Штамп с прогрессивным алюминиевым ребристым покрытием для кондиционера испарителя конденсатора и осушителя воздуха

- Категория: >>>

- Поставщик: Wuxi Wondery Industry Equipment Co. Ltd.

Сохранить в закладки 1600488387002:

Описание и отзывы

Характеристики

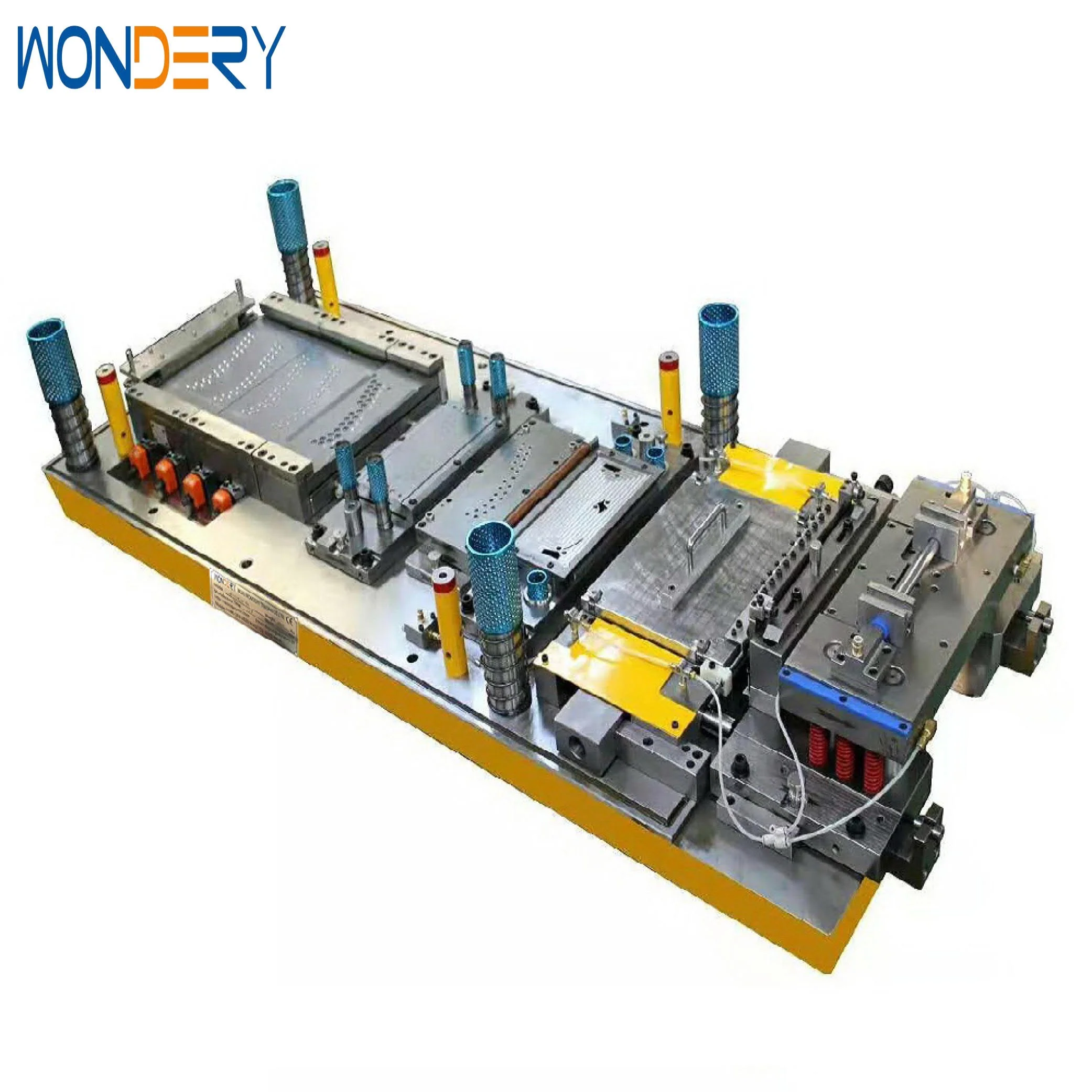

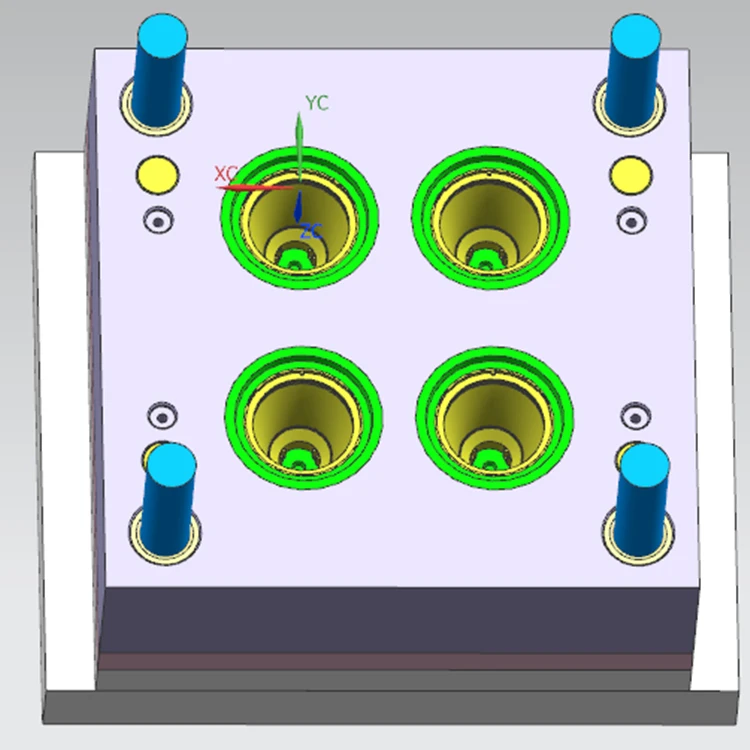

New customized High Speed Making Machine Aluminum fin die Progressive Fin Die

FIN STAMPING DIE GENERAL INFORMATION

The progressive fin die is a professional die working together with high speed fin press machine. It

is also called as metal punch die, or metal stamp die.

This kind of fin die is suitable for household air conditioner, central air conditioner, automobile air conditioner, industrial

heat exchanger, dehumidifier, industrial radiator, etc.

It is suitable for aluminum foil of different grades and thicknesses, and can be customized.

The punching die is easy to maintain and use, and the interchangeability of parts is excellent. All standard parts such as guide post, guide sleeve, spring and screw are imported products.

is also called as metal punch die, or metal stamp die.

This kind of fin die is suitable for household air conditioner, central air conditioner, automobile air conditioner, industrial

heat exchanger, dehumidifier, industrial radiator, etc.

It is suitable for aluminum foil of different grades and thicknesses, and can be customized.

The punching die is easy to maintain and use, and the interchangeability of parts is excellent. All standard parts such as guide post, guide sleeve, spring and screw are imported products.

ITEM | PARAMETERS |

NAME | progressive fin die |

MODEL | CUSTOMIZED |

APPLICATION | household air conditioner, central air conditioner, automobile air conditioner, industrial heat exchanger, dehumidifier, industrial radiator, |

FIN LUBRICANT | high tensile fin lubricant |

FIN SPECIFICATION | customized |

FIN SURFACE SHAPE | corrugated, flat, etc |

REFERENCE UPPER AND LOWER FIN DIES

PROGRESSIVE FIN STAMPING DIE MATERIAL LIST

NO. | Product Name | Material / brand | Heat treatment hardness | Place of Origin |

1 | Pierce male and female die | HAP40 | HRC 62-64 | Japan |

2 | Slitting upper and lower blade | HAP40 | HRC 62-64 | Japan |

3 | Trimming up and down blade | HAP40 | HRC 62-64 | Japan |

4 | Cross cutting upper and lower blade | HAP40 | HRC 62-64 | Japan |

5 | Drawing discharge plate | NAK80 | HRC 40-42 | Japan |

6 | Drawing female die formwork | NAK80 | HRC 40-42 | Japan |

7 | Subdie template | NAK80 | HRC 40-42 | Japan |

8 | Cross cutter fixing seat | NAK80 | HRC 40-42 | Japan |

9 | Drawing male and female die | SKD11 | HRC 62-64 | Japan |

10 | Flanging male and female die | SKD11 | HRC 62-64 | Japan |

11 | Sub die frame | PDS 5 | Pre hardened steel | Japan |

12 | Male and female die fixing plate | PDS 5 | Pre hardened steel | Japan |

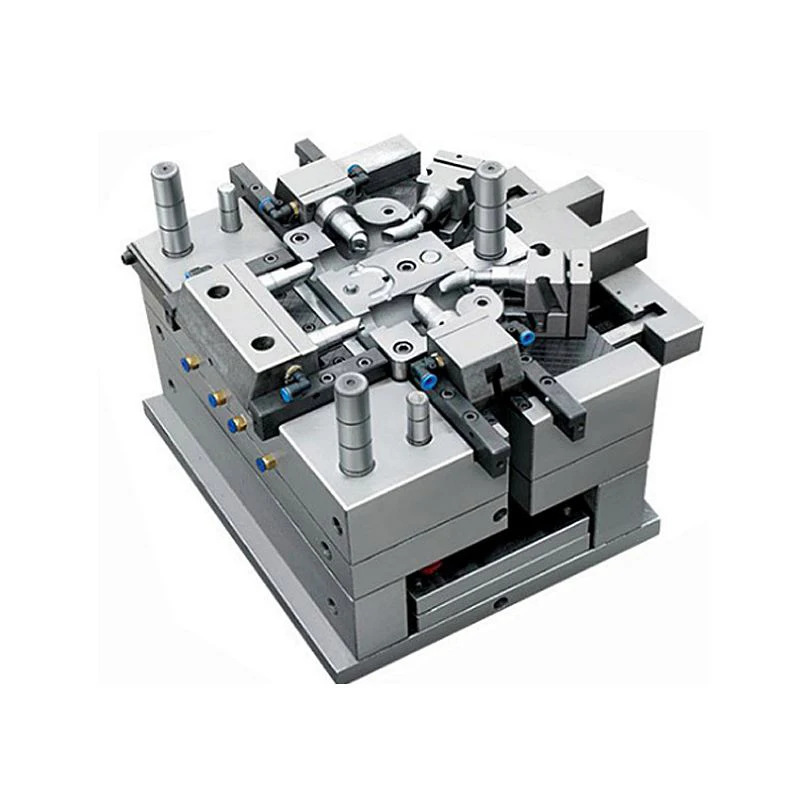

Basic Structure of Metal Punch Die

working process of Fin

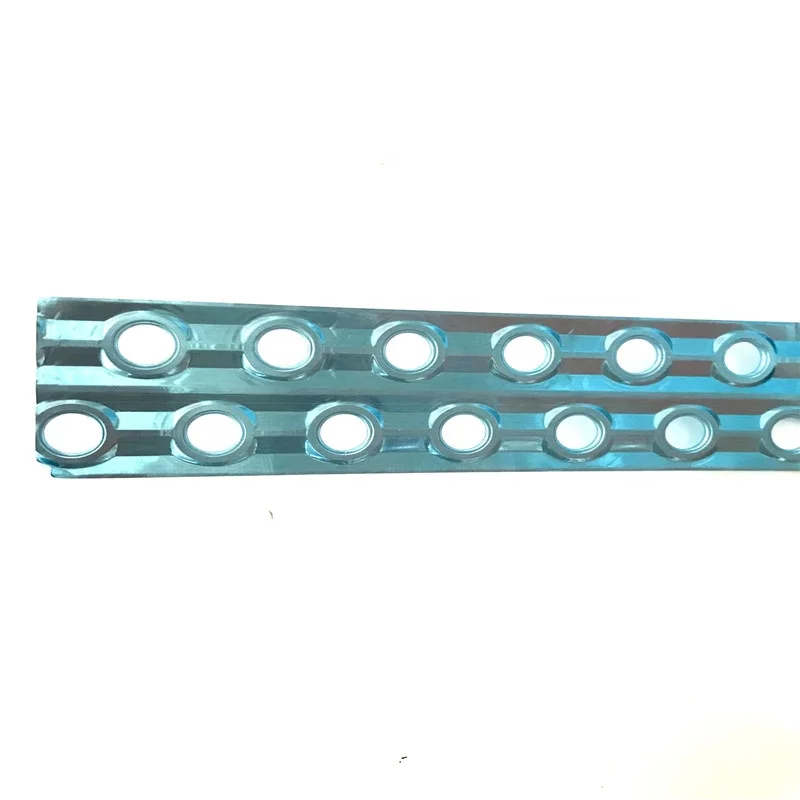

Drawing → pierce drawing → flanging → trimming→ longitudinal cutting → feeding → linear cross cutting.

1. Drawing: the drawing die is completed by several steps. The height is adjusted by adjusting the regulator on the die, and each drawing can be adjusted separately to complete V-wave forming in the last drawing step.

2. Piercing and stretching: when the sliding block of the press machine is lowered, the piercing shall be completed first, the sliding block shall continue to descend, and then the stretching shall be completed.

Drawing → pierce drawing → flanging → trimming→ longitudinal cutting → feeding → linear cross cutting.

1. Drawing: the drawing die is completed by several steps. The height is adjusted by adjusting the regulator on the die, and each drawing can be adjusted separately to complete V-wave forming in the last drawing step.

2. Piercing and stretching: when the sliding block of the press machine is lowered, the piercing shall be completed first, the sliding block shall continue to descend, and then the stretching shall be completed.

2.1 The piercing die adopts the structure of independent guide post and guide sleeve to ensure the forming accuracy and service life, which is convenient for maintenance and replacement of piercing male and female die.

2.2 A sealing device shall be added to the upper formwork of piercing strethcing die to prevent air leakage and affect waste chip removal.

2.3 The base plate that is easy to be replaced shall be added to the piercing lower die to prevent pits in the large formwork after long-term production and filling the service life of the formwork under separate protection. When the female die bursts, the base plate is damaged or the double eye ring of the fin is unclear, simply replace the base plate.

2.4 The material downfall hole of the lower formwork shall not be chamfered to ensure the smooth discharge of waste materials.

2.5 The size and concentricity of piercing male and female die shall be controlled within 0.002mm, so that the parts have excellent interchangeability.

2.6 The piercing male die is provided with air holes in the horizontal and vertical directions to ensure lubrication and cleaning. At the same time, it adopts automatic oil supply mist device to ensure forced chip removal.

2.7 The piercing and flanging female die sleeve is embedded with a push sleeve to prevent the waste from being stuck in the flanging sleeve during stretching mandatory pop-up.

2.8 The piercing female die adopts the clamping table structure, and the integral pressing plate is fixed to prevent it from running up, so as to avoid damaging the whole die when the female die is blocked and pulled out.

3 Flanging: the flanging height can be adjusted arbitrarily through the regulator on the die.

The flange height difference of fins in the same row is ≤ 0.02mm, and the flange height difference of any two rows of fins is ≤ 0.03mm

4 Trimming : the trimming adopts an independent structure to cut off the excess edge materials, and has a special method to prevent the waste from jumping up. The cutting knife is designed into a double-sided knife edge structure to maximize the service life and efficiency of the knife edge.

5 Longitudinal cutting: the upper and lower blades are used to cut any number of rows of fins. The longitudinal cutting upper blade adopts a fast switching structure the upper template is designed with 5 rows (1-5) of different numbers from left to right to realize the rapid adjustment of the number of fin rows. The upper and lower blades are interchangeable, and ensure that the gap between the upper and lower blades is reasonable, and there is no interface edge in the strip.

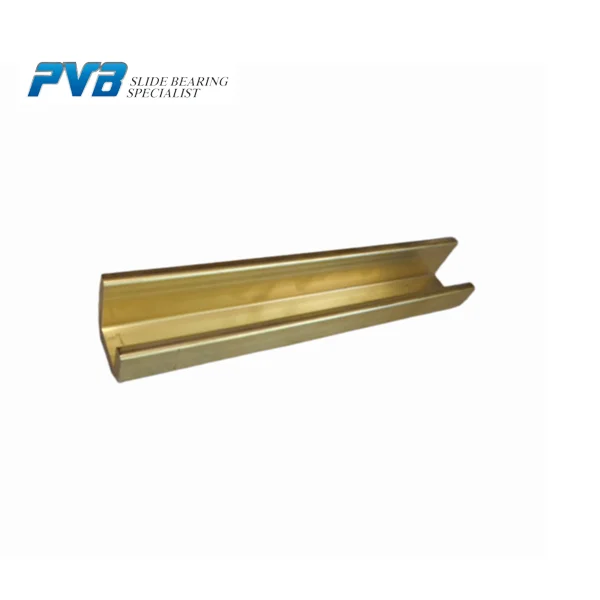

6 Feeding: our feeding form is the best pulling type at present, which is inserted into the mold through the tiny gripper on the mold pullING the material in the formed hole forward (using the connecting rod on the die and press machine). Feeding finger is made of materials SKD11, an oil-free self-lubricating sleeve is added between the feeding finger and the fixed plate to avoid inaccurate positioning after long-term pulling movement.

7 Straight line cross cutting: the punching in the length direction of the fin is realized through the cylinder, solenoid valve and electrical control circuit on the punching machine cut.

The oil-free lubrication method shall be adopted for the transverse cutting part, and the oil-free lubrication contact surface shall be increased as much as possible. Each cross cutting front is provided with an independent adjusting mechanism for adjusting the curvature of the fins. It is more conducive to the adjustment of the air suction and material receiving system and the completion of more reliable operation high speed blanking and more flat fins are produced at the same time, which is conducive to the production of the next process. Crosscutting can move at half a step distance, because the cross cutting die is positioned accurately and the front and rear position adjustment is simple, there will be no cutting hole or touching hole phenomenon.

2.2 A sealing device shall be added to the upper formwork of piercing strethcing die to prevent air leakage and affect waste chip removal.

2.3 The base plate that is easy to be replaced shall be added to the piercing lower die to prevent pits in the large formwork after long-term production and filling the service life of the formwork under separate protection. When the female die bursts, the base plate is damaged or the double eye ring of the fin is unclear, simply replace the base plate.

2.4 The material downfall hole of the lower formwork shall not be chamfered to ensure the smooth discharge of waste materials.

2.5 The size and concentricity of piercing male and female die shall be controlled within 0.002mm, so that the parts have excellent interchangeability.

2.6 The piercing male die is provided with air holes in the horizontal and vertical directions to ensure lubrication and cleaning. At the same time, it adopts automatic oil supply mist device to ensure forced chip removal.

2.7 The piercing and flanging female die sleeve is embedded with a push sleeve to prevent the waste from being stuck in the flanging sleeve during stretching mandatory pop-up.

2.8 The piercing female die adopts the clamping table structure, and the integral pressing plate is fixed to prevent it from running up, so as to avoid damaging the whole die when the female die is blocked and pulled out.

3 Flanging: the flanging height can be adjusted arbitrarily through the regulator on the die.

The flange height difference of fins in the same row is ≤ 0.02mm, and the flange height difference of any two rows of fins is ≤ 0.03mm

4 Trimming : the trimming adopts an independent structure to cut off the excess edge materials, and has a special method to prevent the waste from jumping up. The cutting knife is designed into a double-sided knife edge structure to maximize the service life and efficiency of the knife edge.

5 Longitudinal cutting: the upper and lower blades are used to cut any number of rows of fins. The longitudinal cutting upper blade adopts a fast switching structure the upper template is designed with 5 rows (1-5) of different numbers from left to right to realize the rapid adjustment of the number of fin rows. The upper and lower blades are interchangeable, and ensure that the gap between the upper and lower blades is reasonable, and there is no interface edge in the strip.

6 Feeding: our feeding form is the best pulling type at present, which is inserted into the mold through the tiny gripper on the mold pullING the material in the formed hole forward (using the connecting rod on the die and press machine). Feeding finger is made of materials SKD11, an oil-free self-lubricating sleeve is added between the feeding finger and the fixed plate to avoid inaccurate positioning after long-term pulling movement.

7 Straight line cross cutting: the punching in the length direction of the fin is realized through the cylinder, solenoid valve and electrical control circuit on the punching machine cut.

The oil-free lubrication method shall be adopted for the transverse cutting part, and the oil-free lubrication contact surface shall be increased as much as possible. Each cross cutting front is provided with an independent adjusting mechanism for adjusting the curvature of the fins. It is more conducive to the adjustment of the air suction and material receiving system and the completion of more reliable operation high speed blanking and more flat fins are produced at the same time, which is conducive to the production of the next process. Crosscutting can move at half a step distance, because the cross cutting die is positioned accurately and the front and rear position adjustment is simple, there will be no cutting hole or touching hole phenomenon.

Progressive Fin Stamping Punching Die: Dia13.1mm*35mm*35mm

Texture of Material | Material thickness | Material width |

8011-h22 optical foil and hydrophilic aluminum foil Elongation > 20% | 0.18mm-0.28mm | 295mm±1mm |

Fin hole diameter | Hole spacing line direction | Hole spacing in row direction | Longitudinal notch shape |

Φ 13.1 ± 0.03mm | 35mm ± 0.03mm | 35mm ± 0.03mm | linear |

No. | Material thickness | Height range (adjustable) | Remarks |

1 | 0.18mm | 5mm | |

2 | 0.22mm | 7mm | |

3 | 0.28mm | 9.5mm |

Wuxi Wondery Industry Equipment Co., Ltd. enjoys a very good reputation and credit in related fields. We have developed high quality progressive fin dies with long life and high quality. We have a professional R&D team, imported high quality machining center, wiring cutting machines, drilling machines,etc. We can control the overall quality of the HVAC equipment and fin dies from design to manufacture, and the lifelong after sales service. We have more than 20 years experience in this HVAC equipment field. We are a professional supplier of full HVAC equipment production line such as fin press machine, progressive fin die, vertical tube expanding machine, hairpin bender, return bending machine, heat exchanger bending machine, etc.

1. What is the power supply of the heat exchanger making machines?

The power supply of heat exchanger making machines is to be decided by the customer's side. We are able to adjust the power supply (volt, and phase) through a transformer or of the customer's voltage directly so that the melting furnace is ready for use at the end user's site.

2. What information should the customer provide to get an accurate quotation from us?

The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc.

3. What is the payment term?

The payment term is 40% down payment, and 60% before delivery (T/T mode).

4. What is the delivery time?

The delivery time of the machine is 30-60 days after receipt of down payment.

Похожие товары

Гипсовый потолочный декоративный Стекловолоконный светильник форма для изготовления силиконовых форм лампы медальон панельный молдинг продажи

5T8365 446-1524 бронзовая износостойкая лента 5T8366

Пластиковая литьевая форма ABS PP PE Нейлон POM бытовая продукция дизайн и разработка производителя

330,64 ₽ - 440,85 ₽

Быстрые формы для бритвы

40 667,97 ₽ - 54 995,44 ₽

Формовочная машина форма для светодиодных ламп Отличная от производителя различные формы литья под давлением

Форма для детали электроники транспортного средства с 8 картриджами форма автомобильных электронных компонентов из нейлона и стекловолокна

2 435 669,73 ₽ - 2 479 754,25 ₽

Пластиковые литьевые формы для электронных компонентов

11,03 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $