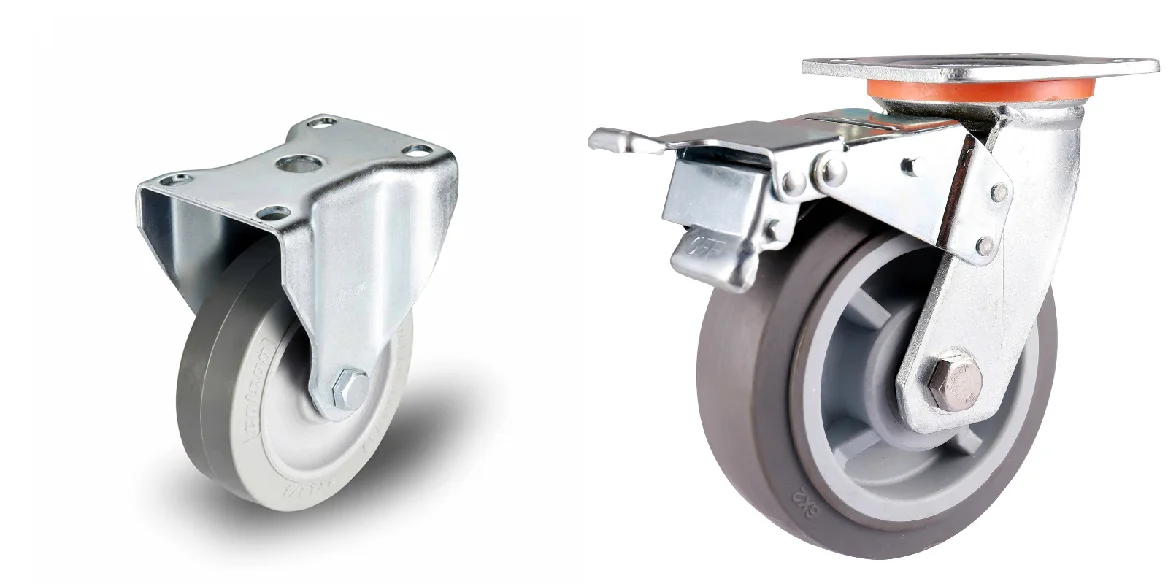

Багажные колеса из термопластичной

- Категория: TPR >>>

- Поставщик: Zhejiang Lanboom Rubber And Plastic Co. Ltd.

Сохранить в закладки 1600540273948:

Описание и отзывы

Характеристики

| Introduction |

TPR material, Thermo-plastic-rubber material, means thermoplastic Rubber material. Is a kind of elastic rubber without vulcanization, can be directly processed (such as injection molding, extrusion, blow molding, etc.) thermoplastic soft rubber.

TPR material is based on thermoplastic styrene butadiene rubber (such as SBS, SEBS) as raw materials, adding resin (such as PP,PS), filler, plasticizer oil and other functional additives blend modified materials.

TPR, this is the name of thermoplastic elastomer for most users, and this kind of elastomer mainly refers to styrene elastomer SBS,SEBS modified materials. In order to distinguish TPR material suppliers, the elastomer material modified by SBS base material is called TPR, while the material modified by SEBS is called TPE. But actually TPE is a broad concept, including styrene elastomer SEBS,SBS modified materials, also including TPU,TPV,TPEE,TPO and other elastomer materials.

| Characteristics |

Rubber has excellent resilience, wear resistance, skid resistance and shock absorption performance. TPR material is superior to rubber in soft comfort, but it is inferior to vulcanized rubber in tensile strength, fatigue resistance and mechanical properties.

Generally speaking, TPR material is based on SBS base material, and its chemical properties are as follows: weather resistance, aging resistance, temperature 70~75℃. If the material with good aging resistance and temperature resistance is needed, the modified material of SEBS base material can be selected.

| Application |

TPR materials are widely used in daily products, adult products, hardware tools, luggage wheels, sports equipment, toy products, auto parts, medical products, wire and cable, electronic appliances, communication instruments and shoe products and so on. Among them, shoe material and toy industry is mainly applied to TPR of SBS base material, and SEBS modified material is mainly applied to products with aging resistance, weather resistance, high material physical tensile strength requirements, and ultra-low material hardness (lower than 5 degrees Shore hardness).

| Features |

- Hardness characteristics: TPR material can be adjusted at shore hardness of 5~100 degrees, and the modified material based on SEBS can be adjusted to a lower hardness.

- Processing characteristics: TPR material and some glue, ink and other good adhesion performance, with good oil injection silkscreen processing.

- Environmental characteristics: TPR material as environmental soft adhesive, the main hazardous substances such as plasticizer Phthalate, nonylphenol NP, PAHs detection, in line with ROHS,REACH,EN71-3, ASTMF963 environmental detection standards.

| Physical Properties |

Take CP65906 as an example, other brands number of TPE/TPR/TPV can be tested according to your requirement.

TPE CP65906 series is a kind of soft thermoplastic elastomer (TPS) based on styrene copolymer, which has good physical and chemical properties.

| Photo show |

| Packaging |

| Storage |

- Store in a cool, dry and well ventilated area to avoid direct sunlight;

- Keep away from incompatible fire sources and heat sources to avoid direct rain wetting;

- Store in suitable, moisture-proof double-layer bags.

| About us |

Lanboom is a 15-year experienced company in rubber & plastic raw materials, related extrude & injection products manufacturing, developing and marketing. Lanboom has been investing 30% of annual profit for products research and development.

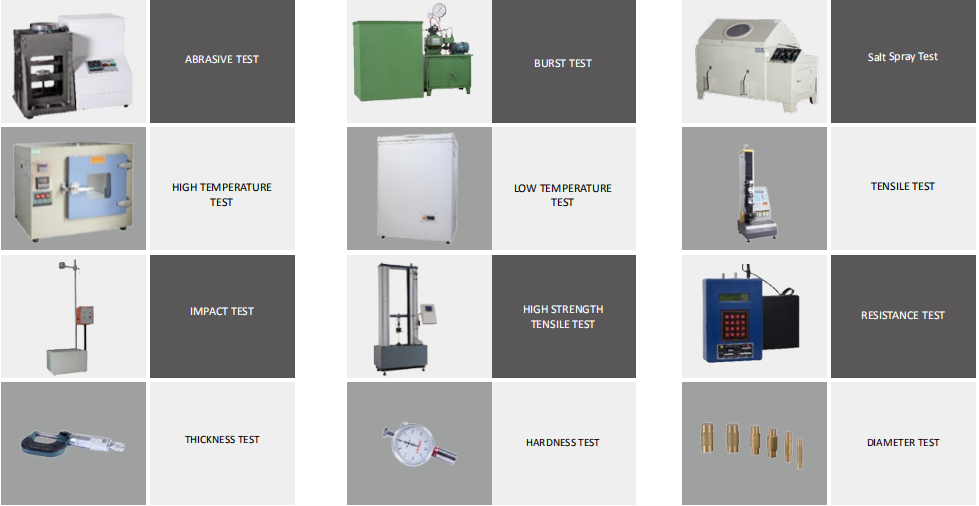

We have passed ISO9001 and TS16949 quality control system, with more than 60 test equipments of 24-hour monitoring as the ISO/ASTM standards. All products have been insured by China Taiping , and Lanboom products are sold to more than 20 countries across America and Europe.

We will constantly pursuit "customer first" principle and provide customized products.

| Testing Equipments |

| Main Certificates |

| FAQ |

Q : Are you a factory or trading company?

A : We are a professional rubber & plastic raw materials manufacturer in Dongyang, Zhejiang, China.

Q : Do you have laboratory in company?

A: Yes, we have 2 laboratory centers which conduct all deferent tests as customer required, like properties, life time etc.

Q : What's your factory's production capacity?

A : 6,000 tons/year.

Q: What is the shipping port?

A: Ningbo port, China.

Q: Do you support OEM /ODM?

A: Yes, we can do customized products according to your request.

Q: What about your after-sales services?

A: 1 year warranty for all kinds of products.

Похожие товары

Tpe гранулы tpr сырье термопластичные

TPR настраиваемый гранулированный мягкий составной сырьевой материал

Настраиваемая TPR гранулированная оксигенераторная маска кислородно-Кремниевая дышащая сырьевая

Высококачественное сырье ТПЭ термопластичные эластомерные гранулы с

TPR гранулы для подошвы обуви/термопластическая

Высокое качество сделано в Тайване Китай прочные экструзионные резиновые детали для промывки Oem общей

Поставка термопластичных эластомерных резиновых гранул TPE TPR TPU TPV Tpee пластиковые гранулы

Новые поступления

Новинки товаров от производителей по оптовым ценам