Превосходный цилиндрический сварочный аппарат продольная сварочная машина чайник цилиндр сжиженного углеводородного газа

- Категория: Seam Welders >>>

- Поставщик: Dalian J&Y Heavy Machine Co. Ltd.

Сохранить в закладки 1600526943927:

Описание и отзывы

Характеристики

Contacts: David Liu

Tel: +86-411-82766928

Fax: +86-411-39015062

Email: Liu@weldcnc.com

Mob/Whatsapp: +86 133 9411 0095

Product Description

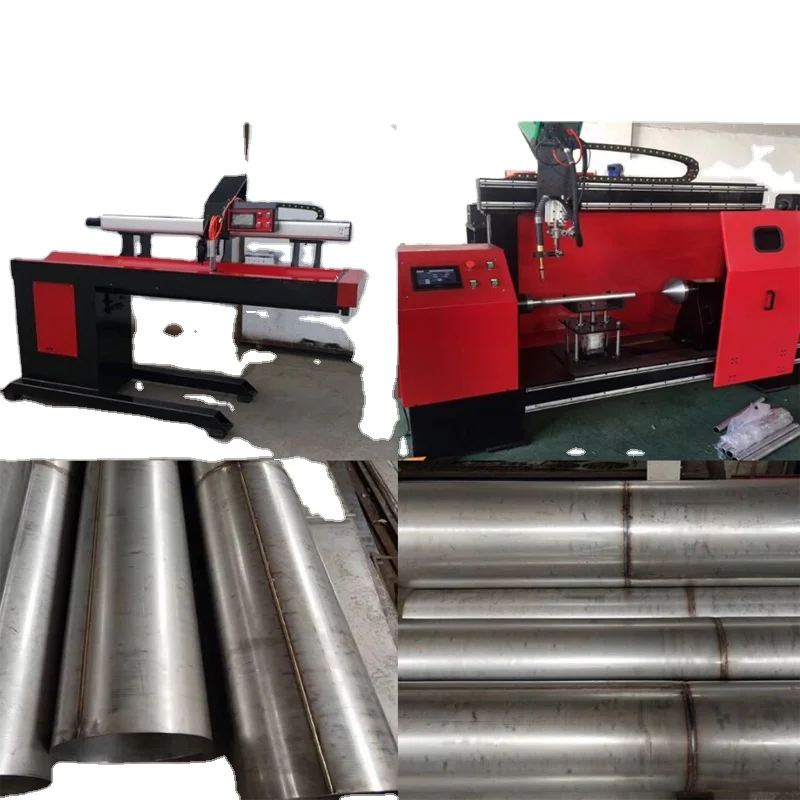

Circumferential Seam Welding Main Purpose and scope

Hydraulic cylinder circumferential welding equipment is mainly used for girth weld of hydraulic cylinder and piston rod automatic multi-layer swing welding; the structure is horizontal bed type. According to the actual needs of users, it can be single or double torch welding, welding head axial movement is driven by servo motor. In order to adapt to different length of work piece, tailstock moving using manual and pneumatic jacking.

Weld appearance beautiful, uniform, penetration, weld width meets the requirements. Welding operation simple and flexible; work piece clamping convenient; reliable performance, convenient loading and unloading. high degree of automation, low labor intensity of workers.

DESCRIPTION

Circular seam welding machine mainly used for circular weld welding of carbon steel, stainless steel and other metal workpieces. It can weld similar workpiece appearance such as air reservoir, water heater, fire tube, drive shaft, shock absorber, muffler, container can, pipe butt joint, pipe flange, pipe elbow tee and other circular seam welding.

