Универсальная автоматическая разливочная машина для косметики многофункциональная новая модель 2022

- Категория: >>>

- Поставщик: Shanghai Kanuo Industrial Co. Ltd.

Сохранить в закладки 1600530763250:

Описание и отзывы

Характеристики

Product Description

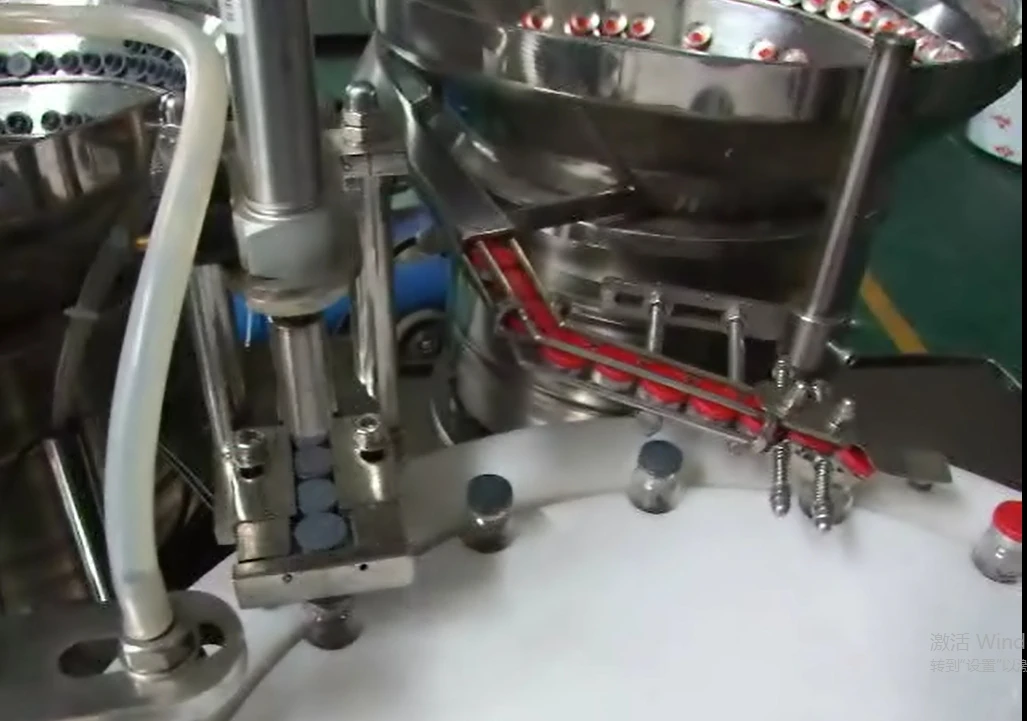

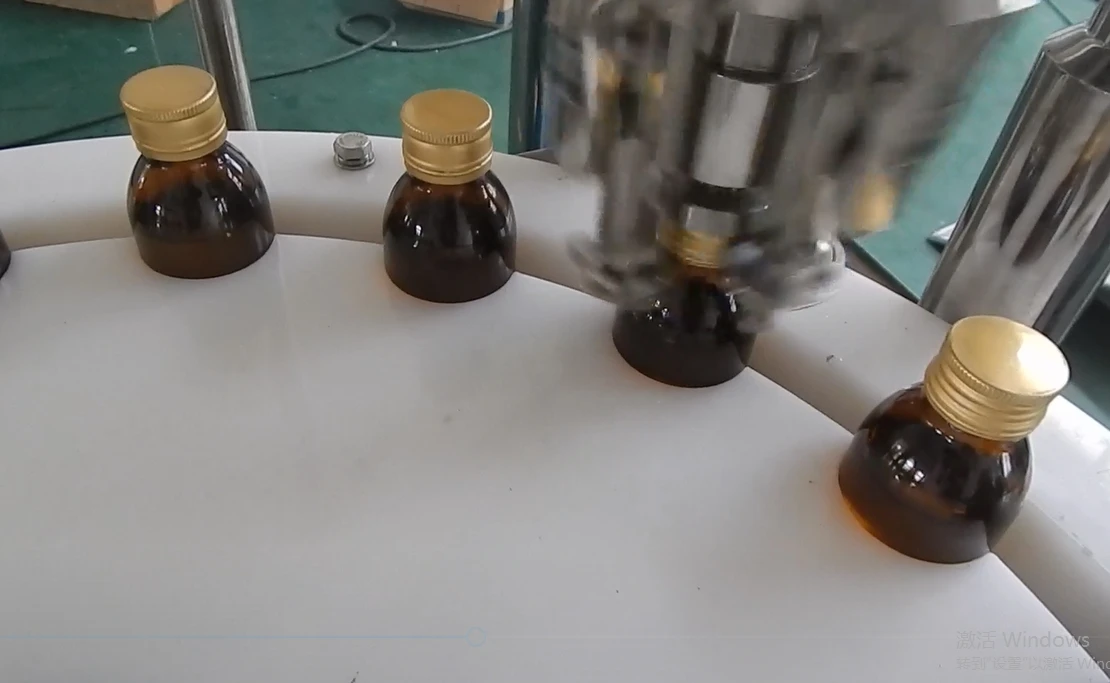

The filling capping and labeling machine is composed of the procedures as the auto-setting bottle, bottle washing machine,

different filling machines and capping machine, and aluminum foil sealing machines, labeling machine. This produce line is the

most ideal one of produce oil, liquid material and so on. It can be equipped with different straight-line-filling heads according

to the requirement of clients, which meets the requirement of GMP. we can do customized machine.

different filling machines and capping machine, and aluminum foil sealing machines, labeling machine. This produce line is the

most ideal one of produce oil, liquid material and so on. It can be equipped with different straight-line-filling heads according

to the requirement of clients, which meets the requirement of GMP. we can do customized machine.

Object Size | 30-280 mm(H),20-200 mm(W) |

Label Size | 15-140 mm(H),25-300 mm(W) |

Filling accuracy | ±1mm |

Filling speed | Production speed:60-200pcs/min |

power supply | 110/220V, 1.5HP, 50/60Hz |

note | we can also make the filling capping labeling machine according to your special other size range label and object size |

FEATURES

* Controlled by servo system.

* Adjustable filling speed

* Accurate to ±0.5% ( with drinking water )

* Integrated digital control with PLC and high tech touch screen controls for easy operation.

* Designed for easy changeover and cleaning.

* Professional manufacturing techniques using the ISO-9001 system.

* Sturdy conveyor system driven by SERVO motor. Adjustable conveyor guide rails to accommodate with different products.

* GMP standard stainless steel.

* Drip detect system.

* Bottle holding mechanism for the best position of the bottles before filling action.

* No bottle-no fill system.

* Bottle jam detection.

* Warning light and buzz alarm on production error.

* Filling zone protected by interlock guards for safety registration

* ABB circuit breaker for overload protection.

* Memory slots for storing filling parameters for future operation

* Easy to install and operate, requiring minimum maintenance for maximum performance and useful life.

* Delicate filler structure with high quality finish,

* Volume is easily adjusted through touch screen. Filling pistons are controlled by servo system.

* Individual piston adjustment for fine tuning.

* Digital control system to enable multiple filling actions on the same bottle for double, triple and more.

* Fully automatic rise for nozzles, adjustment can be done on touch screen

* Nozzles can set to be above bottle mouth or bottom up, synchronizing with liquid level (beneath or above) to eliminate bubbling

of foamy liquids.

* Adjustable speed while filling, it can fill slowly at the beginning and then accelerate to faster speed, finally slow down once

again to finish up. This can prevent foamy liquids from bubbling and avoid spillage.

* Adjustable filling speed

* Accurate to ±0.5% ( with drinking water )

* Integrated digital control with PLC and high tech touch screen controls for easy operation.

* Designed for easy changeover and cleaning.

* Professional manufacturing techniques using the ISO-9001 system.

* Sturdy conveyor system driven by SERVO motor. Adjustable conveyor guide rails to accommodate with different products.

* GMP standard stainless steel.

* Drip detect system.

* Bottle holding mechanism for the best position of the bottles before filling action.

* No bottle-no fill system.

* Bottle jam detection.

* Warning light and buzz alarm on production error.

* Filling zone protected by interlock guards for safety registration

* ABB circuit breaker for overload protection.

* Memory slots for storing filling parameters for future operation

* Easy to install and operate, requiring minimum maintenance for maximum performance and useful life.

* Delicate filler structure with high quality finish,

* Volume is easily adjusted through touch screen. Filling pistons are controlled by servo system.

* Individual piston adjustment for fine tuning.

* Digital control system to enable multiple filling actions on the same bottle for double, triple and more.

* Fully automatic rise for nozzles, adjustment can be done on touch screen

* Nozzles can set to be above bottle mouth or bottom up, synchronizing with liquid level (beneath or above) to eliminate bubbling

of foamy liquids.

* Adjustable speed while filling, it can fill slowly at the beginning and then accelerate to faster speed, finally slow down once

again to finish up. This can prevent foamy liquids from bubbling and avoid spillage.

Related Products

Packing&Shipping

Packing : wooden case with strong seaworthy packing suitable for exporting.

Packing Size: 3000*1350*1600mm

Net Weight: 300kgs;

Gross Weight: 250kgs.

Shipping : By sea or air.

Packing Size: 3000*1350*1600mm

Net Weight: 300kgs;

Gross Weight: 250kgs.

Shipping : By sea or air.

Company Profile

Shanghai Kanuo industrial co., company is a top company that manufactures good & high quality filling machine , capping machine

labeling machine, starting from 2006. The company provides the customized products and OEM service. Various new collections and

design are coming out each month with the current needs in the market. The factory own the proficient skill and updated machine

labeling machine, starting from 2006. The company provides the customized products and OEM service. Various new collections and

design are coming out each month with the current needs in the market. The factory own the proficient skill and updated machine

Cooperate brand

After Sales Service

1.We have a team for after-sale service.

2.All of us trust than good service is as important as good quality.

3.If any problems in using,please contact us.

4.For the products within the warranty period,we will slove the problem for you for free.

5.For the products out of the warrany period,we also will offer the best rate for the replacement to you.

2.All of us trust than good service is as important as good quality.

3.If any problems in using,please contact us.

4.For the products within the warranty period,we will slove the problem for you for free.

5.For the products out of the warrany period,we also will offer the best rate for the replacement to you.

Customer feedback

FAQ

Servo Drive System

KANUO's volumetric filling system utilizes the delicate servo drive system to control the main filling structure, achieving

high stability and precise positioning.

Vertical Driven Piston

Our exclusive servo control system coupled with the vertical movement of the filling piston provides long term energy saving and

also effectively reduces machine load rate.

Tool-Free Adjustment

Adjustments can be made through the PLC, completely tools-free, giving users a fast and efficient result. The delicate servo

control system design provides options for surface layer liquid filling, bottom layer liquid filling, and bottle neck (opening)

filling accordingly with different types of liquids.

High Accuracy

The delicate servo system controls the filling amount through precise piston strokes, providing high filling accuracy. The piston

is intelligently designed with an adjusting mechanism to enable users to obtain ultimate higher accuracy.

High Adapability

The Automatic Filling Machine can be used in food, cosmetics, and other industries. The

personalized control panel system is easy to use and offers effective result management through the production monitoring on the

PLC.

KANUO's volumetric filling system utilizes the delicate servo drive system to control the main filling structure, achieving

high stability and precise positioning.

Vertical Driven Piston

Our exclusive servo control system coupled with the vertical movement of the filling piston provides long term energy saving and

also effectively reduces machine load rate.

Tool-Free Adjustment

Adjustments can be made through the PLC, completely tools-free, giving users a fast and efficient result. The delicate servo

control system design provides options for surface layer liquid filling, bottom layer liquid filling, and bottle neck (opening)

filling accordingly with different types of liquids.

High Accuracy

The delicate servo system controls the filling amount through precise piston strokes, providing high filling accuracy. The piston

is intelligently designed with an adjusting mechanism to enable users to obtain ultimate higher accuracy.

High Adapability

The Automatic Filling Machine can be used in food, cosmetics, and other industries. The

personalized control panel system is easy to use and offers effective result management through the production monitoring on the

PLC.

Why Choose Us

The Filling Machine is widely used for food, cosmetics and other various industries.

The personalized control panel system provides users an easy operation experience and an effective management through production

monitoring on the PLC.

KN is an automatic vials feeding & arranging/detecting, filling, and capping machine. It can even handle special vial shapes

such as rotundity, flat, and prism-shaped vials. It can also handle many different kinds of stoppers, giving it an edge over

other similar machines in the world. It has met all GMP regulations through our company's superior design and manufacturing of

non-standard products. It is applicable for eyedrops, syrups, perfumes, shower gels, shampoos, nail polish

lotion and much more. Mobile/whatsapp/wechat : 0086 186 2101 8770

Skype: casiechen7

Email : casie@cnkanuo.com

The personalized control panel system provides users an easy operation experience and an effective management through production

monitoring on the PLC.

KN is an automatic vials feeding & arranging/detecting, filling, and capping machine. It can even handle special vial shapes

such as rotundity, flat, and prism-shaped vials. It can also handle many different kinds of stoppers, giving it an edge over

other similar machines in the world. It has met all GMP regulations through our company's superior design and manufacturing of

non-standard products. It is applicable for eyedrops, syrups, perfumes, shower gels, shampoos, nail polish

lotion and much more. Mobile/whatsapp/wechat : 0086 186 2101 8770

Skype: casiechen7

Email : casie@cnkanuo.com

Похожие товары

Электрический Настольный станок для резки плитки

1 250,00 $ - 1 261,00 $

Встраиваемый тип розетки Выдвижная розетка настольная розетка с зарядным устройством

8,00 $ - 18,00 $

4 направления, впитывающая влагу, 230 г/м2, 86% переработанный полиэстер, 14% спандекс, интерлок, ткань для леггинсов

3,67 $ - 5,55 $

Zibo высокоглиноземный керамический шлифовальный шар для керамических глазурных материалов

1,00 $ - 5,00 $

Волоконно-оптический самонесущий Ftth Gjyxch Gjyxfch 2 ядра волоконно-оптический кабель оптического волокна кабеля падения ftth кабель цена

0,01 $ - 0,03 $

Сменный новый подшипник ступицы колеса A2029800016 2029800016 для Mercedes-Benz C124 W124 W201 S202 C208 R170 R129 C124

5,00 $ - 10,00 $

Новый бренд ZXA10 Zte C620 OLT SPUF * 2 + PRAF 10 г, AC XGPON с XFTH SFUL GFGN C ++ плата

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $