DIN 1 2714/55NiCrMoV7 листы нержавеющей стали холодного проката AISI 6F3 ГБ 5crnimov сплав кованые форма для изготовления блоков

- Категория: >>>

- Поставщик: Hunan Qilu Metal Co. Ltd.

Сохранить в закладки 1600535050868:

Описание и отзывы

Характеристики

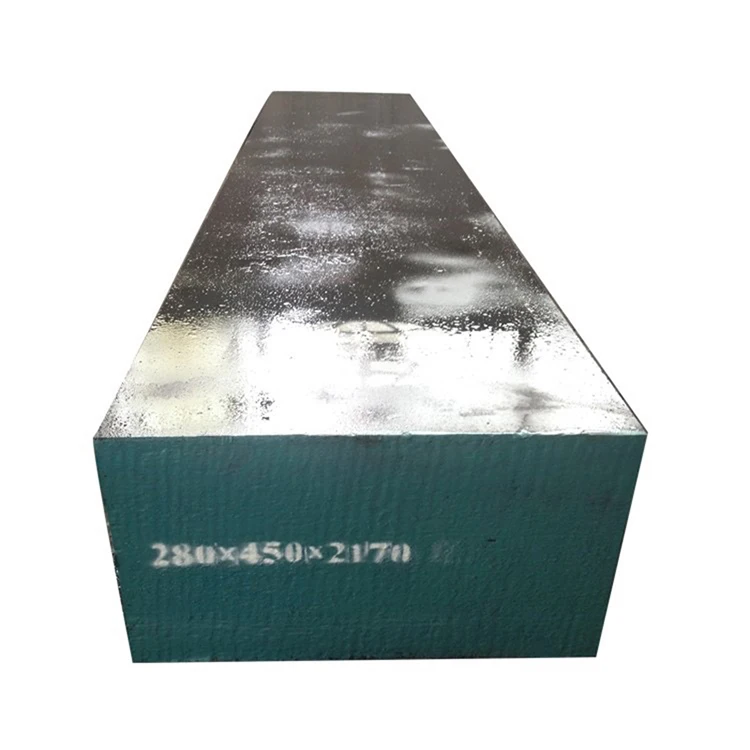

DIN 1.2714/55NiCrMoV7 AISI 6F3 GB 5CrNiMoV Alloy Forged Block Mould Steel

1: DIN 1.2714 steel introduction

DIN 1.2714 is highly recommendable for Close Die Forgings due to its characteristics of high wear-resistance, extra toughness , high hardness which is achieved with Cr-Ni-Mo-V high graded alloys.

DIN 1.2714 tools steel are used in various application such as hot punches, hot shear blades, froging dies, die casting dies, hot gripper dies and extrusion tooling, etc.

2: DIN 1.2714 Steel equivalent

| Country | China | Japan | Germany | USA | UK |

| Standard | GB/T 1299 | JIS G4404 | DIN EN ISO4957 | ASTM A681 | BS 4659 |

| Grade | 5CrNiMoV | 1.2714 | 6F3 |

3: DIN 1.2714 steel chemical composition

| Grade | C | Si | Mn | P | Ni | Cr | V | Mo |

| DIN 1.2714 | 0.50-0.60 | 0.10-0.40 | 0.65-0.95 | 0.03 | 1.50-1.80 | 1.00-1.20 | 0.07-0.12 | 0.45-0.55 |

| ASTM 6F3 | 0.50-0.60 | 0.10-0.40 | 0.65-0.95 | 0.03 | 1.50-1.80 | 1.00-1.20 | 0.07-0.12 | 0.45-0.55 |

4: DIN 1.2714 steel mechanical properties

The mechanical properties mainly include tensile strength, yield strength, elongation, area or reduction, hardness, impact value, non-metalic inclusion etc. Different heat treatment, the mechanical properties will be different, such as normalized, tempered, QT. If you want to know the properties, kindly contact the salesman.

5: DIN 1.2714 steel overviews

| Size | Round | Dia 6-1200mm |

| Plate/Flat/Block | Thickness 6mm-500mm | |

| Width 20mm-1000mm | ||

| Process | EAF+LF+VD+Forged+Heat treatment(optional) | |

| Heat treatment | Normalized ; Annealed ; Quenched ; Tempered | |

| Surface condition | Black; Peeled; Polished; Machined; Grinded; Turned; Milled | |

| Delivery condition | Forged; Hot rolled; Cold drawn | |

| Test | Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. | |

| Payment terms | T/T;L/C;/Money gram/ Paypal | |

| Trade terms | FOB; CIF; C&F; etc.. | |

| Packing | Standard Packages, or as Customers Request | |

| Delivery time | 30-45 days | |

| Application | DIN 1.2714 tool steel are suitable for the cutting tool, cold/heat distortion mould and measuring implements, and further to manufacture the piston, valve, valve seat of fuel pump of diesel engine, Cutting tools, Mechanical parts, Air hammer tools, Piercing tools. | |

6: Heat treatment

The preheating of measuring and cutting tool steel is spheroidizing annealing, final heat treatment is quenching + low temperature tempering and hardness after heat treatment can reach 60~65HRC. When heat treat tool steel grades consideration should be given to hardening temperature, including ratio of heating, cooling and soaking times which will differ due to factors such as the shape and size of each chemical component. Other considerations during heat treatment include the type of furnace, quenching medium and work piece transfer facilities.

7: Features and classifications

Hot-work die divides into several main types, such as hammer forging, die forging, extrusion and die casting, including hot forging die, press machine forging die, stamping die, hot-extrusion die, metal die-casting mould. Heat distortion mould not only supports huge mechanical stress, but also thermal stress during working repeatedly. Hot-work die steel should have not only high hardness, red hardness, abrasion resistance, toughness, but also have excellent high temperature strength, thermal fatigue stability, thermal conductivity, upper harden-ability for guaranteeing the whole cross section with consistent mechanical property.

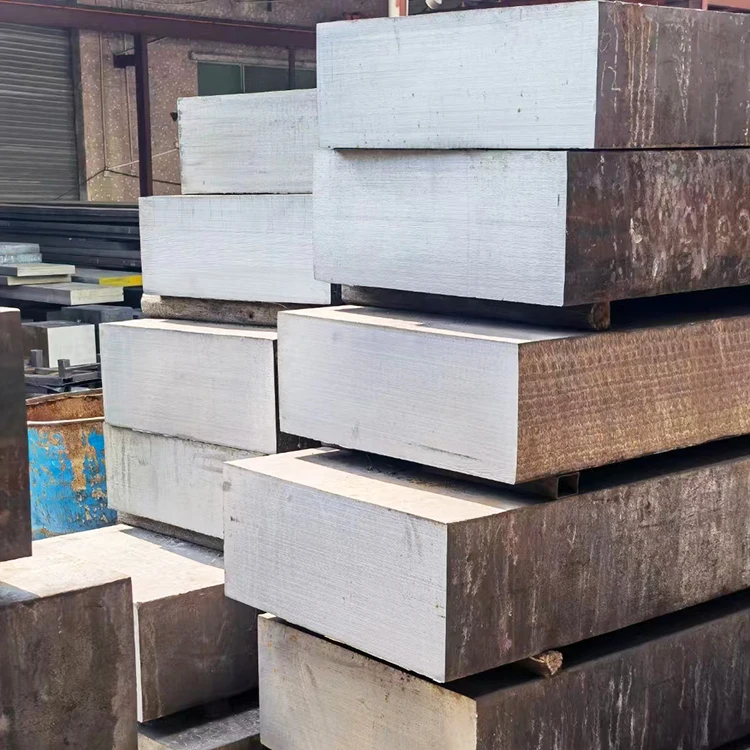

8: Delivery condition

For hot forged or hot rolled bar, usually the delivery condition is hot forged or rolled, annealed, rough turned.

For hot forged plate, usually the delivery condition is hot forged, annealed, milled surface.

For hot rolled plate, usually the delivery condition is hot rolled, annealed, black surface.

Hunan Qilu Metal Co., Ltd has the capacity to forge round steel, steel flat, square steel, module, shaft and roller, etc. The main specifications of the products include Φ80-1000mm forging materials and 80-1200mm square billets and which the maximum piece weight can reach 50T.

Company Main Products:(If you do not find the product you need, please contact us)

Cold Work Tool Steel | DIN 1.2080,DIN 1.2379,DIN 1.2436,DIN 1.2210,JIS SKS3,AISI O2 |

Hot Work Tool Steel | H13,DIN 1.2714,DIN 1.2767,DIN 1.2344(H13),DIN 1.2713 |

Engineering Steel | AISI 1020,AISI 1045,AISI1050,AISI 5140,AISI 4130,AISI 4140(40CrMo4),AISI 4340, DIN 1.5919,AISI 8620,S235JR,S355JR |

Plastic Mould Steel | P20,P20+S,P20+Ni,DIN 1.2083,DIN 1.2316,DIN 1.2085 |

Spring Steel | AISI 9260,AISI 5160,AISI 6150,65MN,55CrMnA |

Stainless Steel | 316L,201,301,304,316,410,420,430,431,440C,SUS630(DIN1.4542) |

High Speed Steel | DIN 1.3343(M2),DIN 1.3243(M35),DIN 1.3247,DIN 1.3265 |

Hunan Qilu Metal Co., Ltd were already engaged in exporting steel for 11 years, could supply a great variety of hot forged, hot rolled and cold drawn Steels, including engineering steel, cold work tool steel, hot work tool steel, plastic mold steel, spring steel, high speed steel, stainless steel etc., besides Qilu Metal also has their own heating treatment shop and machining shop to provide heating and cutting service.

Since 2008 year, Hunan Qilu Metal has the right to export all FORGED STEEL behalf of Qilu Speical Steel Co.,ltd which is specialized in smelting and forging of special steel since 1965 year, now Qilu special steel is one of the biggest manufacturer of forged product in China.The forged products are used in Automotive, Aerospace, Power Generation, Oil & Gas, Transportation and Industrial. We already set up the warehouse in Wuxi and Dongguan city, more than 20000 tons ex-stock could be supplied with kinds of size.

Qilu Metal is the professional one-stop steel manufacturer, stockist and exporter in China, our customers spread all over the world, include West Europe, North America, South America, Asia, Middle Asia, Africa, Australia, etc.

The company owns advanced special steel smelting facilities and forging processing equipments, the main steel-making equipment include 2 sets of 50t ultra-high power electric arc furnaces,2 sets of 60t LF refining furnaces,1 set of 60t vacuum degassing refining furnace and 4 sets of 1-20t electroslag re-melting furnaces.

The main forging equipments mainly include:3 sets of 5t electro-hydraulic hammers, 1 set of high-speed forging units of 800t,1600t,2000t and 4500t respectively.

Q1:Are you trading company or manufacturer ?

We are professional manufacturer for many years. we can provide a wide range of steel products.

Q2:What is alloy steel round bar export packing?

Usually bundling for large diameter,small diameter bars in bulk or as customer's demand.

Q3.What is your MOQ?

We accept small order,if it is stock,any quantities can be accepted.

Q4.What is your lead time?

Depends actual order,around 20-35 days,or negotiation.

Q5.Can you supply sample?

Yes,we can.Sample fee according to your size.

Q6:What certificates do you have?

ISO, ABS, BV, CCS, Dnv, Lr, Gl, Mill Certificate

Q7: How can I get your quotation as soon as possible?

The email and fax will be checked within 24 hours,meanwhile,the Skype,Wechat and WhatsApp will be online in 24 hours.Please send us your requirement,we will work out a best price soon.

Any interests in our company and products, please feel free to contact us for quotation. We warmly welcome you to our factory.

Hunan Qilu Metal CO., LTD

Web: qilumetal.en.alibaba.com

Похожие товары

Генератор азота PSA 99.9995% чистоты для мелкомасштабного завода по производству зеленого аммиака N2

Пневматический ручной пружинный механический клапан SNS (серия MV)

Китайский новый стальной стержень, автоматическая машина для выпрямления проводов, машина для выпрямления арматуры, машина для выпрямления металла

AC220V-240V якорь ротора якоря для DEWALT угловая шлифовальная машина D28111 D28111X D28112 D28112X 28111 28112

Высококачественная 1050D ткань из нейлона Оксфорд для предотвращения разрыва, высокопрочная ткань для огнестойкой одежды

Самая дешевая фабрика 10,1 дюймов Wins10 1,8 ГГц 2 + 64 Гб Водонепроницаемый промышленный Прочный планшет

OKL36110 shaoxing Роскошный домашний текстиль Новый дизайн в наличии синий диван бархатная ткань обивка 3 места оптовая продажа

Новые поступления

Новинки товаров от производителей по оптовым ценам