Профессиональный ротационная сушильная печь для известняка негашеная известь обжигательная промышленных активная обжига извести завод

- Категория: >>>

- Поставщик: Gongyi Derui Machinery Co. Ltd.

Сохранить в закладки 1600530174171:

Описание и отзывы

Характеристики

Limestone calcination rotary kiln

Product introduction and application

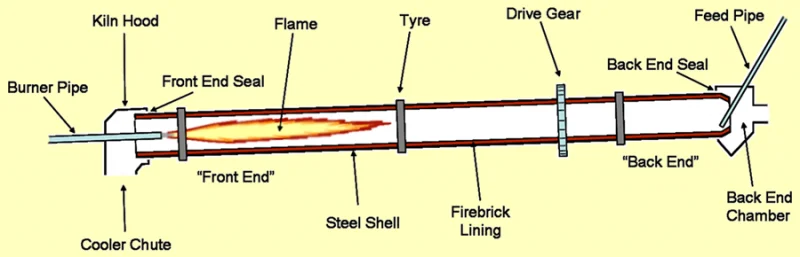

The rotary kiln produced has advanced structure. It can effectively improve preheating effect with its low resistance vertical preheater. After the material is preheated, the feeding decomposition rate can reach 20%-25%, thus can directly make use of 10-15mm fine fraction materials. The reliable airtight two-ends combination squama make the air leakage factor under 10%. The usage of compound refractory reduces radiation loss.Rotary kiln belongs to building material equipment, which can be divided into cement kiln,metallurgy chemical kiln and lime kiln according to different materials.

The structure chracteristic:

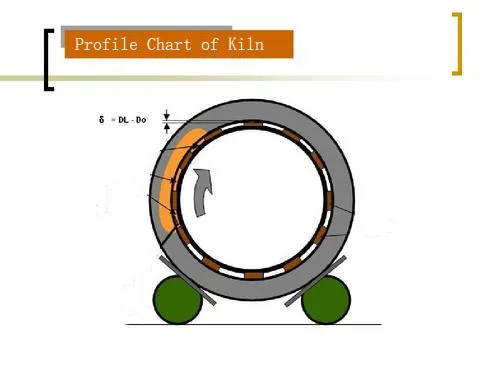

1. The rotary kiln shell design fully take into consideration of the corner at shell flexible supporting to extend the lifetime of refractory bricks and castings.

2. Adopt supporing roller bearing with big diameter and small ratio between length and diameter to improve the reliability. The bearing is automatic self-sligning bearing.

3. The better sealing effect of new type open gear hood sealing type.

4. The spring lamination overlying type lexible sealing, double layer spring lamination sealing increase the heat insulation layer to improve the reliability and lifetime.

Working Principle

Derui Rotary kiln cylinder composed of steel plate, cylinder body with build by laying bricks or stones of refractory lining, and horizontal line into slope, three belting leather in each block supporting device, in the material near the end belting leather across the inner cylinder with tangential spring plate fixed on a big gear ring, which is a small gear meshing. During normal operation, the main drive motor is transmitted to the open-type gear device by the main drive motor, which drives the rotary kiln.Materials are calcined from the end of the kiln. Due to the effect of tilting and slow rotation of the cylinder, the material is along the circumference of a circle and tumbling along the axial direction (from high to low) mobile, continue to complete the process, and generate the clinker kiln hood into the cooling machine cooling.The fuel is sprayed into the kiln by the kiln head, and the waste gas and materials produced in the furnace are exchanged for impact crusher, which is exported by the kiln tail.

Model(m) | Diameter (m) | Length(m) | Slope(%) | Capacity(t/h) | Rotate Speed (r/min) | Motor Power(kw) | Weight(T) |

φ1.4×33 | 1.4 | 33 | 3 | 0.9-1.3 | 0.39-3.96 | 18.5 | 47.5 |

φ1.6×33 | 1.6 | 33 | 4 | 1.2-1.9 | 0.26-2.63 | 22 | 50 |

φ1.6×36 | 1.6 | 36 | 4 | 1.2-1.9 | 0.26-2.63 | 22 | 52 |

φ1.8×32 | 1.8 | 32 | 4 | 1.9-2.4 | 0.16-1.62 | 30 | 78.2 |

φ1.8×45 | 1.8 | 45 | 4 | 2.8-3.34 | 0.21-2.11 | 30 | 95.2 |

φ1.9×36 | 1.9 | 36 | 3.5 | 1.2-1.7 | 0.29-2.93 | 30 | 86.3 |

φ1.9×45 | 1.9 | 45 | 3.5 | 1.65-2.5 | 0.29-2.93 | 37 | 109 |

φ2.2×48 | 2.2 | 48 | 3 | 1.9-2.1 | 0.98-2.93 | 55 | 141 |

φ2.5×40 | 2.5 | 40 | 3.5 | 6.0-7 | 0.44-2.44 | 55 | 139.61 |

φ2.5×50 | 2.5 | 50 | 3.5 | 7.0-8.0 | 0.48-1.44 | 55 | 179.6 |

φ2.5×54 | 2.5 | 54 | 3.5 | 8.0-8.6 | 0.48-1.44 | 55 | 196.29 |

φ2.7×42 | 2.7 | 42 | 3.5 | 10.0-11.0 | 0.10-1.52 | 55 | 198.5 |

φ2.8×44 | 2.8 | 44 | 3.5 | 11-12.5 | 0.80-2.39 | 55 | 198.6 |

φ3.0×45 | 3 | 45 | 3.5 | 13.3-16.9 | 0.5-1.35 | 55 | 223 |

φ3.2×52 | 3.2 | 52 | 3.5 | 16-18.5 | 0.48-2.44 | 110 | 278 |

Q:What is the MOQ?

R:MOQ is 1 set,we allow OEM and sample order,but the cost are paid by your side.

Q: Where is your factory located? How can I visit there?

R: Our factory is located in Zhengzhou City, Henan Province, China.Contact us ahead before you go visit,then we can fully arrange the schedule and meet you.Welcome to visit us!

Q: What is the warranty time of your products?

R: The warranty time is 12 months from the date of the commissioning.After the warranty, any questions and needs,please contact us.

Q: How does your factory do regarding quality control?

R: All products have to pass strict inspection before they ship out.And we have gained ISO9001:2008 authentication.If you need other certificate and quality control,please contact us.

Gongyi Derui Machinery Co., LTD entered the mechanical industry from the beginning of the 1980’s, earlier than most factories. With the company philosophy these years, our products are sold to many customers from home and abroad, popular in India, Russia, Kazakhstan, Africa, South America, Mid-East, Southeast Asia, and almost 30 countries and areas. And it is our honor to make a contribution of to the development of these countries.

Growth is only a process, and the brilliance is the new beginning. In order to respond positively to the good policy of The Belt and Road, we will, as always, provide higher and higher quality products and service, to win more and more acclamation and respect for Chinese national industry. Review ourselves with serious attitude, and win the trust with excellent quality. We sincerely hope to take win-win cooperation with entrepreneurs and companies all over the world, to develop the market together.

Похожие товары

Производство Китай, высокое Quality3-ply безуглеродная бумага, рулоны с безуглеродной NCR ATM-бумагой для получения арендной платы

Мужская водонепроницаемая куртка из 100% полиэстера, импортная застежка-молния, машинная стирка, Поставка со склада из бангладеш

Аудио декодер модуль усилитель MP3 модуль микро One-119B Amp

5 слоев 9,5x11 дюймов NCR компьютерная бумага непрерывная бумага

Ювелирные изделия Redleaf плоский овальный кабошон камень Lcolor свободный драгоценный рубин синий синтетический

Треугольная гусеница шириной 255 резиновые гусеничные системы ATV/UTV/транспортировка по бездорожью снегу водно-болотным угодиям

Компактный складной Дрон WUPRO 4k HD пикселей, недорогой мини Дрон с Wi-Fi и передачей в режиме реального времени, Дроны с безголовым режимом и регулировкой скорости

Новые поступления

Новинки товаров от производителей по оптовым ценам