3D печать SLS/SLA литье смолы Па/ПП/ПК/АБС смола фотополимер Смола ЖК 3D печать служба для футбольного шлема

- Категория: >>>

- Поставщик: Dongguan Linghang 3d Prototype Co. Ltd.

Сохранить в закладки 1600514211188:

Описание и отзывы

Характеристики

Products Description

Helmet 3d printing

There are two ways of producing helmet with a 3D printer. You can either use a direct or indirect production process. Direct refers to the creation of an object straight from the 3D design while indirect manufacturing means that the object (pattern) that is 3D printed eventually is used to create a mold for investment casting.

How Does 3D Printing Work?

It all starts with a 3D model. You can opt to create one from the ground up or download it from a 3D library.

3D Software

There are many different software tools available. From industrial grade to open source. We’ve created an overview on our 3D software page.

We often recommend beginners to start with Tinkercad. Tinkercad is free and works in your browser, you don’t have to install it on your computer. Tinkercad offers beginner lessons and has a built-in feature to export your model as a printable file e.g .STL or .OBJ.

Now that you have a printable file, the next step is to prepare it for your 3D printer. This is called slicing.

Slicing: From printable file to 3D Printer

Slicing basically means slicing up a 3D model into hundreds or thousands of layers and is done with slicing software.

When your file is sliced, it’s ready for your 3D printer. Feeding the file to your printer can be done via USB, SD or Wi-Fi. Your sliced file is now ready to be 3D printed layer by layer.

3D Printing Industry

Adoption of 3D printing has reached critical mass as those who have yet to integrate additive manufacturing somewhere in their supply chain are now part of an ever-shrinking minority. Where 3D printing was only suitable for prototyping and one-off manufacturing in the early stages, it is now rapidly transforming into a production technology.

Most of the current demand for 3D printing is industrial in nature. Acumen Research and Consulting forecasts the global 3D printing market to reach $41 billion by 2026.

As it evolves, 3D printing technology is destined to transform almost every major industry and change the way we live, work, and play in the future.

Examples of 3D Printing

3D printing encompasses many forms of technologies and materials as 3D printing is being used in almost all industries you could think of. It’s important to see it as a cluster of diverse industries with a myriad of different applications.

A few examples:

– consumer products (eyewear, footwear, design, furniture)

– industrial products (manufacturing tools, prototypes, functional end-use parts)

– dental products

– prosthetics

– architectural scale models & maquettes

– reconstructing fossils

– replicating ancient artefacts

– reconstructing evidence in forensic pathology

– movie props

Rapid Prototyping & Rapid Manufacturing

Companies have used 3D printers in their design process to create prototypes since the late seventies. Using 3D printers for these purposes is called rapid prototyping.

Why use 3D Printers for Rapid Prototyping?

In short: it’s fast and relatively cheap. From idea, to 3D model to holding a prototype in your hands is a matter of days instead of weeks. Iterations are easier and cheaper to make and you don’t need expensive molds or tools.

Besides rapid prototyping, 3D printing is also used for rapid manufacturing. Rapid manufacturing is a new method of manufacturing where businesses use 3D printers for short run / small batch custom manufacturing.

Types of 3D printing Technologies and Processes

The American Society for Testing and Materials (ASTM),developed a set of standards that classify additive manufacturing processes into 7 categories.

3D Software

There are many different software tools available. From industrial grade to open source. We’ve created an overview on our 3D software page.

We often recommend beginners to start with Tinkercad. Tinkercad is free and works in your browser, you don’t have to install it on your computer. Tinkercad offers beginner lessons and has a built-in feature to export your model as a printable file e.g .STL or .OBJ.

Now that you have a printable file, the next step is to prepare it for your 3D printer. This is called slicing.

Slicing: From printable file to 3D Printer

Slicing basically means slicing up a 3D model into hundreds or thousands of layers and is done with slicing software.

When your file is sliced, it’s ready for your 3D printer. Feeding the file to your printer can be done via USB, SD or Wi-Fi. Your sliced file is now ready to be 3D printed layer by layer.

3D Printing Industry

Adoption of 3D printing has reached critical mass as those who have yet to integrate additive manufacturing somewhere in their supply chain are now part of an ever-shrinking minority. Where 3D printing was only suitable for prototyping and one-off manufacturing in the early stages, it is now rapidly transforming into a production technology.

