Химическая гипсокартонная печь роторная машина для обжига порошка

- Категория: Cement Making Machinery >>>

- Поставщик: Gongyi Derui Machinery Co. Ltd.

Сохранить в закладки 1600547891527:

Описание и отзывы

Характеристики

gypsum powder rotary kiln

Product introduction and application

The rotary kiln produced has advanced structure. It can effectively improve preheating effect with its low resistance vertical preheater. After the material is preheated, the feeding decomposition rate can reach 20%-25%, thus can directly make use of 10-15mm fine fraction materials. The reliable airtight two-ends combination squama make the air leakage factor under 10%. The usage of compound refractory reduces radiation loss.Rotary kiln belongs to building material equipment, which can be divided into cement kiln,metallurgy chemical kiln and lime kiln according to different materials.

Working Principle of rotary kiln

The rotary kiln can be divided into cement kiln, metallurgy chemical kiln and lime kiln according to the different materials processed. The cement kiln is mainly used to calcine cement clinker; In the process of non-ferrous and ferrous metallurgy, such as iron, aluminium, copper, zinc, stannum, nickel, wolfram, chromium, etc., the rotary kiln can be used to sinter and roast ore, concentrate, intermedium, etc.; The lime kiln is mainly used to calcine limestones.

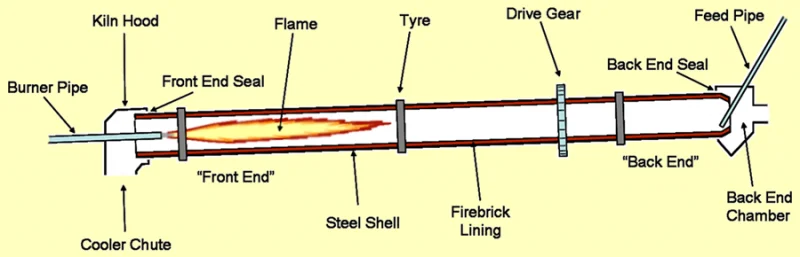

The Rotary kiln is mainly composed of kiln shell, refractory bricks, supporting device, supporting device with catch wheel, transmission device, lubrication device, mobile kiln head and sealing device at the end of the kiln.

1. Supporting device: advanced shaft structure, automatic temperature measuring device and electrical heating.

2. Catch wheel: including two kinds mechanical wheel and hydraulic pressure.

3. Gears: single or double. Control the rotating speed by buncher, DE machine and frequency variable motor. Be reliable, energy-saving, and efficient.

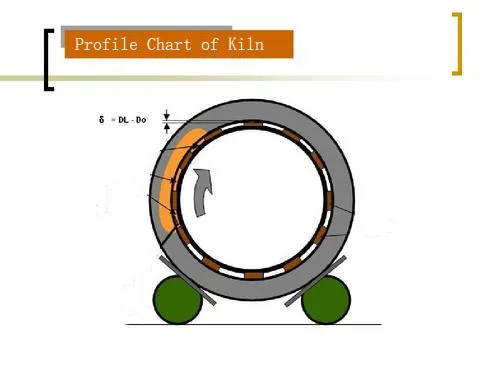

4. Kiln shell tire bolster: lower bolster has three types: fixed, zoom and floating. The structure is simple, replacement is convenient and won’t hurt cylinder.

5. Sealing equipment: there are many kinds for choice according to kiln models, including air cylinder edge sealing, spring edge sealing, and graphite block sealing and combination for above. The sealing effect is very good.

6. Kiln head hood: including stationary type and flexible type.

Model(m) | Diameter (m) | Length(m) | Slope(%) | Capacity(t/h) | Rotate Speed (r/min) | Motor Power(kw) | Weight(T) |

φ1.4×33 | 1.4 | 33 | 3 | 0.9-1.3 | 0.39-3.96 | 18.5 | 47.5 |

φ1.6×33 | 1.6 | 33 | 4 | 1.2-1.9 | 0.26-2.63 | 22 | 50 |

φ1.6×36 | 1.6 | 36 | 4 | 1.2-1.9 | 0.26-2.63 | 22 | 52 |

φ1.8×32 | 1.8 | 32 | 4 | 1.9-2.4 | 0.16-1.62 | 30 | 78.2 |

φ1.8×45 | 1.8 | 45 | 4 | 2.8-3.34 | 0.21-2.11 | 30 | 95.2 |

φ1.9×36 | 1.9 | 36 | 3.5 | 1.2-1.7 | 0.29-2.93 | 30 | 86.3 |

φ1.9×45 | 1.9 | 45 | 3.5 | 1.65-2.5 | 0.29-2.93 | 37 | 109 |

φ2.2×48 | 2.2 | 48 | 3 | 1.9-2.1 | 0.98-2.93 | 55 | 141 |

φ2.5×40 | 2.5 | 40 | 3.5 | 6.0-7 | 0.44-2.44 | 55 | 139.61 |

φ2.5×50 | 2.5 | 50 | 3.5 | 7.0-8.0 | 0.48-1.44 | 55 | 179.6 |

φ2.5×54 | 2.5 | 54 | 3.5 | 8.0-8.6 | 0.48-1.44 | 55 | 196.29 |

φ2.7×42 | 2.7 | 42 | 3.5 | 10.0-11.0 | 0.10-1.52 | 55 | 198.5 |

φ2.8×44 | 2.8 | 44 | 3.5 | 11-12.5 | 0.80-2.39 | 55 | 198.6 |

φ3.0×45 | 3 | 45 | 3.5 | 13.3-16.9 | 0.5-1.35 | 55 | 223 |

φ3.2×52 | 3.2 | 52 | 3.5 | 16-18.5 | 0.48-2.44 | 110 | 278 |

Pre-sale services,we do

Act as a good adviser and assistant of clients; enable them to get rich and generous returns on their investments;

1. Select equipment model;

2.Sdeign and manufacture products according to clients' special requirement;

3. Train technical personnel for clients.

Services during the sale,we do

Respect clients; devote ourselves to improving the total value of clients.

1. Pre-check and accept products ahead of delivery;

2. help clients to draft solution.

After-sales service,we do

Provide considerate services to minimize clients' worries.

1. Assist clients to prepare for the first construction scheme;

2. Install and debug the equipment;

3. Train the first-line operators on site;

4. Examine the equipment regularly;

5. Take initiative to eliminate the troubles rapidly at site;

6. Distribute the guarantee fittings door-to-door;

7.provide perfect service;

8. Provide technical exchanging;

9. Provide maintenance for big items.

Gongyi Derui Machinery Co., LTD entered the mechanical industry from the beginning of the 1980’s, earlier than most factories. With the company philosophy these years, our products are sold to many customers from home and abroad, popular in India, Russia, Kazakhstan, Africa, South America, Mid-East, Southeast Asia, and almost 30 countries and areas. And it is our honor to make a contribution of to the development of these countries.

Growth is only a process, and the brilliance is the new beginning. In order to respond positively to the good policy of The Belt and Road, we will, as always, provide higher and higher quality products and service, to win more and more acclamation and respect for Chinese national industry. Review ourselves with serious attitude, and win the trust with excellent quality. We sincerely hope to take win-win cooperation with entrepreneurs and companies all over the world, to develop the market together.

Похожие товары

Высококачественная сушилка sprey для потока воздуха от производителя

Конкурентоспособная цена, производственная линия роторной сушилки нефтяного кокса

Хорошая поставка нефтяного кокса, кальцинированная Вращающаяся печь, цена

Малый нефтяной кокс известняк Вращающаяся печь для продажи

Захватывающая цена, нефтяной кокс, Вращающаяся печь, технический чертеж

Экологическая машина для обжига нефтяного кокса

Мировая широко используемая бокситовая кальцинированная нефтяная Коксовая роторная печь

Новые поступления

Новинки товаров от производителей по оптовым ценам