Пластиковый ящик пластиковые штабелируемые ящики для литья под давлением HS 400

- Категория: >>>

- Поставщик: Hangzhou Dingchuan Import&export Co. Ltd.

Сохранить в закладки 1600539355933:

Описание и отзывы

Характеристики

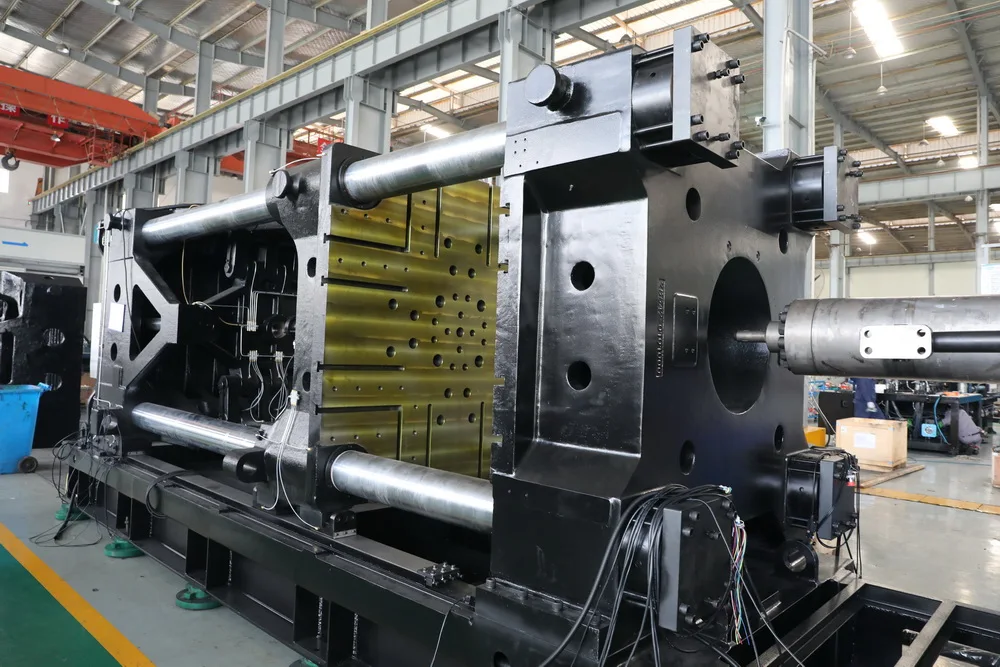

Plastic Crate Stackable Plastic Crates Making Injection Molding Machine HS-400

Agriculture Strong Ventilated Crate Injection Molding Machine 400ton HS-400

USA Plastic Fruit Crates Injection Molding Machine 400ton 500ton 560ton 650ton 850ton

Highshine HS-400 Energy Saving Servo Injection Molding Machine 400ton Contact Expert: Wiki Wong

Wechat/Mobile/Whatsapp +8613738082939

Highshine sero injection molding machines standard configuration

Techmation Q8 control panel and Inovance PLC

Taiwan FOTEK SSR relay

one injector valve

two core pull valve

one air blow

Taiwan Northman direction valve

Digital proportional valve for back pressure

Italy Intermot hydraulic motor

Germany hydraulic hose

stainless steel cover for barrel

double linear rail

3 safety locks: switch, mechanical and hydraulic

Highshine HS-400 400ton servo plastic crates injection molding machine

Japan Mitsubishi and Taiwan Tali CNC for making high precision casting parts, platen and bushing to ensure injection unit, clamping unit and screw work smoothly without any problem during long time operation.

| international specification | 2700 | |||

| Unit | Injection Molding Machine Model: HS-400 | |||

| Injection Unit | ||||

| screw diameter | mm | 68 | 76 | 84 |

| theoretical hot volume | cm3 | 1198 | 1497 | 1829 |

| shot weight(PS) | g | 1091 | 1362 | 1664 |

| length/diameter ratio | L/D | 22.4 | 20.0 | 20.0 |

| injection pressure | Mpa | 225 | 180 | 147 |

| injection rate ps | g/s | 303 | 378 | 462 |

| injection stroke | mm | 330 | ||

| screw speed | rpm | 168 | ||

| Clamping Unit | ||||

| clamping force | ton | 400 | ||

| max. daylight | mm | 1460 | ||

| clamping stroke | mm | 710 | ||

| distance between tie bars | mm | 760*710 | ||

| min. mould dimension | mm | 530*500 | ||

| mould thickness range | mm | 240-750 | ||

| ejector force | ton | 11.1 | ||

| ejector stroke | mm | 210 | ||

| no. of ejector pins | pcs | 13 | ||

| system pressure | Mpa | 17.5 | ||

| General Unit | ||||

| major motor | kw | 50 | ||

| no. of heater zones | unit | 5+1 | ||

| heater input power | kw | 27/31 | ||

| oil tank capacity | liters | 590 | ||

| net weight | ton | 15.8 | ||

| machine dimension(L*W*H) | m | 7.45*1.71*2.25 | ||

| Highshine Injection Molding Machine Other Models | ||||||

| Model | tie bar distance (mm) | B screw injection weight(g) | clamping force (KN) | machine weight(ton) | machine size (L*W*H, m) | |

| HS-110 | 110ton | 410*360mm | 153g | 1100KN | 3.5ton | 4.1*1.25*1.7m |

| HS-150 | 150ton | 460*410mm | 229g | 1500KN | 4.4ton | 4.7*1.35*1.8m |

| HS-180 | 180ton | 520*470mm | 326g | 1800KN | 5.4ton | 5.2*1.45*1.9m |

| HS-240 | 240ton | 580*530mm | 447g | 2400KN | 7.5ton | 5.6*1.65*2m |

| HS-270 | 270ton | 620*570mm | 682g | 2700KN | 8.4ton | 6.2*1.55*2.1m |

| HS-320 | 320ton | 710*670mm | 975g | 3200KN | 13.4ton | 6.8*1.65*2.2m |

| HS-400 | 400ton | 760*710mm | 1362g | 4000KN | 15.8ton | 7.45*1.71*2.25m |

| HS-500 | 500ton | 830*810mm | 1866g | 5000KN | 19.5ton | 8.23*1.78*2.3m |

| HS-560 | 560ton | 860*840mm | 1866g | 5600KN | 24ton | 8.53*1.82*2.45m |

| HS-650 | 650ton | 930*930mm | 2541g | 6500KN | 29.5ton | 10.5*2.28*2.75m |

| HS-850 | 850ton | 1080*1000mm | 3431g | 8500KN | 40ton | 11.45*2.43*2.85m |

| HS-1000 | 1000ton | 1160*1160mm | 4502g | 10000KN | 50ton | 12.4*2.53*2.78m |

| HS-1200 | 1200ton | 1250*1250mm | 5770g | 12000KN | 58ton | 12.6*2.72*2.88m |

| HS-1400 | 1400ton | 1450*1350mm | 7621g | 14000KN | 75ton | 13.8*3.12*2.9m |

| HS-1600 | 1600ton | 1560*1430mm | 7621g | 16000KN | 90ton | 14.5*3.35*2.9m |

| Highshine servo injection molding machines main parts brand | |||

| Parts Name | Brand | Orign | Remark |

| plasticizaion motor | DANFOSS | Denmark | Limited cycloid motor |

| air switch | SCHNEIDER | China | |

| AC magnetic contactor | SCHNEIDER | China | |

| thermal relay | SCHNEIDER | China | |

| solid state relay | Fotek | Taiwan | |

| intermediate realy | SCHNEIDER | China | |

| linear transducer | Gefran | Italy | |

| computer controller | Techmation | Taiwan | |

| high pressure hose | Alfagoma | Italy | |

| screw | 38CrM0A1A | China | |

| casting | QT500-7 | China | |

| tie bar | 40Cr | China | |

| oil sealing | NOK | Japan | |

| Highshine HS Series Injectoin Molding Machine Free Accessories | ||||

| Item | Specification | Quantity | Unit | Remark |

| solid state relay | SSR-40A | 2 | pcs | |

| Electric heating ring | φ36*40L 150W | 2 | pcs | |

| Electric heating ring | Φ36*60L 200W | 2 | pcs | |

| Thermocouple (screw type) | 1/4 ″ 2.5M | 2 | pcs | |

| L-shaped hexagon wrench | 14m/m | 1 | pcs | |

| adjustable wrench | 300(12″) | 1 | pcs | |

| Wrenches | 24-27 | 1 | pcs | |

| Allen wrench | 1.5-10 | 1 | pcs | |

| Phillips screwdriver | 6″ | 1 | pcs | |

| Slotted screwdriver | 6″ | 1 | pcs | |

| Plastic bag | 8*1.7*2.2 | 1 | pcs | |

| Plastic tool box | 25 | 1 | pcs | |

| leveling pad | φ200 | 10 | pcs | |

| mold clamp | BT16-130 | 8 | pcs | |

| Grease gun | 1 | pcs | ||

| Double-cut nozzle D3 | SKD61 standard:HD400 | 2 | pcs | |

| Extended nozzle holder | SKD61 standard:HD400 | 2 | pcs | |

| Funnel shutter | UN200-C-207-00 | 2 | pcs | |

| Socket head cap screws | M16*80(high strength) | 16 | pcs | |

| Electric cabinet door lock key | K3 with MS705-3 | 2 | pcs | |

To serve the market with high quality, to meet the needs of customers in the industry, on the basis of inheriting the well-known brand " TUP ", enriched the factory product line; Bakelite injection molding machine, rigid PVC powder injection machine and other products, and actively develop the physical foam injection molding machine and all-electric injection molding machine as the main follow-up development.

On the basis of inheriting Taiwan Liansu well-known brand T.U.P., the company has been adhering to the " technology-based, speed to win " spirit of enterprise, as well as " quality, service, innovation " business philosophy, inheritance and development of Taiwan Liansu advanced machinery manufacturing technology to promote management innovation to enhance core competitiveness, In the commitment to create infinite wealth and future for customers at the same time, to create a green intelligent equipment of modern enterprises!

Похожие товары

Воздушный компрессор для цементного грузовика с длительным сроком службы 132кв

OEM механическое уплотнение типа AL68D для производства водяных насосов Alfa Laval, стальные уплотнения на заказ

GENZO 8/10 дюймов Intel Джаспер N5100 прочный автомобильный планшет с RJ45 и RS232 и GPS антенна прочный транспортных средствах планшет

Оптовые производители, плетеная прочная медная шина 3000А 280а для новой энергетической промышленности

Коммерческое холодильное оборудование для супермаркетов, ресторанов, Раздвижная стеклянная дверь, deli, холодильник, витрина, холодильник

Pgi кровельный лист длинного диапазона цвета 30 Калибр гофрированная сталь защита от дождя ребра тип лучшая цена оптовая продажа от производителя

Запуск X431 CRP129E obd2 Профессиональный диагностический инструмент с функцией сброса 5 CRP129 obd 2 eobd считыватель кодов

Новые поступления

Новинки товаров от производителей по оптовым ценам