Most of the current demand for 3D printing is industrial in nature. Acumen Research and Consulting forecasts the global 3D printing market to reach $41 billion by 2026.

As it evolves, 3D printing technology is destined to transform almost every major industry and change the way we live, work, and play in the future.

Examples of 3D Printing

3D printing encompasses many forms of technologies and materials as 3D printing is being used in almost all industries you could think of. It’s important to see it as a cluster of diverse industries with a myriad of different applications.

A few examples:

– consumer products (eyewear, footwear, design, furniture)

– industrial products (manufacturing tools, prototypes, functional end-use parts)

– dental products

– prosthetics

– architectural scale models & maquettes

– reconstructing fossils

– replicating ancient artefacts

– reconstructing evidence in forensic pathology

– movie props

Rapid Prototyping & Rapid Manufacturing

Companies have used 3D printers in their design process to create prototypes since the late seventies. Using 3D printers for these purposes is called rapid prototyping.

Why use 3D Printers for Rapid Prototyping?

In short: it’s fast and relatively cheap. From idea, to 3D model to holding a prototype in your hands is a matter of days instead of weeks. Iterations are easier and cheaper to make and you don’t need expensive molds or tools.

Besides rapid prototyping, 3D printing is also used for rapid manufacturing. Rapid manufacturing is a new method of manufacturing where businesses use 3D printers for short run / small batch custom manufacturing.

Types of 3D printing Technologies and Processes

The American Society for Testing and Materials (ASTM),developed a set of standards that classify additive manufacturing processes into 7 categories.

About the Material:

Easier to use - 3D Printer resin is easy to use, it does not require a very dry environment or special additive to print and burn well, and this castable 405nm standard photopolymer resin has good plate adhesion.Both new user and experienced users can easily print the model.

Easier to Burn - The castable 3D printer resin material contains 85% wax, so it is easier to burn than manynon-wax based casting resins. This Casting rapid resin is very suitable to be used in the production of small metal parts, which can fully demonstrate the core of the part.

High Resolution - Cast 3D printer resin uses a unique and beautiful Yellow color, and the printed model has a high resolution and smooth surface. Its high resolution allows the model to be printed with precise details, which will make your model look great.

Easy to Print - Casting 3D printing resin can print quickly and has high resolution, is easy to print.This Cast LCD UV-Curing resin is very easy to use and dye, and is a castable resin for jewelers and small metal parts.

Wide Applications - was developed as an affordable castable 3D printer resin by jewelers for making rings and pendant, by engineers for small metal functional parts and by dentist. This Cast 3d printing resin can be used in most LCD 3D printers services.

Details Images

Company Profile

Our Company

Dongguan Linghang 3D Prototype Co.,Ltd. is a professional manufacturer specialized in rapid prototyping, 3D printing, model making and model design. Our rapid prototyping services include: CNC & SLA & SLS rapid prototyping; vacuum casting for low-volume production, production design and development; 3D printing as well as high precision machining. Products of Linghang related to household appliance, automobile, sculpture,medical device, digital product, electronics, appliances, auto parts, toys, and many other industries. The company is located in Changan Town, Dongguan, founded in 2018. After 4 years'

development, the factory has a construction area of 20,000 square meters and has 500 self-owned printing equipment. Our equipment

have more than 100 SLA printers, nylon printers, metal printers, red wax printers,CNC machining center, automatic lathe, surface

grinding machine, meter lathe, CNC lathe, milling machine, plastic injection machine and stamping machine etc. Also we have

successfully established a professional team with superb technique, excellent quality, and enthusiastic service. All these helped

us receive numerous reputations from home and abroad.

have more than 100 SLA printers, nylon printers, metal printers, red wax printers,CNC machining center, automatic lathe, surface

grinding machine, meter lathe, CNC lathe, milling machine, plastic injection machine and stamping machine etc. Also we have

successfully established a professional team with superb technique, excellent quality, and enthusiastic service. All these helped

us receive numerous reputations from home and abroad.

Our teams

We have a strong R&D and design team, they are a group of lively, lovely and passionate young people, skilled technicians and operators, and professional quality control personnel to ensure the quality of our product development and production. The best support for customers, sincerely look forward to your trust and cooperation, come and contact us!

Why Choose Us

3D Printing line

FAQ

FAQ

1.How can I customize my products?

Attach your drawings with details(Suface treatment,material,quantity and special requirements etc).

2.How long can I get the quaotation?

We will give you the quotation within 24 hours(Considering the time difference).

3.How can I get a sample for testing?

We will offer free or charged samples depends on the products.

4.How long will you produce the parts?

Normally two weeks,we will arrange the produce schedule depends on the quantity and the delivery.

5.What's your payment terms?

We accept Western Union/ T/T/Trade Assrance /Paypal

6.How about the transportation?

Samples by air (if not too heavy),otherwise by sea or air.

7.What if the products we received are not good?

contact us without hesitation,our special after-sales service will take the responsibility

Attach your drawings with details(Suface treatment,material,quantity and special requirements etc).

2.How long can I get the quaotation?

We will give you the quotation within 24 hours(Considering the time difference).

3.How can I get a sample for testing?

We will offer free or charged samples depends on the products.

4.How long will you produce the parts?

Normally two weeks,we will arrange the produce schedule depends on the quantity and the delivery.

5.What's your payment terms?

We accept Western Union/ T/T/Trade Assrance /Paypal

6.How about the transportation?

Samples by air (if not too heavy),otherwise by sea or air.

7.What if the products we received are not good?

contact us without hesitation,our special after-sales service will take the responsibility

Похожие товары

Кольцо шестерни высокой точности подгонянное согласно чертежам

29 536,22 ₽ - 30 630,16 ₽

Металлический парковочный знак из нержавеющей стали

Поршень дозирующего насоса с износостойкой керамическим покрытием

На заказ Шестигранная головка из углеродистой стали класса 8,8 высокопрочные черные шестигранные болты сине-белые оцинкованные стальные полнорезьбовые шестигранные болты boltGB5783

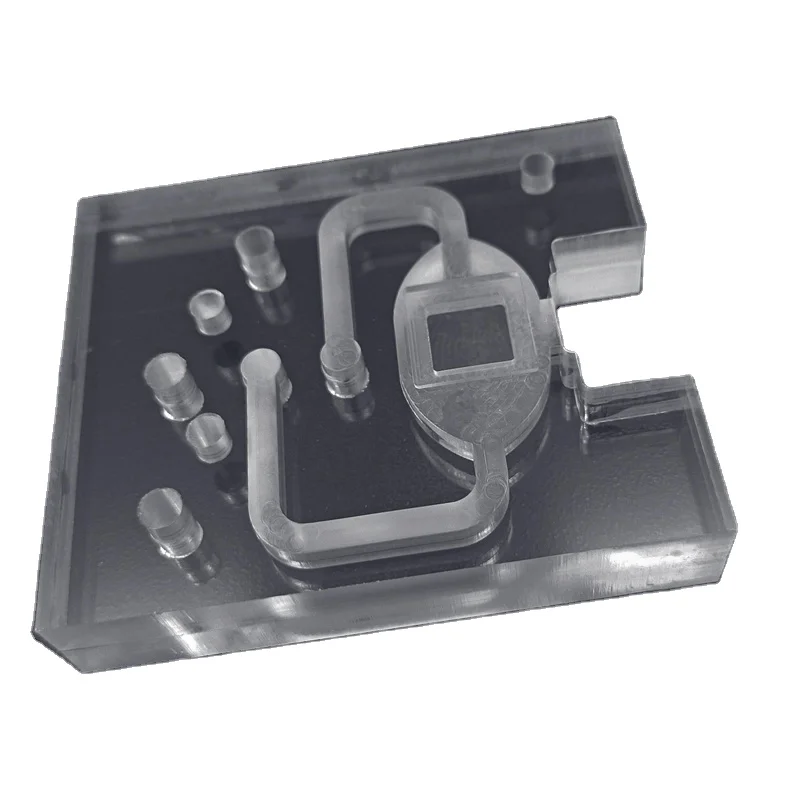

Индивидуальные пластиковые формы для микрофлюидных капельных чипов

3 063,02 ₽ - 3 500,59 ₽

Запасные части для станка Smt, фотокамера SONY E1100 CCD, фотосессия 1-418-772-12

Запасные части для станка Smt SONY E1100 CCD источник питания для камеры IK-54XSL 8-327-081-03

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $