Машина для распыления масла плотности 450 650 кг легкая машина производства аэрированного бетона автоклавируемая полная линия блоков AAC

- Категория: >>>

- Поставщик: Zhengzhou Bona Enterprise Co. Ltd.

Сохранить в закладки 1600548526761:

Описание и отзывы

Характеристики

Product Overview

Oil Spraying Machine for density 450-650kg light weight Aerated concrete Autoclaved full line AAC block making machine

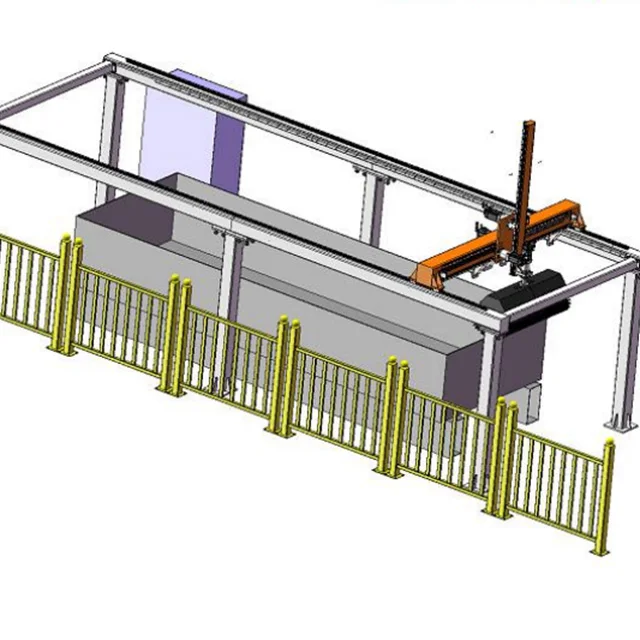

JSY automatic oil brushing machine is a 5-axis linkage servo-controlled automatic oil brushing robot developed by Bona Enterprise, it is mainly used for brushing mould release oil (release agent) to the mould in the oiling station of aerated concrete block production line. The machine automatically compensates the positioning angle and position of oil brushing after internal calculation to ensure the uniform brushing of mold release oil on 5 or 4 sides of the moldbox to form a good isolation and lubrication, so as to realize the smooth release of the blank and ensure the smooth and undamaged products.

JSY automatic oiling machine has a simple and generous appearance, automatic and precise control, clean,environmental friendly oiling process, simple operation and maintenance, and can effectively reduce labor intensity. It can effectively reduce labor intensity and labor cost, it is a high-quality supporting equipment for aerated concrete production line.Oil Spraying Machine for 100000m3 AAC block plant AAC block making machine production line

THE SCENE PICTURES

PRODUCT PARAMETERS

Equipment model | JSY1.0 |

Voltage | AC380V 50HZ |

Whole power | 4.5KW |

Heating power | 3KW |

Working temperature | 50℃ |

Working medium | Demoulding oil |

Release rate | 100% |

PERFORMANCE ADVANTAGES:

1/Stable Structure & Smooth Transmission

a/The equipment frame adopts frame structure;

b/Each moving shaft adopts rack drive and uses double linear guide rail as movement guide;

c/Smooth operation & long service life of mechanical parts;

c/Smooth operation & long service life of mechanical parts;

2/Five Axis Linkage & Precise Movement

a/The compound movement mechanism is composed of a transverse device, a lifting device and a brush oil device, and drives the combined roller brush to reciprocate along XYZ three axes. At the same time, the combined roller brush can rotate around the vertical axis and the two sets of parallel roller brushes can rotate.

b/The moving part is controlled by servo motor, and the error is within 1MM to ensure that the coating is uniform and all aspects are covered.

3/Simple Operation & High Degree of Automation

a/Touch screen human -machine interconnection interface intuitive and clear operation is easy.

b/Fully automated program operation.

4/Modular Design & Easy Maintenance

Adopt a modular assembly process, key components and key positions can be disassembled separately to achieve fast installation and maintenance.

5/Custom-made Roller Brush & Durable

a/Professional custom-made industrial roller brush;

b/Brush hair direction and density has been repeatedly tested, the brush filament

is firmly installed, the material is wear-resistant and pressure-resistant, not easy to stick, long life;

is firmly installed, the material is wear-resistant and pressure-resistant, not easy to stick, long life;

c/The roller brush is easy to disassemble design, easy and quick to replace.

6/Environmental Protection & Safety without pollution

a/Adopts the roller brush oiling method, no dripping & no oil emission outside the

mold box during operation;

mold box during operation;

b/Reduces the dispersion of oil particles in the air, and the on-site operating environment

fully meets the environmental protection requirements.

fully meets the environmental protection requirements.

7/High adaptability

a/No special requirements for the quality of release oil, can adapt to all the release oils used in the market;

b/Can match most of the production equipment, very adaptable.

Main Configuration:

JSY-1.0 truss type automatic oil brushing machine is the first generation of product developed by our company after full market research and expert demonstration, which can meet the existing demand of aerated concrete market for demoulding and oil brushing, and will continue to follow up and iterate and upgrade the product according to the market demand.