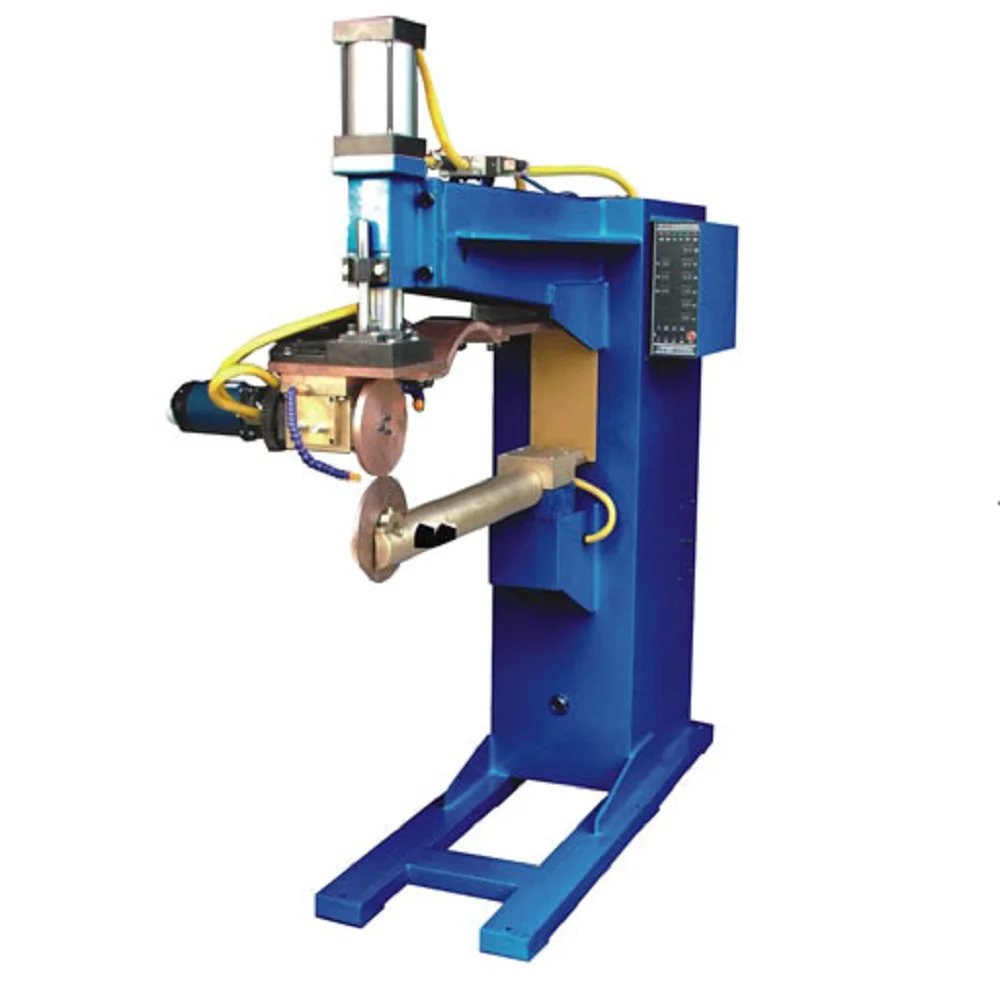

PERFORMANCE

The bed body adopts a horizontal structure, which is finished by annealing the welded structural parts to ensure that the bed rail is not deformed;The rotary head is driven by DC motor or AC variable frequency motor, and the speed is stable and reliable;A welding fixture or a three-jaw chuck is mounted on the end of the spindle for clamping and positioning the workpiece;The tailstock can be pneumatically or manually tightened, and the end can be selected according to different workpiece forms, different welding fixtures or movable tips.

Company Information

Main Technical Data

Input votage | (3-phase 5- wire) AC 380V /220V 50Hz | Torch angle | Adjustable 0-90 degree |

Input capacity | 35.8KVA | Torch up and down adjustment | 80mm |

Welding speed | 0.2~2r/min | Torch left and right adjustment | 80mm |

Rated output voltage range | 15-50V | Welding wire diameter | φ10~ φ1.2mm |

Rated output electric current range | 60~630A | Work piece diameter | φ100~ φ600mm |

No- load output voltage | 70V | Work piece length | ≤3000mm |

Motor total power | 2KW | Welding mode | Multilayer swinging or multilayerstep, spiral |

Equipment Application and Scope

1. Application:

304 stainless steel longitudinal and circumference seam welding

1. Application:

304 stainless steel longitudinal and circumference seam welding

cylinder diameter | 400mm-1200mm |

cylinder length | ≤ 2500mm |

cylinder wall thickness | 2mm-6mm |

2. Job status: work piece welding surface is smooth, the largest seam gap less than 2mm.

3. condition of work piece surface: no pollution, serious corrosion etc.

4. Work piece state before welding: before welding, workpiece are firmly spot welded, the joints are clean.

5. The equipment pneumatically clamps the head and tail of the work piece and turns the work piece automatically.

3. condition of work piece surface: no pollution, serious corrosion etc.

4. Work piece state before welding: before welding, workpiece are firmly spot welded, the joints are clean.

5. The equipment pneumatically clamps the head and tail of the work piece and turns the work piece automatically.

Flanges are welded on a welding positioner. Two sets of systems are using one power source, and the equipment can realize the switch between different welding spot.

MACHINE SUMMARY

Using industry PLC, Touch screen interface, servo motor and AC frequency converter to realize automatic welding.

The machine has the following characteristics:

1. Industrial plc control the operation of the whole machine, the control is accurate and reliable; the operation is simple and convenient.

2. Adopts ac inverter to regulate speed. Realize welding speed steeples adjustment and the adjustment is convenient and reliable, large range, high precision, stable and reliable operation.

3. Using high definition color touch screen, easy to set all kinds of welding process parameters.

4. Plenty of welding process parameters, to acheive full functional automatic welding.

5. Using high quality water cooling push wire welding torch, welding torch with up and down, left and right adjustment and angle adjustment function.

6. Using mechanical positioning. Pneumatic jacking work piece, accurate positioning.

7. In welding process, torch swing, can realize surfacing. Built-up welding automatic multilayer welding process.

8. Process integration is powerful, user according to the work piece welding requirements, has flexible choices.

9. Improve the work eficiency, reduces the labor intensity of the worker.

The machine has the following characteristics:

1. Industrial plc control the operation of the whole machine, the control is accurate and reliable; the operation is simple and convenient.

2. Adopts ac inverter to regulate speed. Realize welding speed steeples adjustment and the adjustment is convenient and reliable, large range, high precision, stable and reliable operation.

3. Using high definition color touch screen, easy to set all kinds of welding process parameters.

4. Plenty of welding process parameters, to acheive full functional automatic welding.

5. Using high quality water cooling push wire welding torch, welding torch with up and down, left and right adjustment and angle adjustment function.

6. Using mechanical positioning. Pneumatic jacking work piece, accurate positioning.

7. In welding process, torch swing, can realize surfacing. Built-up welding automatic multilayer welding process.

8. Process integration is powerful, user according to the work piece welding requirements, has flexible choices.

9. Improve the work eficiency, reduces the labor intensity of the worker.

Our order and visitors

Since its establishment, Dalian J&Y Machinery Co., Ltd. has been adhering to the enterprise spirit of "pursuing excellence and exceeding expectations", insisting on improving user satisfaction and its own service level, receiving customers with high-level and convenient services, and devoting This kind of demand has won unanimous praise from customers.

Products Recommended

Packaging & Shipping

Company Profile

Company Information

Dalian J&Y Machinery Equipment Co., Ltd. was established in 2012.We are an enterprise specializing in the development and sales of CNC machine tools and automatic welding equipment. Our main products are shearing machines, bending machines, rolling machines, punching and shearing machines, presses, hydraulic presses, plasma cutting machines, sealing machines, welding equipment, polishing equipment and so on.

Dalian J&Y Machinery Equipment Co., Ltd. covers an area of 66,600 square meters with a total investment of more than 150 million yuan. There are more than 120 employees, including 30 professional and technical personnel and 10 personnel with intermediate and senior titles. The company has excellent equipment, strong technical force, advanced manufacturing technology,complete testing methods and perfect quality system. There are more than 150 main equipment, 5 automated and semi-automated production lines, with an annual production capacity of 50,000 sets.

We adhere to the principle of "customers are the first priority" and continue to pursue innovation and development. We also strive to develop high-tech products to meet the needs of customers in different industries. Our goal is to become the most competitive enterprise in the field of providing automation products and cutting and welding equipment industry services. In short, join us and create a better future together, because J&Y can become your most reliable business partner!

Our Certificate

Contact Us

Contacts: David Liu

Tel: +86-411-82766928

Fax: +86-411-39015062

Email: Liu@weldcnc.com

Mob/Whatsapp: +86 133 9411 0095

FAQ

Q1.What is our main product ?

A1: Our company is a professional sheet metal processing machinery by JIUYING.HEAVY MACHINE CO.,LTD. in 1988. Concentrate on four column press machine, embossing door press machine, bending machine, shearing machine, cnc plasma cutting machine, rolling machine, punching machine, hydraulic ironworker, welding equipment.

All these machine will be solved for the tank, pan, trolley, ect.

Q2.When can I get the price ?

A2:We usually offer the quotation within 8hours, For urgent offer, please contact with us for special.

Q3.What is the Trade Term?

A3: We accept Ex-work factory , FOB Dalian, CNF or CIF, as your requirement.

Q4.How long is our Production leading time?

A4: It depends on type of equipment.

We often deliver the goods within 35days.

Q5.What is the Payment term?

A5: By T/T before shipment or By L/C at sight.

Q6. During shipping, if there is a damage to products, how do you get replacement?

A6: Firstly, we should investigate the reason cause the damage. At the same time, we will claim for the insurance by ourselves or assist the buyer.

Secondly we will send the replacement to the buyer. The responsible person for above damage will take charge of the cost of the replacement.

Q7. What are your terms of packing?

A7: Packing: export worthy package suitable for container transportation.

Wooden case, iron pallet, plastic film ect.

Q8. Do you test all your goods before delivery?

A8: Yes, we have 100% test before delivery.

Q9: Where is your factory located?

A9: Our factory is located in Dalian, Liaoning province.

Q10: What is your warranty?

A10: Warranty: 24 months after commercial running or 18months from the date of shipment, subject to the earlier expiry.

Q11: Can you arrange thirty party pre-shipment inspection?

A11: Pre-shipment inspection: Supplier’s pre-shipment inspection is Final; pre-shipment inspection by third Party on buyers cost.

Q12:Can we do our OEM logo?

A12:Yes, for the products with drawing supplied by you, we of course apply your logo

A1: Our company is a professional sheet metal processing machinery by JIUYING.HEAVY MACHINE CO.,LTD. in 1988. Concentrate on four column press machine, embossing door press machine, bending machine, shearing machine, cnc plasma cutting machine, rolling machine, punching machine, hydraulic ironworker, welding equipment.

All these machine will be solved for the tank, pan, trolley, ect.

Q2.When can I get the price ?

A2:We usually offer the quotation within 8hours, For urgent offer, please contact with us for special.

Q3.What is the Trade Term?

A3: We accept Ex-work factory , FOB Dalian, CNF or CIF, as your requirement.

Q4.How long is our Production leading time?

A4: It depends on type of equipment.

We often deliver the goods within 35days.

Q5.What is the Payment term?

A5: By T/T before shipment or By L/C at sight.

Q6. During shipping, if there is a damage to products, how do you get replacement?

A6: Firstly, we should investigate the reason cause the damage. At the same time, we will claim for the insurance by ourselves or assist the buyer.

Secondly we will send the replacement to the buyer. The responsible person for above damage will take charge of the cost of the replacement.

Q7. What are your terms of packing?

A7: Packing: export worthy package suitable for container transportation.

Wooden case, iron pallet, plastic film ect.

Q8. Do you test all your goods before delivery?

A8: Yes, we have 100% test before delivery.

Q9: Where is your factory located?

A9: Our factory is located in Dalian, Liaoning province.

Q10: What is your warranty?

A10: Warranty: 24 months after commercial running or 18months from the date of shipment, subject to the earlier expiry.

Q11: Can you arrange thirty party pre-shipment inspection?

A11: Pre-shipment inspection: Supplier’s pre-shipment inspection is Final; pre-shipment inspection by third Party on buyers cost.

Q12:Can we do our OEM logo?

A12:Yes, for the products with drawing supplied by you, we of course apply your logo

Похожие товары

ZF1000 Автоматическая аргоновая дуговая машина для продольной сварки швов металлического цилиндра

Высокочастотный ПВХ НПВХ профиль одноголовочный сварочный аппарат/двухсторонний окно угловой аппарат для окна и двери

110 927,50 ₽ - 138 659,38 ₽

Оптовая цена сварочный аппарат для окон из ПВХ и пластика одноголовочный изготовления дверей

110 927,50 ₽ - 138 659,38 ₽

ПВХ профиль одноголовочный сварочный аппарат заводская цена пластиковые окна для изготовления окон и дверей из

110 927,50 ₽ - 138 659,38 ₽

Автоматическая Круглая стальная труба круглая сварочная машина Вертикальная

432 617,25 ₽

160KVA CNC если машина для сварки листового металла нержавеющая сталь США резервуар вертикальный выпрямитель шва

388 246,25 ₽ - 1 109 275,00 ₽

Можно изготовить на заказ рулонный сварочный аппарат для стали

Новые поступления

Новинки товаров от производителей по оптовым ценам

OrionStars онлайн-машина для рыбалки и свинга высокоприбыльная монетная игра США оптовая продажа агент с высокой прибылью Разыскивается

Рекламный надувной самолет украшение для костюма самолета ходячие костюмы продажи

C100 % восковая ткань с принтом китайские поставщики поставляют настраиваемые печатные африканские восковые ткани

0,93-0,97 $

Прямые продажи с фабрики могут быть оптовые складные тележки для покупок Удобные и уличные продуктовые

8,39-9,89 $

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $