Профессиональные японские запчасти для самосвала гидравлический подъемник KRM 201

- Категория: >>>

- Поставщик: Liuzhou Shuangji Machinery Co. Ltd.

Сохранить в закладки 1600487474803:

Описание и отзывы

Характеристики

Professional Japanese dump truck parts builder hydraulic hoist KRM 201 for tipper trailer

Hoist Mechanism, Dimensions and Weight

| Length | Width | Height | Min.Closed Length | Weight |

| 1886mm | 590mm | 476mm | 1275mm | 515kg |

Hoist Cylinder Specification

| Working Pressure | Inner Diameter | Stroke | Min.Close Distance | Piston Rod Diameter | Max.Pressure |

| 10.3MPa | 200mm | 878mm | 1211mm | 100mm | 20.6MPa |

Hoist Mounting and Maximum Lifting Capacity

| Recommen ded Truck G.W. | Body Length | Rear Overhang Length | Distance between Load Center and Hinge | Distance between Trunnion and Hinge | Rated Lifting Capacity | Designed Max. Lifting Capacity |

| 25000-32000kg | 6000mm | 1000mm | 2000mm | 2630mm | 15000-30000kg | 50200kg |

Factory Price KRM201 Dump Truck Lift Hydraulic Cylinder Packing Detail:

1. Container order will pack in palte, 45 sets in a 20ft container.

2. LCL order will pack in plywood case.

Factory Price KRM201 Dump Truck Lift Hydraulic Cylinder Manufacturer Process:

Why Choose us:

over 15 years manufacturing experience in hydraulic lifting industry.

these are what makes us walk such far:

1. Competitive price

We are the manufacturer, and have lots of order from domestic and foreign each year, so we can purchase the raw material with much cheaper price which will directly effects the price of the lifting machines.

2. Reliable quality

a. Material used. all the material are pass the quality check before manufacturing.

b. Oil Paint. the oil paint we used meet international standard which looks more bright and smoothly, also not easy to remove or come off.

3. Good service

We have professional engineer team and R&D team. we could provide professional install solution within 24 hours.

4. Keep Innovations

We welcome every recommendation and opinion from you and make progress together with you.

OEM are highly welcome

How do we control our quality:

1. Cylinder products have to pass strict quality control from purchasing materials, processing, assembling ( we passed the certification of ISO/TS 16949:2009)

2. Automated cleaning equipment to ensure the cleanliness of fuel tank assembly.

3. Welding with CO2 arc and automatically girth welding, which can ensure the welding quality of seal parts.

4. Full cylinder inspection, all products need to 100% pass the comprehensive test before delivery out from factory.

Our Advantages:

1. High quality dump hoist with 100% factory test and competitive price.

2. Professional technical service, more than 15 years experience in hydraulic products, we can design as your idea.

3. Strong and standard package.

4. One year warranty with CE& ISO certification.

5. Professional over 10 years experience in international trade and shipment.

6. Customers' brand and packing are acceptable.

Liuzhou Shuangji Machinery is an experienced and professional manufacturer of hydraulic cylinders. With over 12 years' experience in manufacturing, we can produce all kinds of hydraulic cylinders which include KRM series cylinder, telescopic cylinder, small hydraulic cylinder, OEM cylinder, Gear pump, PTO, ect. Our products can be widely used in dump truck, tipper, and trailer for Japanese truck etc.

Single-action hydraulic cylinder is our superstar product, it is recognised around the world for its good performance.

Our company and certification:

OEM are highly welcome:

We are in Exhibition:

Q1:Hydraulic cylinder internal leakage?

A: There are 3 main reasons causing internal leakage :Overload,polishing is not well controlled,bad seal kits. our products all designed to bear the overload power.We have numerical control machine to assure the polish processing .And we use the imported seals to meet customers' demands.

Q2:Does your piston rod get ruptured easily?

A: Hard chrome plating quenched and tempered 45# steel for piston rod to assure sufficient hardness and toughness.

Q3:Is your design reasonable? What about your product safe coefficient?

A:We have R&D team with abundant design experience. We also established production, education, and research cooperation with universities . Rest assured.

Q4:What about the quality feedback of your products?

A: Guarantee the quality from the raw material. We have cold drawing production line and nickel-chrome electroplating production line , so we can produce cold-drawing pipe and hard-chrome pipe used for hydraulic cylinder.

Q5:How about the delivery time?

A: Over 200 sets advanced equipment to meet customer's large demand in short delivery time.Generally ,it's 15-20 days.

Q6:What 's the after-service?

A:If there is any quality issue, please send us photo or video. Our engineer team will give solution within 24 hours.

Our Other Products:

Похожие товары

Чипов 50 шт./лот IRFI640 IRF1640 MOSFET N-CH 200V 9.8A TO220FP IRFI640G

Dcec дизельный вспомогательный двигатель Cummins nt855 дизельный двигатель NTA855-DM NT855-DM 200KW 336KW

Распродажа: свежие апельсины для пупка, сочные медовые апельсины

Низкопрофильная грузовая шина RUIJIDE 295 75 22,5 с DOT Smartway

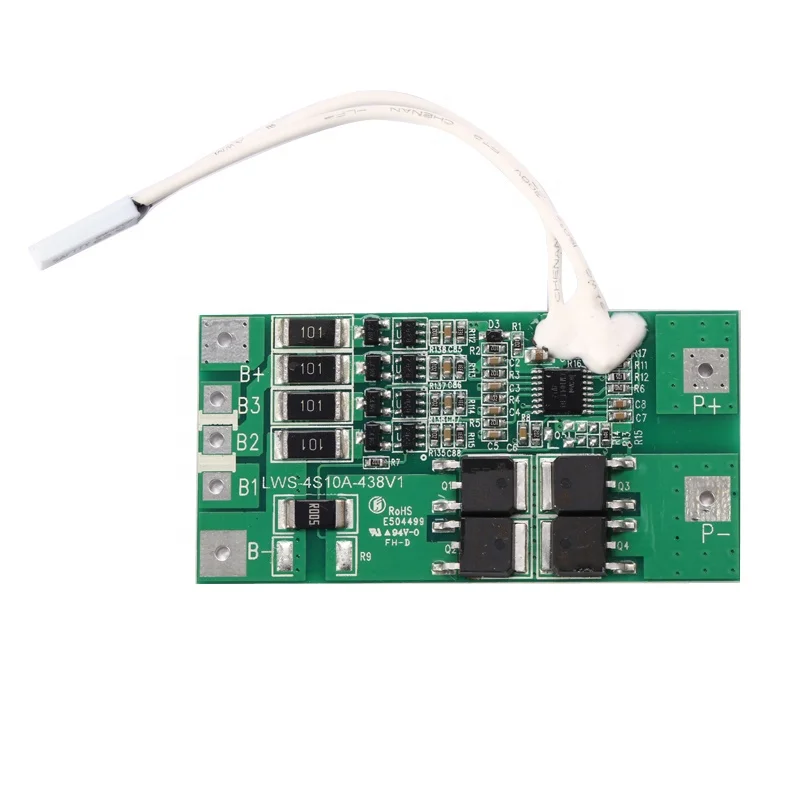

4S8A блок питания печатная плата 3S10A аккумулятор 12,8 В lifepo4 12 В Производитель smart bms

Популярный КУС Bi-Led Aozoom, объектив проектора Angel Eye, фара, Bi-LED объектив проектора, фара

UN SC2E5 5,5x6 мм газоразрядный трубчатый ограничитель с SMD

Новые поступления

Новинки товаров от производителей по оптовым ценам