Сельскохозяйственная цилиндрическая сушилка для кукурузы барабанная Роторная

- Категория: Chemical & Pharmaceutical Machinery >>>

- Поставщик: Gongyi Derui Machinery Co. Ltd.

Сохранить в закладки 1600490042323:

Описание и отзывы

Характеристики

Three Drum Rotary Dryer For Grain

The three-cylinder dryer is a high-efficiency and energy-saving product improved on the basis of the single-cylinder tumble dryer in our factory according to market needs. After the application of many enterprises and many industries, good drying effect has been achieved. The three-cylinder dryer improves the internal structure of the single-cylinder tumble dryer, increases the pre-drying design of the wet material before entering the machine and extends the drying time of the wet material in the machine, and installs sealing, heat preservation and reasonable supporting measures. So compared with the original single-cylinder tumble dryer, the production capacity of the three-cylinder dryer is increased by 50-80%, and the evaporation strength per unit volume can reach 120-180kg/m3, and the standard coal consumption is only 6-8kg/t.

With advanced technology, reasonable operating parameters, simple and feasible operation, it can be used in slag, clay, coal, iron powder, slag powder and other mixed materials, also widely used in dry-mixed mortar, yellow sand, etc. of the construction industry, as well as chemical, casting, etc. industry.

In addition, fuel burners, combustion chambers or supporting elevators, belt conveyors, metering feeders, cyclones, pulse dust collectors and spray towers can be designed according to user needs.

1. The three cylinders is designed to be self-insulating, to reduce heat loss;

2. Optimized design of the guide and lifting plate structure to ensure the dispersion of materials;

3. The special thermal design concept eliminates the heat loss of the wind tunnel, and the heat energy utilization rate is significantly improved;

4. Increase the heat exchange area and fully improve the evaporation intensity per unit volume;

5. The thermal efficiency is increased by more than 35%, and energy saving is more than doubled;

6. The equipment area is reduced, and the equipment basic investment is reduced;

7. High efficiency, energy saving, environmental protection, in line with the needs of environmental protection development.

The material enters the inner cylinder from the feeding device to achieve downstream drying. The material is continuously picked up and scattered under the lifting plate of the inner cylinder to achieve heat exchange in a spiral manner, and the material moves to the other end of the inner cylinder and drops the middle cylinder for counter-current drying. The material is continuously raised in the middle cylinder, showing a two-step forward and one-step backward moving mode. The material in the middle cylinder not only fully absorbs the heat emitted by the inner tube body, but also absorbs the middle cylinder. It also prolongs the drying time, and the material reaches a dry state here. The material travels to the other end of the middle cylinder and falls into the outer cylinder. The material travels in the outer tube in a rectangular multi-loop manner to achieve the drying effect and quickly discharges out of the dryer under the action of hot airflow. The wet material that does not achieve the drying effect cannot be fast due to its own weight. As it progresses, the materials are fully dried in the rectangular lifting plate, thereby achieving the drying effect and completing the drying process.

1. Pre-sale support

1) We offer the best solution according to client’s requirement in time.

2) We accept and respect client’s creative idea. We will try our best to integrate client’s idea into the machine and take our years of experience into consideration.

3) We could offer our technical design before the purchase order.

2. After-sale service

1) Our skilled technicians are available for on-site installation, commissioning & training on request.

2) Dimensional drawings together with service requirements will be provided prior to delivery of the equipment.

3) An adequate inventory of spare parts and efficient service personnel are available for emergency case.

4) Our guarantee period is 24 months. Within the guarantee period the broken parts (excluding quick-wear parts)

5) Other after-sale service terms are negotiable.

Our Company Philosophy

- Best Quality for Market

- Perfect Service for Clients

- Scientific Management for Benefits

- Good Credit for Development

Gongyi Derui Machinery Co., LTD entered the mechanical industry from the beginning of the 1980’s, earlier than most factories. With the company philosophy these years, our products are sold to many customers from home and abroad, popular in India, Russia, Kazakhstan, Africa, South America, Mid-East, Southeast Asia, and almost 30 countries and areas. And it is our honor to make a contribution of to the development of these countries.

Growth is only a process, and the brilliance is the new beginning. In order to respond positively to the good policy of The Belt and Road, we will, as always, provide higher and higher quality products and service, to win more and more acclamation and respect for Chinese national industry. Review ourselves with serious attitude, and win the trust with excellent quality. We sincerely hope to take win-win cooperation with entrepreneurs and companies all over the world, to develop the market together.

Похожие товары

Горячая Распродажа промышленная линия по производству бутылочек сиропа для орального наполнения

3D смеситель химических порошков смешивающее оборудование

Небольшая промышленная сушильная машина вращающаяся сушилка с тремя барабанами

5000 кг/ч автоматический аморфофаллус коньяк стиральная пилинг линии сушки porang технологическая линия Белый чипсы барабан сушилки

Высокая производительность Тарельчатая центрифуга для автомобиля перекачивания отработанного

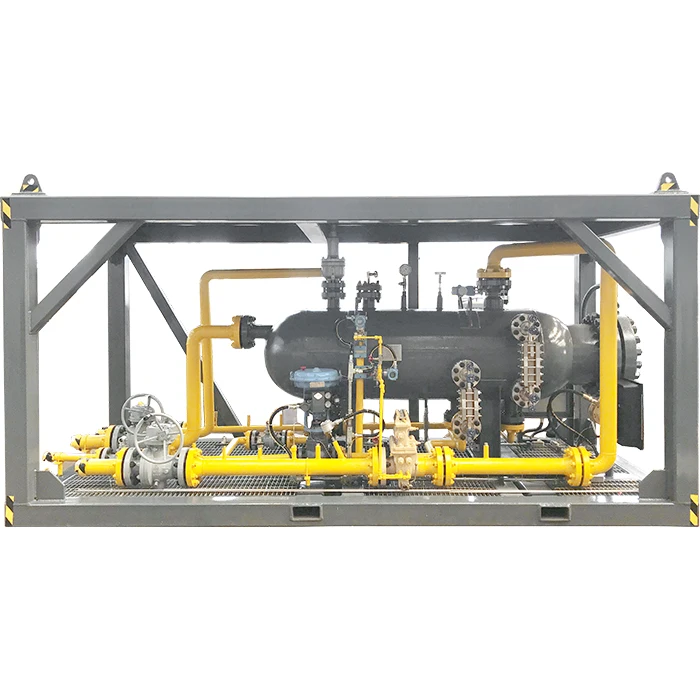

Многоступенчатый сепаратор для испытания скважин/трехфазный гравитационный сепаратор/сепаратор

Многофункциональная машина для извлечения эфирных масел листьев лаванды эвкалипта куркумы оборудование дистилляции эфирного

Новые поступления

Новинки товаров от производителей по оптовым ценам