UHT Стерилизатор л машина для пастеризации молока пластинчатый теплообменник

- Категория: >>>

- Поставщик: Shandong Propellent Energy Technology Co. Ltd.

Сохранить в закладки 1600549803146:

Описание и отзывы

Характеристики

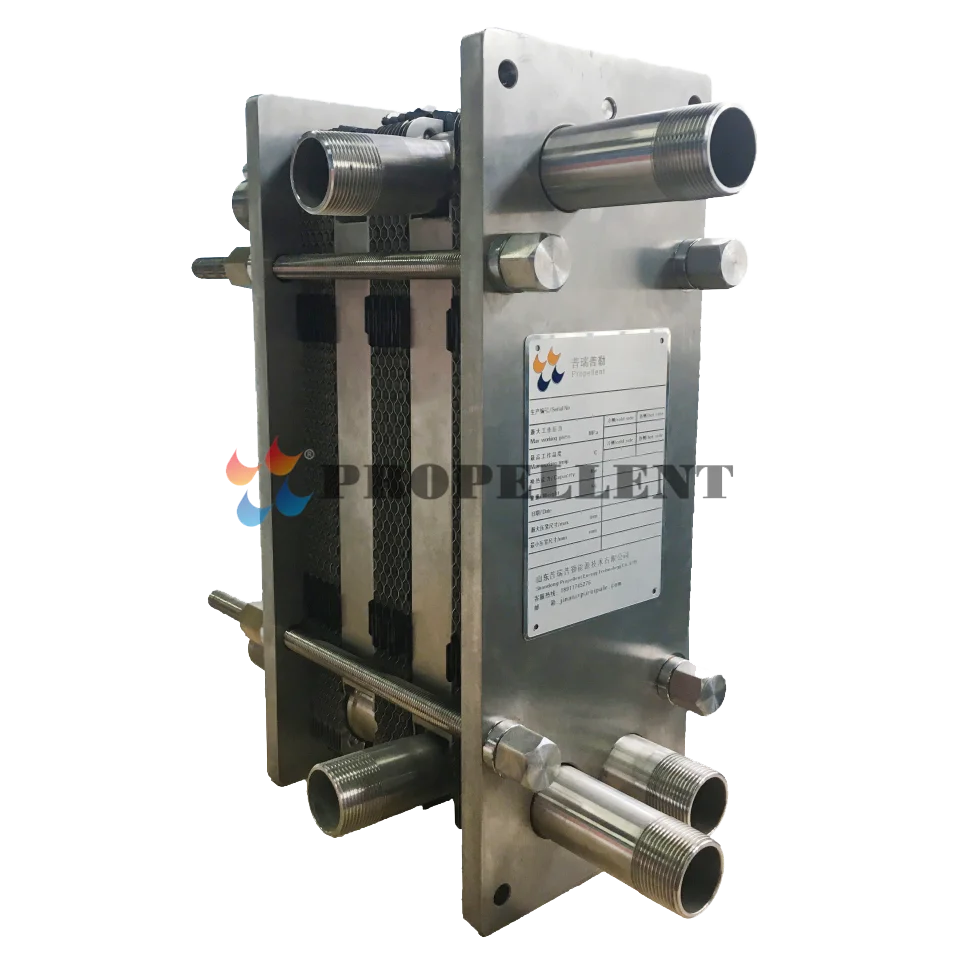

UHT sterilizer 1000L Milk Pasteurization machine plate heat exchanger

Basic information

each plate contains two parts:

Metal plate:It is an important heat transfer element for pressing metal sheet with corrugation, sealing groove and corner hole.

Corrugated not only can strengthen heat transfer, and can increase the sheet and rigid, so as to improve the bearing capacity of the plate heat exchanger, and because turbulence prompted the liquid state, so it can reduce the formation of sediment or dirt, play a role in "self-cleaning".

Sealing gasket: installed in the slots along the perimeter of the plate of the gasket and seal plate between the peripheral, prevent fluid leak outward, and according to the requirements of design, the sealing part of the Angle of hole, the cold and hot liquids according to their respective port flow.

Sealing principle:

The corrugated plate is pasted with sealing gasket, which is designed to double seal structure and has signal hole.When the medium leaks from the first seal, it can leak out from the signal hole, and the problem can be detected and solved as soon as possible, without causing the mixing of the two media.Sealing gasket according to different media and operating temperature to choose different types of rubber.

1.Advanced plate design to improve heat transfer efficiency.

2.Uniform distribution of fluid, accurate positioning.

3.Common types of plate heat exchanger plates at home and abroad.

4.Reasonable shunt area, enhance corrosion resistance, improve the utilization rate of heat exchange area.

5.The reverse flow of the two fluids greatly improves the heat exchange efficiency.

6.Parallel piping of the same fluid inlet and outlet simplifies engineering installation.

7.Single plate, simplified maintenance.

Plate Material

| Available Medium | |

| AISI304, AISI316L | Pure Water, Fresh Water, Mineral Water |

| Titanium | Sea Water, Mineral Oil, Vegetable Water |

| 254SMO | Dulute Sulphuric Acid etc. |

| Ni | Caustic Soda with high temperature and concentraction |

| Hastelloy | Concentration Sulphuric Acid etc. |

Application areas/occasions:

Propellent, is the Booster and leader of effective heat exchange technology in all industries.

Propellent can be able to offer a full range of heat exchange design calculation in full working condition. We have accumulated rich experience in heating, cooling and waste heat recovery for complex process mediums. Propellent never views separately in the selection of heat exchange equipment applications, but put it in the whole process production line, Therefore, we find the best balance to consider the whole initial investment in equipment and long-term operating costs. We optimize manufacturing processes of our clients and reduce the use of fresh energy to provide our customers maximum value when we find reasonable main points in high heat transfer efficiency and pressure loss.

Propellent enterprises, has always been insisting this operation principle: Opening-up and cooperation, mutual improvement with cooperative partner and growing together with employees from the date of birth, to promote the progress of industry and business.

The leading heat transfer technology of Propellent, always from in the forefront of the heat exchange field all over the world, it is our belief that common sense is not constrained by experience, having the courage to take risks and depending on the talent as the most fundamental wealth.

1. We always think from the perspective of customers, solve problems and bring higher value to customers

2. More than 15 years of professional experience and expert team

3. Professional production r&d team to improve heat exchange efficiency and reduce operating costs

4. The technical scheme of guaranteed commitment

5. Whole process service from pre-sale to after-sale

6. Help customers reduce risks and save costs to maximize customer benefits

If you have any need, please contact us.

Похожие товары

Высокоэффективная машина для депиляции свиной кожи-машина для удаления волоса из коровьей кожи на продажу

CE ISO стоматологический HEMINGWAY LUCAS костной каретка, хирургический периодонтальный высококачественный Лукас из нержавеющей стали Hu-Friedy DE хирургический каретка

5 Вт питания модуль, 12 В до 24 В преобразователь постоянного тока

Красный королевский Краб/синий краб/русский Королевский краб

600 Вт холодная машина для фейерверка pyro spark фонтана свадебной

MS 660 бензопила цена для

51 мм/54 мм 57/57.5/58 Чой деревянной ручкой для трамбовки кофе вместимость ящика кофейного порошка плоское основание кафе бариста Инструменты машина эспрессо

Новые поступления

Новинки товаров от производителей по оптовым ценам