Смеситель с подогревом для полимеров/Электрический смеситель из эпоксидной смолы

- Категория: >>>

- Поставщик: Weihai Chem-Equip Machinery Co. Ltd.

Сохранить в закладки 1600548749209:

Описание и отзывы

Характеристики

Product Description

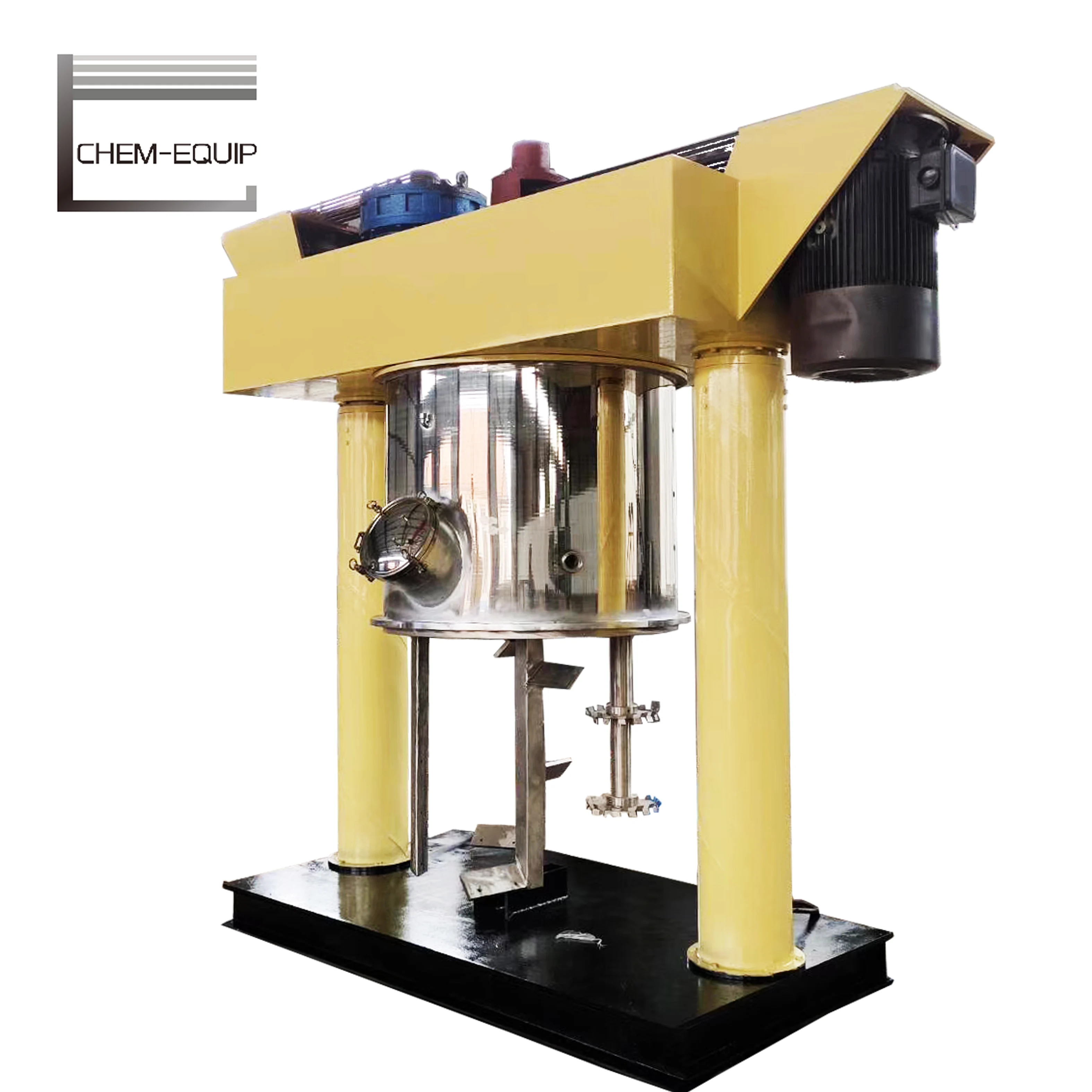

A Double Planetary Mixer includes two blades that rotate on their own axes, while they orbit the mix vessel on a common axis. The blades continuously advance along the periphery of the vessel, removing material from the vessel wall and transporting it to the interior, sometimes an adaptive scraper is assembled for cleaning material sticking on barrel wall.

Applications

* Glue Industrial: Sealant, Hot Melt Adhesive, Neutral Glass Glue.

* Food Industrial: Soft Candy, Gum, Chocolate.

* Chemical Industrial: Tooth Paste, Soap, Cosmetic Dye.

* Organic Industrial: Butyl Rubber, Organic Silicon, Silicon Rubber, Carbon Fiber, Plastic, Cellulose, Resin

* Energy Industrial: Battery Paste, Aluminium Paste

* Others: Paper Pulp, Print Ink, Architectural Coating, Pigment, Pharmaceutical .

* Food Industrial: Soft Candy, Gum, Chocolate.

* Chemical Industrial: Tooth Paste, Soap, Cosmetic Dye.

* Organic Industrial: Butyl Rubber, Organic Silicon, Silicon Rubber, Carbon Fiber, Plastic, Cellulose, Resin

* Energy Industrial: Battery Paste, Aluminium Paste

* Others: Paper Pulp, Print Ink, Architectural Coating, Pigment, Pharmaceutical .

Specification

Technical Parameters | ||||||||||

Equipment | Double Planetary Mixer | |||||||||

Mixing Volume | 5L | 15L | 30L | 50L | 100L | |||||

Barrel Size (mm) | D280*180 | D280*325 | D400*325 | D480*365 | D550*550 | |||||

Spindle Motor Power (KW) | 1.5 | 2.2 | 3 | 4 | 5.5 | |||||

Spindle Speed (RPM) | 0~60 | 0~60 | 0~84 | 0~62 | 0~70 | |||||

Planetary Speed (RPM) | 0~100 | 0~100 | 0~130 | 0~75 | 0~110 | |||||

Disperser Speed (RPM) | 0~2800 | |||||||||

Vacuum Pressure | -0.098MPa | |||||||||

Lift Range (mm) | 360 | 400 | 430 | 650 | 700 | |||||

Equipment | Double Planetary Mixer with 2 Driver | ||||

Mixing Volume | 300L | 500L | 1000L | ||

Barrel Size (mm) | D850*650 | D960*810 | D1160*1100 | ||

Spindle Motor Power (KW) | 18.5 | 22 | 30~37 | ||

Spindle Speed (RPM) | 0~45 | 0~35 | 0~35 | ||

Planetary Speed (RPM) | 0~62 | 0~60 | 0~45 | ||

Disperser Speed (RPM) | 0~1300 | ||||

Vacuum Pressure | -0.098MPa | ||||

Lift Range (mm) | 900 | 1000 | 1100 | ||

1. Specially used for high viscosity medium which is up to 2,000,000 cPs, max mixing volume 1000L. Once high peripheral velocity increase 5m/s, will reduce mixing time by 20~30 min.

2. Main blade revolves around main axis while 1-2 planetary blade /disperser revolves around it’s own axis, it makes material flow in all directions for better mixing effect.

3. Vacuum style for sealing reaction, Heating / Cooling Jacket for temperature control. Max vacuum is -0.098MPa. Equip good quality bearing for non-loss rotation.

.

.

* Precision assembly, good Concentricity and Planeness.

* Running smoothly, low noise, mixing no dead point.

.

The Planetary Mixer consist of Motor, Lift Device, Top Tank Cover, Main Shaft, Disperser Shaft, etc.

There are many shaft styles available, to achieve multi function of dispersing, stirring, mixing, dissolving, blending, etc.

For different mixing request, there are many styles, like Ex-proof style, Full Stainless Steel style, etc.