JSY-1.0 truss type automatic oil brushing machine is mainly composed of four parts: mechanical part,

electrical control system, oil supply system and positioning system, etc. The specific configuration of the

equipment is shown in the following table.

JSY-1.0 truss type automatic oil brushing machine is the first generation of product developed by our company after full market research and expert demonstration, which can meet the existing demand of aerated concrete market for demoulding and oil brushing, and will continue to follow up and iterate and upgrade the product according to the market demand.

JSY-1.0 truss type automatic oil brushing machine is mainly composed of four parts: mechanical part,

electrical control system, oil supply system and positioning system, etc. The specific configuration of the

equipment is shown in the following table.

JSY-1.0 Automatic oil brushing machine configuration list | ||||||

Name | Qty/set | Confirmation parameters | Remark | |||

Truss track assembly | 1 | Traveling axis servo power 1.3kw | Conventional 7m (applicable 4.8m, 4.2m (applicable to 4.8m, 4.2m mold box, 6m mold box needs to be customized) | |||

Traversing device | 1 | Traversing axis servo power 0.85kw | ||||

Lifting device | 1 | Lifting axis servo power 0.85kw | ||||

Oil brushing device | 1 | Rotary axis servo power 0.85kw Hair roller drive power 0.4kw | ||||

Oil supply system | 1 | Including 400L demoulding oil tank, oil supply pipeline fittings,etc. | ||||

Guide rail automatic lubrication system | 1 | Including automatic lubrication pump and volumetric distributor connector, etc. | ||||

Heater | 1 | 3kW | Steam heating method Electric heating method | |||

Temperature control instrument control cabinet | 1 | |||||

Mold positioning device | 1 | |||||

Electric control system | 1 | Including PLC control system and servo drive drive, etc. | ||||

INSTALLATION CASE

Oil Spraying machine for AAC Block machine Aerated Concrete production line equipment plant

PACKAGES & DELIVERY

COMPANY PROFILE

Zhengzhou Bona Enterprise Co., Ltd. overseas business department of Henan machinery design and research institute, an independent medium-sized company with profound experience in mechanical engineering is a leading supplier of technology to the forming industry since its foundation in 1958 and has been offering special solutions for the manufacture of building materials for some decades now.

High quality after-sales service let you have no worries!

High quality after-sales service let you have no worries!

1. We have a professional and experienced technical team, and ensure a stable and sufficient supply of corresponding accessories.

2. We have strict management system and visit our customers regularly.

3. We have a sound training system to improve the technical needs of customers.

3. We have a sound training system to improve the technical needs of customers.

FAQ

Q1: How many molds can be brushed in 1ton of molding oil?

A1: Can brush about 380pcs mold (6 meters mold)

Q2: How long do each mold brush oil?

A2: 90s-100s/ mold (speed can adjustable)

Q3: How much do each mold is used?

A3: 2L oil/mold

Q4: How’s the volume & packing?

A1: Can brush about 380pcs mold (6 meters mold)

Q2: How long do each mold brush oil?

A2: 90s-100s/ mold (speed can adjustable)

Q3: How much do each mold is used?

A3: 2L oil/mold

Q4: How’s the volume & packing?

A4: 15CBM/ set for one 20GP

Q5: How's the warranty?

A5: One year

ELSE PRODUCTS

Похожие товары

Набор из 2 серверов для свадебных и ресторанных салатов из матового золота, ложка и вилка

Cnc канавочный резец для экскаватора N123H2-0400-0004-TF 4325 LENGTHL1 = 24,84 мм токарный инструмент машина для нарезания канавок

14,20 $ - 14,58 $

Автоматический автомобильный пульт дистанционного управления места для стоянки Электрический барьер управлением с Парковочный замок

26,00 $ - 27,25 $

FAW box грузовой автомобиль 4x2 мини-Фургон Грузовик

25 000,00 $

Компрессор переменного тока MSC90T для Mitsubishi Fuso Canter Rosa Bus и Truck MSC90TA CO107

Резиновый шланг 193-2781 1932781 для CAT E330C, шланг для турбокомпрессора двигателя

Tweezerman Cuticle Scissors Model No 1 by Zabeel Industries

Новые поступления

Новинки товаров от производителей по оптовым ценам

Высокое качество Sunpal 450W-600W 48V фотоэлектрические солнечные панели 500W 500Wp 600W заводская цена с белой задней простыней

0,28-0,32 $

2025 руиба новый продукт зажим для пуповины оптовая продажа медицинский стерильный одноразовый пластиковый

Оптовая продажа индивидуальные синие 3-слойные одноразовые маски для лица хирургические медицинские защитные взрослых

40-41,80 $

Съемная пластиковая ручка штукатурка строительный инструмент для отделки бетона с помощью меток

SHIDU U30 двойной беспроводной Перезаряжаемый Профессиональный UHF микрофон караоке с

39,90-57,40 $

1688 закупка Taobao дропшиппинг агент по покупке онлайн-покупки Китай в Испания Румыния Литва от двери до ddp servic

1 $

OEM стираемая зеленая пластиковая клипса с держателем для ручки магнитная футбольная тренировочная

2-2,80 $