PIRALU

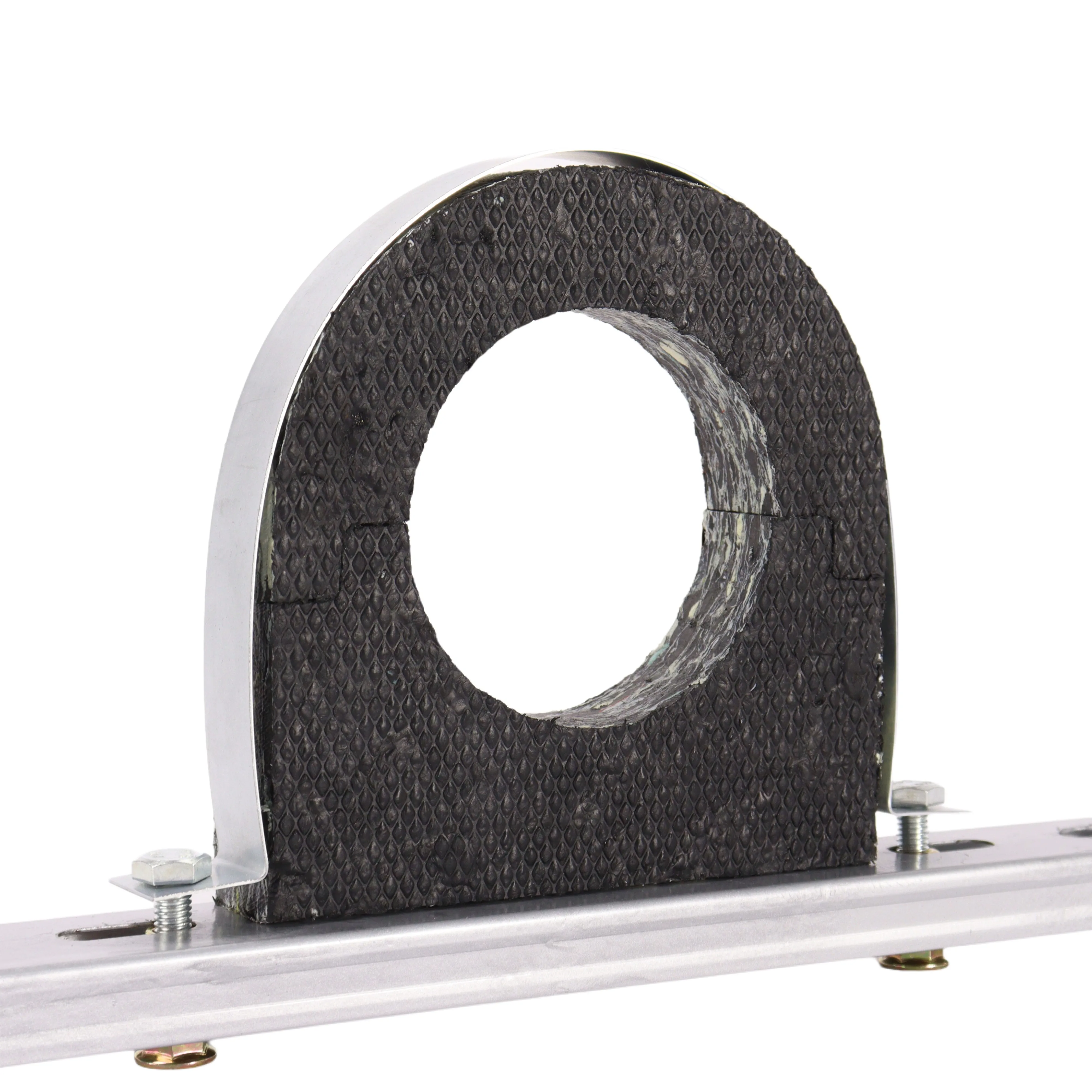

PIRALU Pre-Insulated duct system is an innovative technology for ACMV ductwork, the rigid polyisocyanurate panel is used as an alternative of traditional GI for operation such as fresh air, supply, return and exhaust air ductwork for ACMV system.

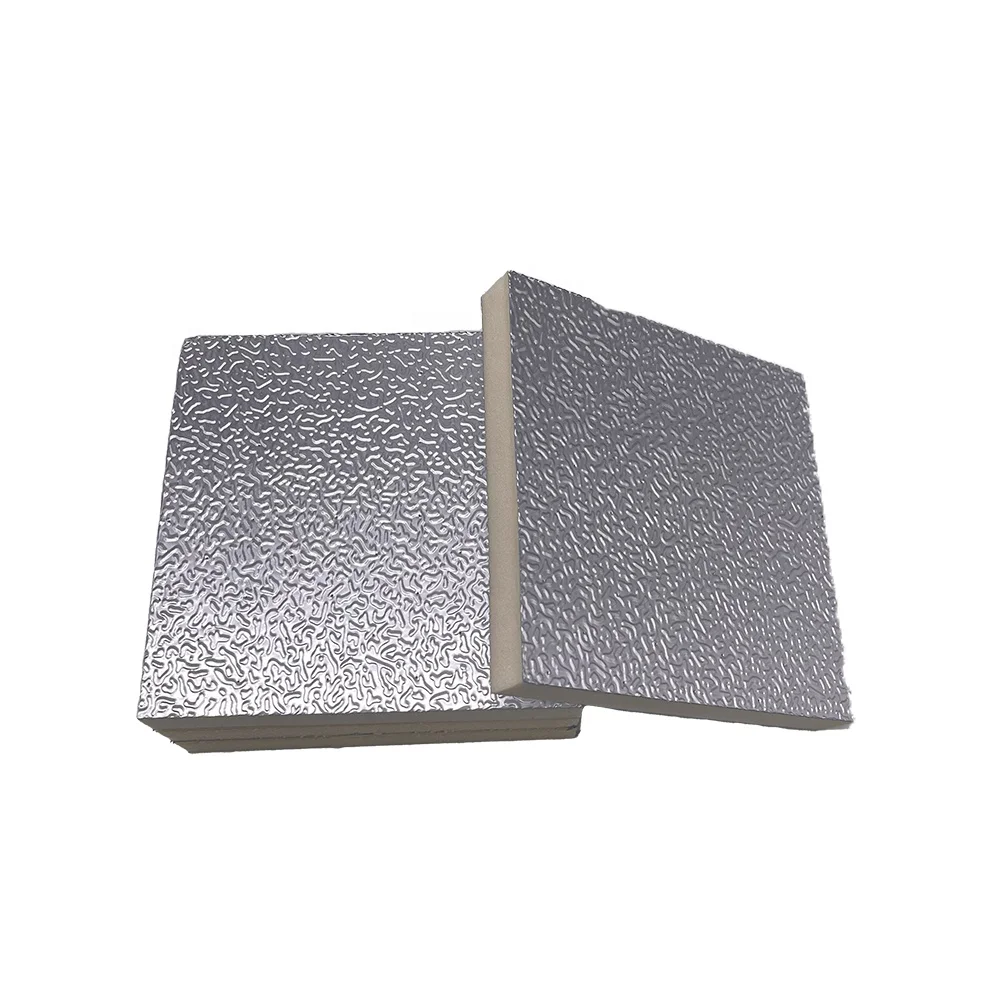

These panels feature a unique sandwich construction that is the result of injecting polyisocyanurate(PIR) as the core material laminated with aluminum facing on both sides. These panels are suitable for the construction of air distribution ducts in air-conditioning and heating systems.

The material's main characteristics are: superior thermal K value, a high level of rigidity and lightness, extremely easy to handle and install.

PIRALU Pre-Insulated Duct System is specially developed for use in residential, commercial and industrial units of ACMV duct system to satisfy the thermal, airflow, fire and easy to installation requirement.

PIRALU Pre-Insulated Ducting System is the first Singapore Green Building Council certified pre-insulated duct product, which reflects our product performances, efficiency, and environmentally friendly aspects. The panel also conforms to class 0 rating and has been certified by TÜV SÜD PSB. PIRALU Pre-Insulated Duct System protects the surface from the spread of flames and limits the amount of heat released from the surface during a fire.

A rigid polyisocyanurate (PIR) foam panel coated on both sides with embossed aluminium. Given the thickness of the aluminium sheet (>50 µm), it is considered as a vapour barrier.

Closed polymer cell structure and the aluminium coating prevents water absorption.

Excellent thermal conductivity coefficient.

Easy to handle, cut and assemble.

Ten-lead Thermal insulation:

tees low thermal conductivity and limit the risk of condensation.

constant and continuos in all duct sections. Special closed-cell insulation guaran Friction loss: the low number of flanges and limited surface roughness keep linear friction losses at very

low levels.

Airtight seal: airtightness of ten-lead ductal ducts is eight times more than traditional ducts

Energy saving: perfect thermal insulation and optimum airtight seal allow for maximum exploitation of air handling unit capacity, increasing efficiency and reducing operating costs.

Hygiene and air quality: the use of aluminium for the internal surfaces of the ducts ensures hygiene andcleanliness. The problem of ageing of the insulation and consequent release of particles is non-existent.

Safety: ten-lead ductal ducts have a low participation in fire, do not drop and smokes have a reduced opacity andtoxicity. ten-lead ductal is in conformity with the requirements of the most restrictive international regulations.

Light weight: the very light weight allows a reduction of weight on the structures, supporting points,

workmanship costs and materials necessary for the installation.

Silent operations: the sandwich structure (aluminium – insulating material – aluminium) guarantees a good acoustic behaviour. Vibration and reverberation are stopped by the insulating material, contributing to a higher comfort in the environment where ten-lead ductal is installed.

Duration: the outer aluminium coating coupled with the insulating material provides sturdiness, rigidity and good resistance to corrosion, erosion and deformation even in special applications.

Construction easiness: possibility of manufacturing ducts in the work shop or directly at job site with considerable advantages on transport costs

![photobank (12)]()

![photobank (70)]()

![photobank (90)]()

![HTB1reSxeUuF3KVjSZK9q6zVtXXa8.jpg]()