Прямой компьютер алюминиевый тепловыделение персонального компьютера оборудование для водяного охлаждения

- Категория: Other Fabrication Services >>>

- Поставщик: Nanjing Metalli Industrial Co. Limited

Сохранить в закладки 1600524731558:

Описание и отзывы

Характеристики

PRODUCT SPECIFICATION FOR AUTOMOTIVE EGR VALVE COOLER | ||||||||

NO. | ITEM DESCRIPTION | CONTENT | ||||||

1 | Material | Aluminum | ||||||

2 | Dimension L*W*H | Customizable | ||||||

3 | Joining Method | Brazing, welding or other suitable techniques | ||||||

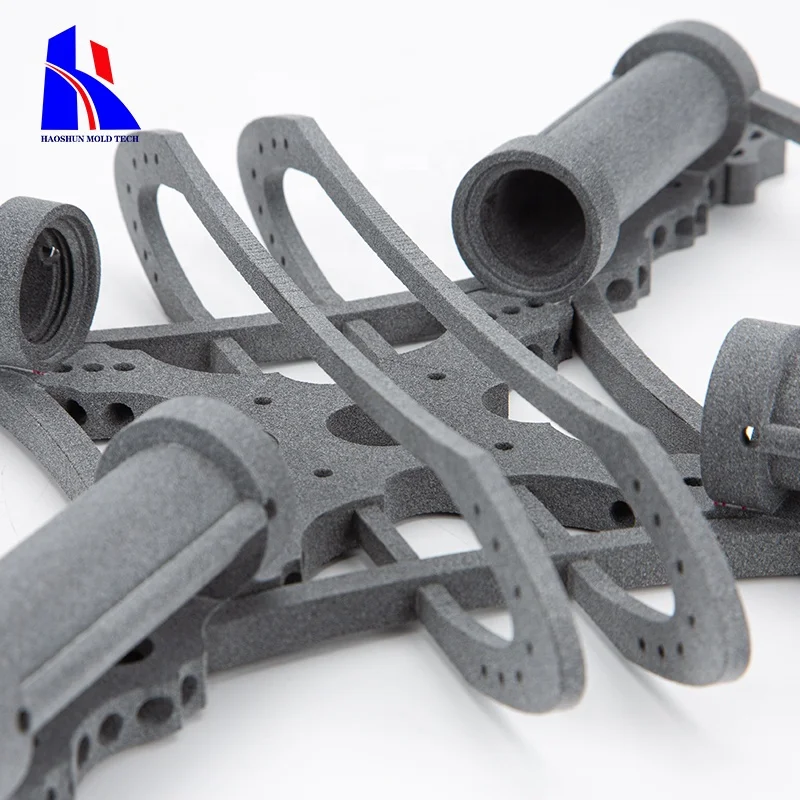

4 | Manufacturing technique for inner passage | CNC machining, extrusion or other suitable processes | ||||||

5 | Recommended Coolants | Deionized Water,Inhibited Glycol and Water,Dielectric fluid | ||||||

6 | Surface finish | Mill finish,anodizaiton or chemical coating | ||||||

7 | Place of Origin | China | ||||||

8 | Packing way | To be packed in carton box or plywood case with films protection | ||||||

Specifications

Very useful water cooling radiator for computer.

5 types for you to choose from, including 90mm, 120mm, 240mm, 360mm, 480mm.

With threaded port, you need to buy proper pipe joint for connection.

Comes with aluminum pipes, can dissipate heat more fast.

Item Name: Water Cooling Radiator

5 types for you to choose from, including 90mm, 120mm, 240mm, 360mm, 480mm.

With threaded port, you need to buy proper pipe joint for connection.

Comes with aluminum pipes, can dissipate heat more fast.

Item Name: Water Cooling Radiator

A series of available Sizes or Specifications for Cold Plates

►90mm Size(L x W x T): 13.5cm x 9.8cm x 3.2cm/5.32" x 3.85" x 1.26" (Approx.)

►120mm Size(L x W x T): 15.7cm x 12cm x 3.2cm/6.18" x 4.72" x 1.26" (Approx.)

►240mm Size(L x W x T): 27.5cm x 12cm x 3.2cm/10.83" x 4.72" x 1.26" (Approx.)

►360mm Size(L x W x T): 39.3cm x 12cm x 3.2cm/15.47" x 4.72" x 1.26" (Approx.)

Nanjing Metalli-your ideal partner for thermal management and metal fabrication solutions

✅ Since 2008, Nanjing Metalli has been focusing on thermal management field. Our capabilities cover a wide range that provide you one-stop solution quicker and easier. Our main capabilities include:

◇ Vacuum Brazing and Controlled Atmosphere Brazing

◇ CNC machining

◇ Welding

◇ Aluminum extrusion

◇ Aluminum die casting

◇ Sheet metal fabrication covering laser cutting, stamping, drawing and bending

◇ Surface coating

✅We emphasis prototype process. we use our vast experience in fluid dynamics, thermal performance, and material compatibility to optimize your design. To perform advanced thermal analysis, our engineers use simulation software like CFD, 6 Sigma. In addition to providing expert thermal and mechanical design engineering, we ensure that your products fit DFM concept so that your products can be built to your exact specifications as well as meet your delivery schedule.

✅ We see quality aspects from manufacturing viewpoints. Focusing more on monitoring and minimizing process variable to keep stable quality level. Delivered products are performed 100% inspection or testing. Less worries of quality risk and loss

✅ Our lean manufacturing and continuous improvement program aim at eliminating all wastes that do not add values. Our customers do not need to pay for wastes. The cost will be more and more competitive that help grow up your business and build your success.

◇ Vacuum Brazing and Controlled Atmosphere Brazing

◇ CNC machining

◇ Welding

◇ Aluminum extrusion

◇ Aluminum die casting

◇ Sheet metal fabrication covering laser cutting, stamping, drawing and bending

◇ Surface coating

✅We emphasis prototype process. we use our vast experience in fluid dynamics, thermal performance, and material compatibility to optimize your design. To perform advanced thermal analysis, our engineers use simulation software like CFD, 6 Sigma. In addition to providing expert thermal and mechanical design engineering, we ensure that your products fit DFM concept so that your products can be built to your exact specifications as well as meet your delivery schedule.

✅ We see quality aspects from manufacturing viewpoints. Focusing more on monitoring and minimizing process variable to keep stable quality level. Delivered products are performed 100% inspection or testing. Less worries of quality risk and loss

✅ Our lean manufacturing and continuous improvement program aim at eliminating all wastes that do not add values. Our customers do not need to pay for wastes. The cost will be more and more competitive that help grow up your business and build your success.

Vacuum Brazing Furnace

CNC Machine

Meeting Discussion with Customers

ISO9001 Certified

100% tested or Inspected

Thermal Simulation Analysis

Похожие товары

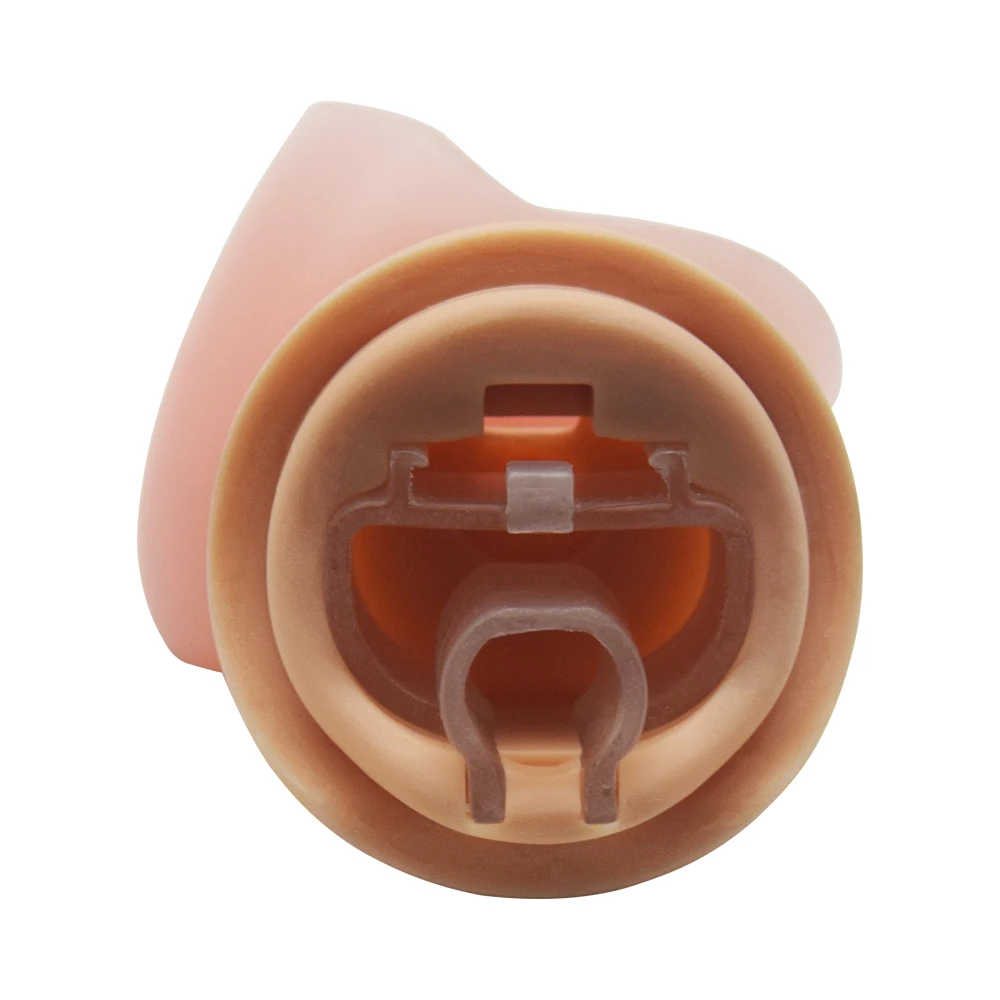

Пластиковые изделия на заказ детали для слухового аппарата вакуумного литья из АБС-пластика поликарбоната силиконовая

20,00 $ - 80,00 $

VICSUN изготовление листового металла штамповка анодирование порошка цинковое покрытие заводское обслуживание

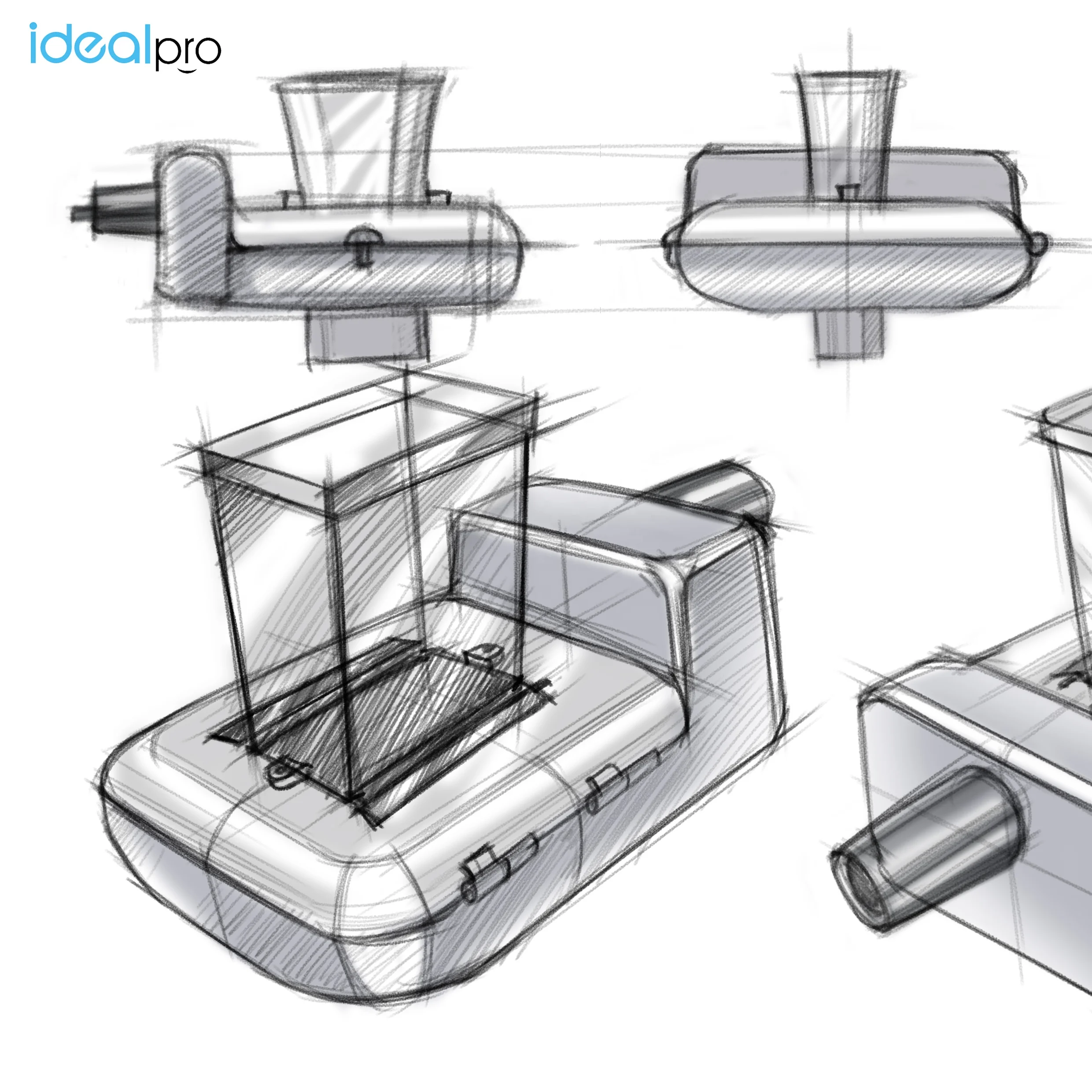

3D-рисунок промышленный дизайн и разработка индивидуального дизайна продукта услуги по

OEM обработка изготовленных на заказ мотоциклетных машин Cnc 3D аксессуары для

9,00 $ - 10,00 $

RUS003 EN124-1994 G500-7 Люк чугунный тип света с замком B125 крышка люка из кованого

800,00 $ - 900,00 $

Позолоченный Черный Цвет Пользовательский Кабель-адаптер Поддержка full 1080P конвертер Кабель компьютерные

0,30 $ - 1,00 $

25mm Forged Grinding Steel Balls for sale aluminium pressure die

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $