Горячая Распродажа машина для резки ламинированного стекла YINRUI по заводской цене

- Категория: >>>

- Поставщик: Dongguan Yinrui Precision Machinery Co. Ltd.Dongguan Ltd.

Сохранить в закладки 1600519398769:

Описание и отзывы

Характеристики

This machine was research and development in our company. IT`s easy to use ,highly adaptab.

1:Structure of machine

Frame was made with international square steel tube and box iron by welding.The key position had been annealing treatment and gantry milling. So the frame has high stability and strength.

Two-part construction to assemble the machine. The first part is the artificial auxiliary feeding and transmission part, equipped with automated positioning system. The second paragraph contains the upper and lower knife cutting system, the cutting film system, the heating system, and the auxiliary discharge system.

2:Machine Parameters

1.Size of machine:4800*3800*1300mm

2.Weight:about 3000KG

3.Processing range of glass size:400*400mm 3700*2500mm

4.Processing range of glass thickness:3+X+3mm 8+X+8mm

5.Cutting speed: cutting twice in one minute

6.Temperature and time of heating: Adjust by operater

7.Pressure of pushing and breaking: Adjust by operater

3:Machine configuration,(can be custmized)

1.Motor:Delta SERVO MOTOR

2.Drive: Delta

3.Plc and touch screen: Delta

4.Electrical elements: CHINT

5.Program: Self-Design

6.Heatting tube: China

7.Timing belts and wheels: China

8.Air cylinder and knife: Self-Design

9. Knife wheels: imported from Japan

10.Draught fan: China

11.Transmission shaft: China

12.Felt:imported

13.Proportional control valve: SMC from Japan

4:Technical process

Man-machine interface HMI setting system parameters such as glass width, length, under knife pressure, etc.

mechanical placement of glass into the synchronous belt area of the cutting table

Automatic transmission and positioning of glass according to the cut size of input(There's a location system)

Knife head at zero

Pneumatic lower knife, upper and lower knife wheel cut(There's an automatic injection system)

Cut and lift

The upper press starts the press, and the lower surface glass breaks open

Under the top rod up the glass, the upper surface of the glass break open

Heat bar, start heating

The vacuum suction cup absorbs the glass on both sides of the tangent line and pulls the cutting seam apart

Cutting film(PVB or EVA)

The cutting action is complete and the entire artifact is transferred to the next segment tangent position(If you need to turn around and cut, you need to do it manually)

Whole cutting is complete

Manually move the processed glass to the lower slide flip bracket with the air float assembly.

5:advantage

1. Can automatically set the cutting length width, labor saving.

2. Compare the previous ones,faster, more accurate.

Похожие товары

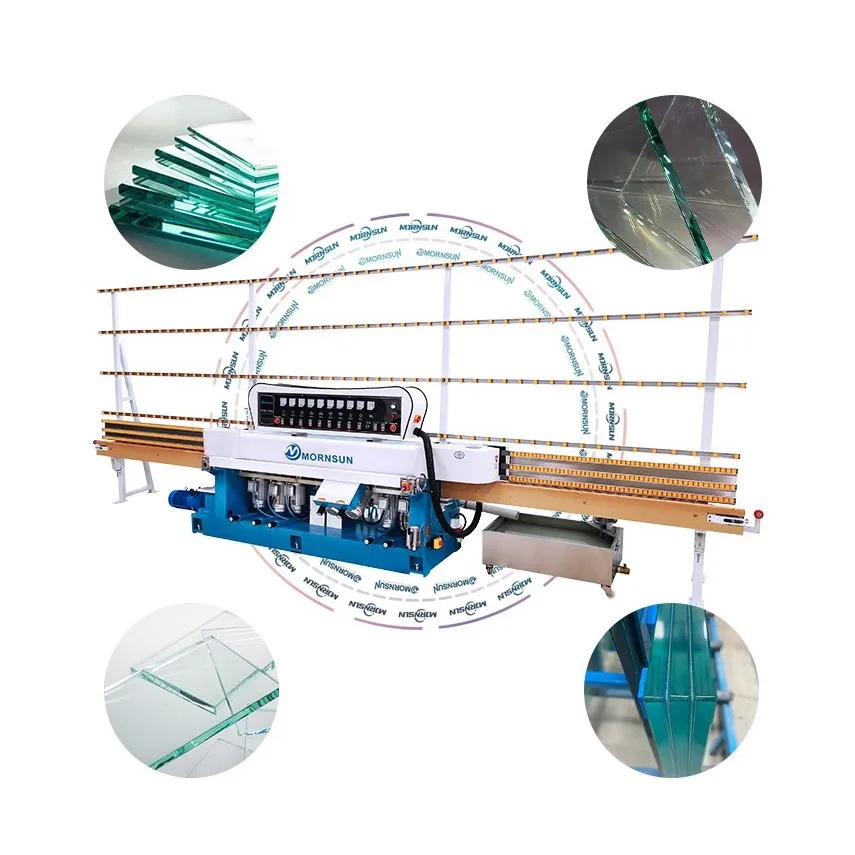

Автоматическая полировальная машина с 9 головками для стекла

Заводская розетка все в одном Лучшая Профессиональная Автоматическая настольная машина для резки стекла с ЧПУ

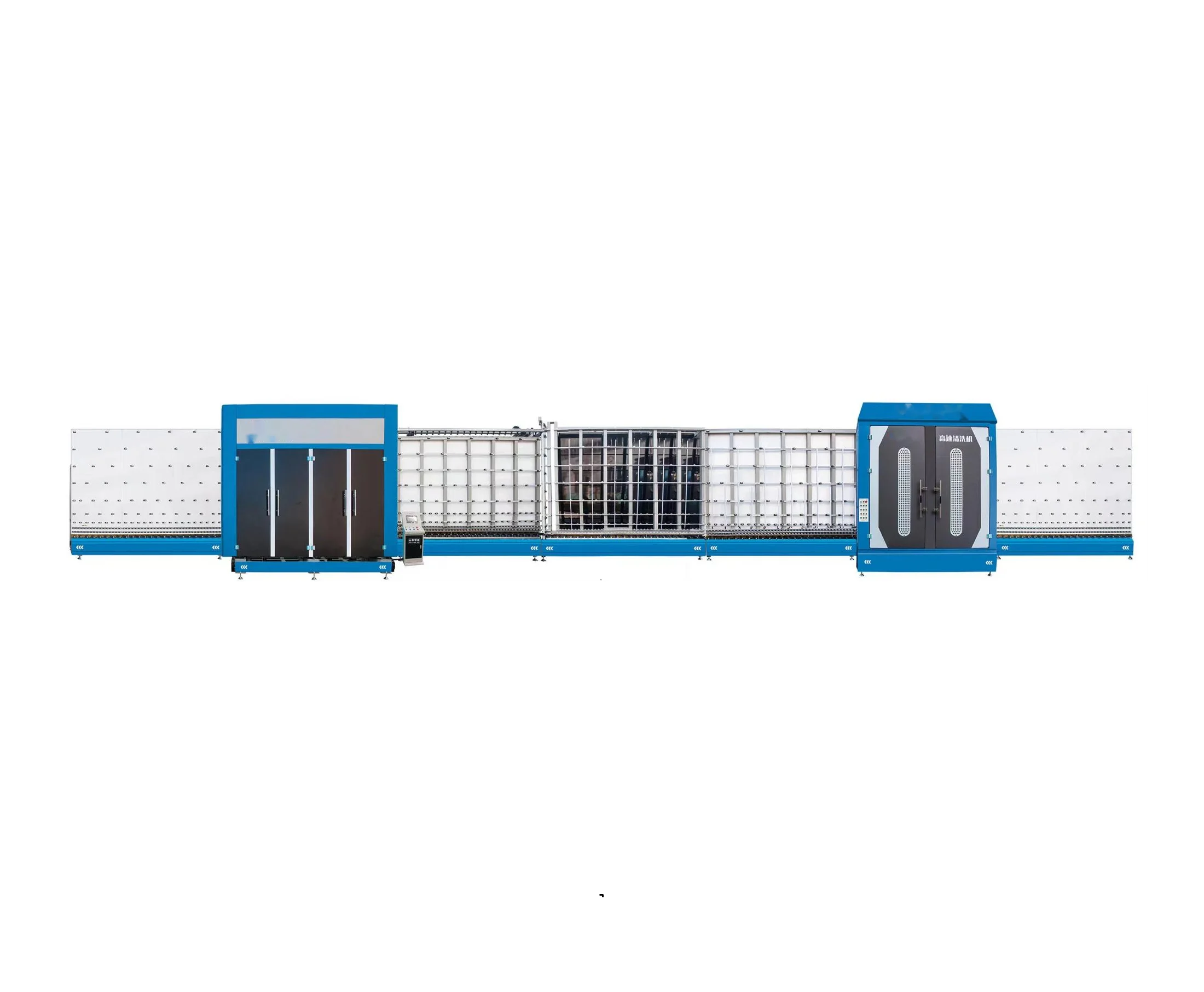

Высокое качество изоляционного стекла Герметик Производственной Линии машина для продажи

Высококачественная линия машины для нанесения стеклянного герметика обработки стекла

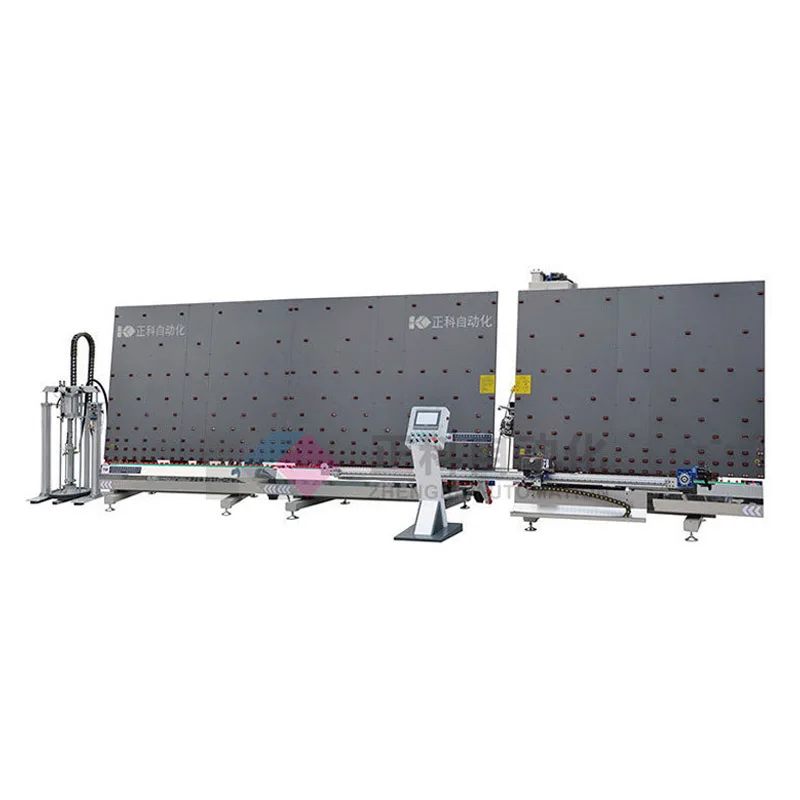

Высокое качество герметизации робот для изоляционного стекла

Автоматический изолированный стеклянный герметизирующий робот 2500x3700 мм

SHANDONG RUITE Новая Автоматическая Машина для мойки и сушки стекла

Новые поступления

Новинки товаров от производителей по оптовым ценам