Sinoder Brand 6YZH Series Hydraulic Oil Press Machine Parameters:

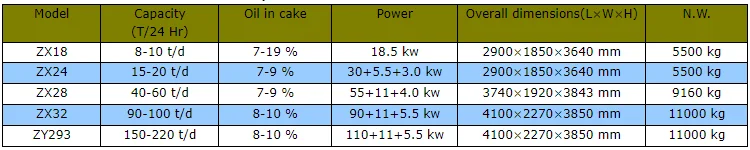

Large scale screw Oil pressing Machine for commercial oil factory use

Sinoder Brand ZX/ZY Series Screw Oil Expeller Machine Parameters:

♦ Cleaning process : Use vibration cleaning sieve and magnetic selector to get better cleaning effect.And This step is mainly to clean the big impurities ,like the stone, big dust , iron etc.

♦ Crushing Process: This Process is mainly to crush the peanut , as the peanut is big ,it is not easy to press .We must crush the peanut to 6-8 pieces,then we need to peel .The rate of peel is about 90%.

♦ Flaking Process : After crush and peel ,we need to flake the crushed sunflower , which make the cell wall of sunflower broken . And we flake the sunflower to 0.55 mm thickness .Then it is useful for the oil extracting..

♦ Cooking Process: After the flaker,we need to cook the flaked sunflower , control the moisture at 5-7% ,the temperature is 110-115degree.

♦ Oil-pressing : After all the pretreatment , pre- press the sunflower , the oil can be extracted about 76% .

♦ Primary Oil Filtering Process: after the oil pressing, the crude oil will be primary filtered and for store to tank or for next process of oil refinery.

Solvent Extraction, as the name suggests is a process to extract the oil from oil bearing materials by means of Solvent, Solvent used being normal Hexane – a petroleum bye product.

The plant is designed to extract oil directly from oil seed containing less than 20% oil like soyabean after flaking or it extracts oils from prepressed or fully pressed cake of seeds containing more than 20% oil like sunflower, peanuts, cotton seed, palm kernel, canola, copra, castor and variety of other materials.

Edible oil refining contains vegetable oil refining, animal oil refining, microbial oil refining. The crude oil refining production line can remove impurity of oil and obtain high quality standard finished refined oil through washed degumming, alkali refining soap removal, mixed proportion, blenching, filtration, physical deacidification and deodorization, crystallization and maturing and including following process:

Decolorizing / Bleaching: Remove color pigments contained in oil

Deodorizing: Remove disagreeable flavor and odors that are naturally present or created during processing under high temperatur

Dewaxing (Optional): Oils like sunflower oil or maize germ oil (corn oil) have waxes present in them. At low temperatures these waxes give a hazy appearance to the oil. So, in extremely cold areas, dewaxing should take into accout when processing these oil seeds.

We supply oil refining machines system with capacity from 1ton per day to 600 tons per day.

Sinoder Indutech Machinery Group is one of professional supplier of industrial machinery & accessories in China. The group has industrial machinery department, equipments accessories department, instrument & sensor department, industrial solution department and marketing service department. The main products cover vegetable oil mill expeller, oil solvent extraction plant, cooking oil refinery plant & fractionation plant & winterization plant, industrial drying machines,fertilizer making machines,coal gasification plant, perlite expansion furnace, industrial crushing machines, mineral processing machines, construction brick machines, biomass energetic machines, environment protection equipment, food oil press milling machines and other mechanical equipment. Our key product include oil mill, oil extraction machine, oil refinery machine, stone crusher,sand maker, stone washing machine, ball mill, flotation cell, rotaty drying machines, biomass burner, coal gasifier, food & oil press machine,oil refinery machine, packaging machine, breeding machines, fertilizer and pellets machine, agricultural machinery and other machines.

Scientific and technological innovation, excellent quality, customer satisfaction is our consistent business principle, service is company's long-term commitment.

Our machinery and technology applied in tens of projects all over the country 28 provinces, autonomous regions, and exported to Russia, north Korea, Indonesia, kazakhstan, kyrgyzstan, Bangladesh, Malaysia, Vietnam, Rwanda, Sudan, Algeria,Hongkong Zone, Japan, America, Canada, Mali, Uganda,Chile,Argentina,Bolivia and other countries, well received by customers at home and abroad. Our proudct well received by customers at home and abroad

1.Pre-sale services:

1) Selecting equipment type;

2) Designing and fabricating the products in accordance with the special requirements of the clients;

3) Training technical personnel for our clients;

4) Providing construction and technology consultations or working out proper construction schemes for those new, special or difficult projects.

2.Services provided during the sale:

Respect our clients; present the clients with ease, relaxation and a surprise; devote ourselves to improve the total value of our clients.

1) Checking products acceptance ahead of delivery;

2) Introducing the service system to our clients.

3. After-sale services:

Improve the added value of our products, and let the clients free from the using troubles:

1) Assisting the clients preparing for the first construction scheme;

2) Installing and testing the equipments;

3) Training the first-line operators on site;

4) Examining the equipment regularly;

5) Taking the initiatives to eliminate the failure(s) rapidly at site;

6) Distributing the guarantee fittings door-to-door;

7) Providing technical exchanging;

8) Providing maintenance for big item

1.Waterproof packing with the international export standard by 20ft, 40ft, 40HQ container.

2. Equipment Fittings, Electric Motor and Power Cabinet will be packed in Wooden Case or Iron Box. Other Equipment will be packed by Color-Stripes Plastic Cloth.

3. Or as per customer's requirements.

For solvent extraction plant ,I need to confirm something before sending you quotation .

1.What raw material do you want to process?

2.What is the required capacity ?

Then, I can recommend suitable model and send you quotation.

Похожие товары

Высококачественный 5-50TPD соевое масло гексан машина для экстракции и рафинирования растворителем растительного пищевого масла

Машина для переработки подсолнечного масла Машины Для Производства арахисового малого бизнеса

Мелкомасштабный завод по переработке пищевого масла машина для переработки подсолнечного сырого пальмового

BTMA-ZX-85 маслопрессовки масломельница для производства канолового масла машина холодного прессования подсолнечника

10-100TPD пальмовый нефтеперерабатывающий завод список оборудования для кухонного нефтеперерабатывающего завода проект по заводской цене на съедобное пальмовое масло

Заводское масло для экстракции пальмы список нефтяных заводов в Малайзии

Высококачественный Масляный Пресс масляная мельница пресс для масла авокадо в Китае распродажа

Новые поступления

Новинки товаров от производителей по оптовым ценам