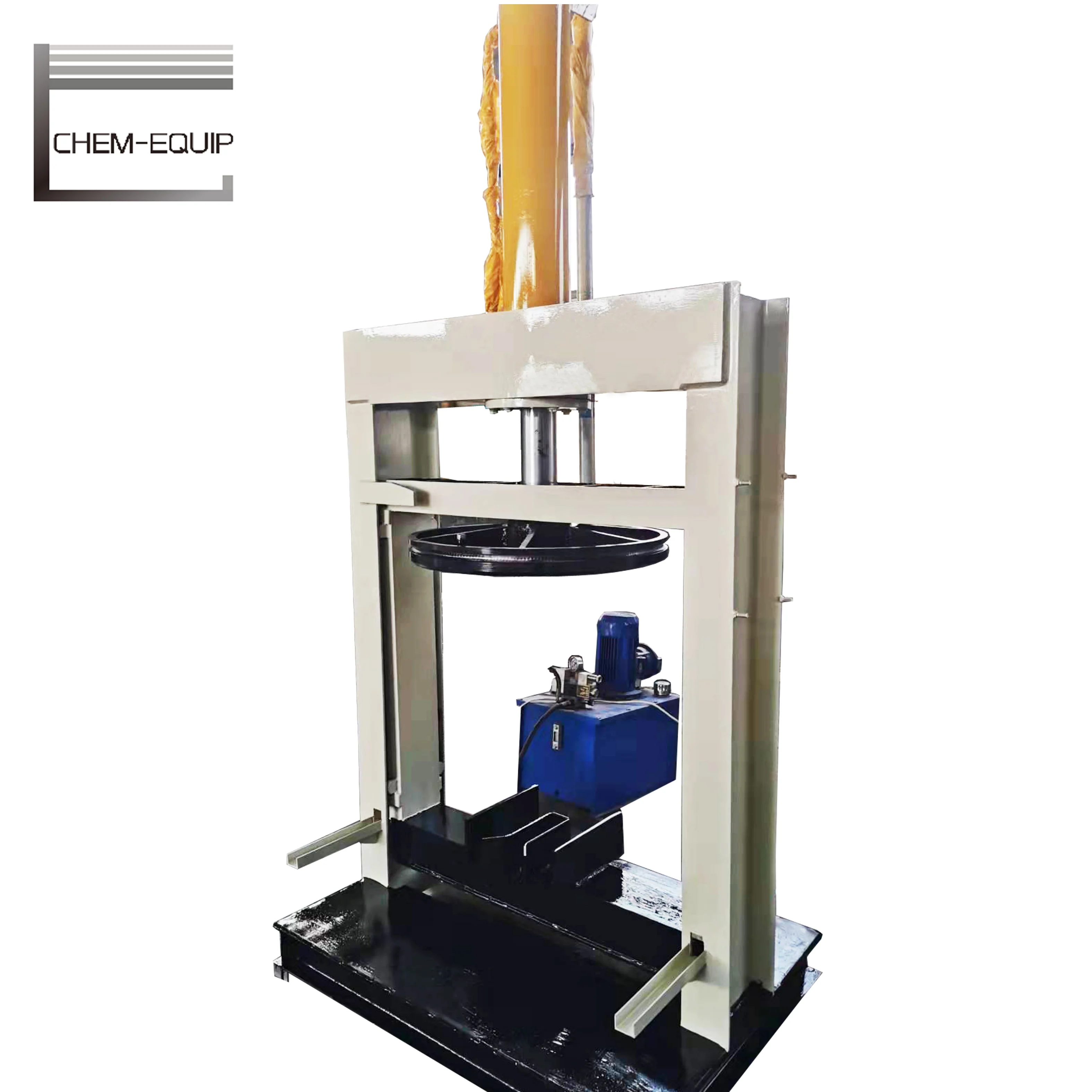

For easy discharging, can equip Hydraulic Pressing Machine to push final products out from above direction. All styles can be made as per request.

Packing & Delivery

Plastic film wrapping against moisture;

Wood Case for spare parts;

Strong fixture for whole set equipment inside container;

All wood used in package is Fumigation free type, no need extra inspection during custom.

Company Profile

With 10 years experience in chemical industry,

Weihai Chem-Equip Machinery Co., Ltd is a professional supplier in various chemical equipment, we help customer design, develop and fabricate suitable production lines, from initial chemical process design, to workshop building and long term maintaince.

We have own factories in Weihai and Laizhou area, product covers Reactor, Pressure Vessel, Mixer, Kneader, Sand Miller, Filter, Dryer etc, almost cover all chemical industry.

With our Chemical Process Designer, ASME AI (Authorized Inspector), American CWI (Certified Welding Inspector), we dedicate in a Turn-Key solution for customers who wants to build up new factory or expand new production lines, in an efficient and safety way.

We have own factories in Weihai and Laizhou area, product covers Reactor, Pressure Vessel, Mixer, Kneader, Sand Miller, Filter, Dryer etc, almost cover all chemical industry.

With our Chemical Process Designer, ASME AI (Authorized Inspector), American CWI (Certified Welding Inspector), we dedicate in a Turn-Key solution for customers who wants to build up new factory or expand new production lines, in an efficient and safety way.

FAQ

Pre-Sale Stage

Provide Chemical Process , Project Drawing and Suitable Equipment Model according to customer's request, for accurate design and quote, please kindly advise below:

Whole time report for manufacture status;

Inspection video for quality checking;

Full set Engineering Documents, include User Manual, General Drawing, Electric Circuit Drawing, All Related Test Report, Approval Certificate.

Life long service for all equipment;

Free spare parts in warranty period;

Discount price for all spare parts after warranty period;

Technical consulting is always for free.

Arrange engineer to assist customer in equipment assembly and installation;

Training workers to use machine properly.

Похожие товары

Новое поступление 2023 роскошные великолепные серьги в европейском и американском стиле Лидер продаж Женские Ювелирные изделия очаровательные кольца на

6,00 $ - 12,00 $

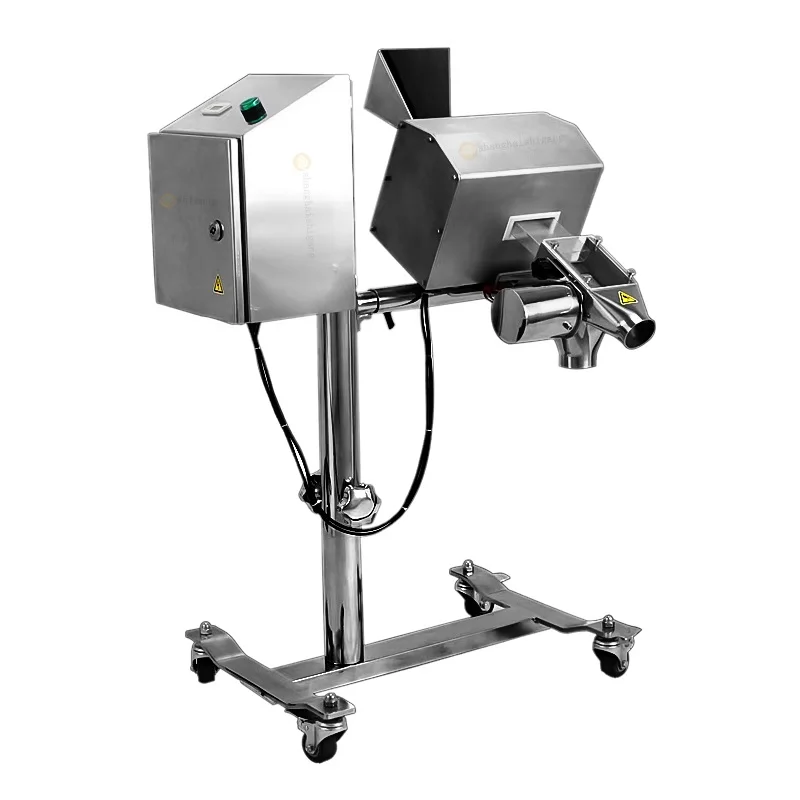

Полностью Автоматическая цифровая Вертикальная капсула свободного падения планшет металлоискатель машина для фармацевтической

3 500,00 $ - 3 900,00 $

SGS сертификаты легко Чистить стекло подарок бутылка

Оптовая продажа титановой фиксированной дорожной рамы с одной

450,00 $ - 720,00 $

Growatt на сетке солнечный инвертор 2 кВт 3 кВт 5 кВт 8 кВт 10 кВт 1-фазный солнечный инвертор с контроллером MPPT

1 099,00 $ - 1 999,00 $

Rhinoceros мини экскаватор 1000 кг машина XN10 с низкой ценой

3 880,00 $ - 4 230,00 $

Многофункциональный высокоскоростной адаптер Mirascreen USB C 3,0 8 в 1 для SD TF HDMI 4K Hub Док-станция для мобильных телефонов ноутбуков Mac тв проекторов

15,50 $ - 18,80 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $