1308 1313 165 мм 4 Лопасти pdc резаки для горных работ сверла

- Категория: >>>

- Поставщик: Hunan Diyfia Group Company

Сохранить в закладки 1600551761310:

Описание и отзывы

Характеристики

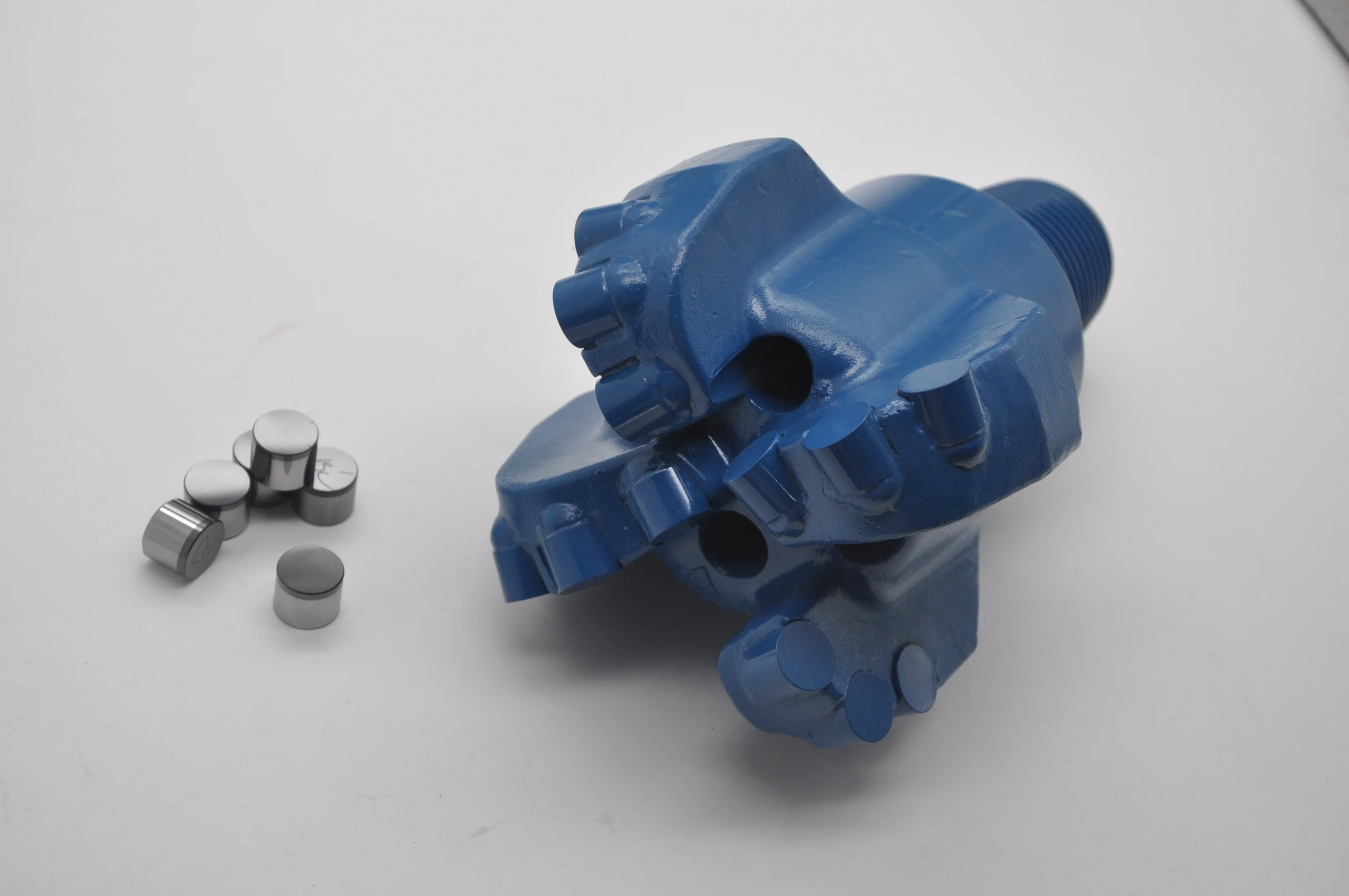

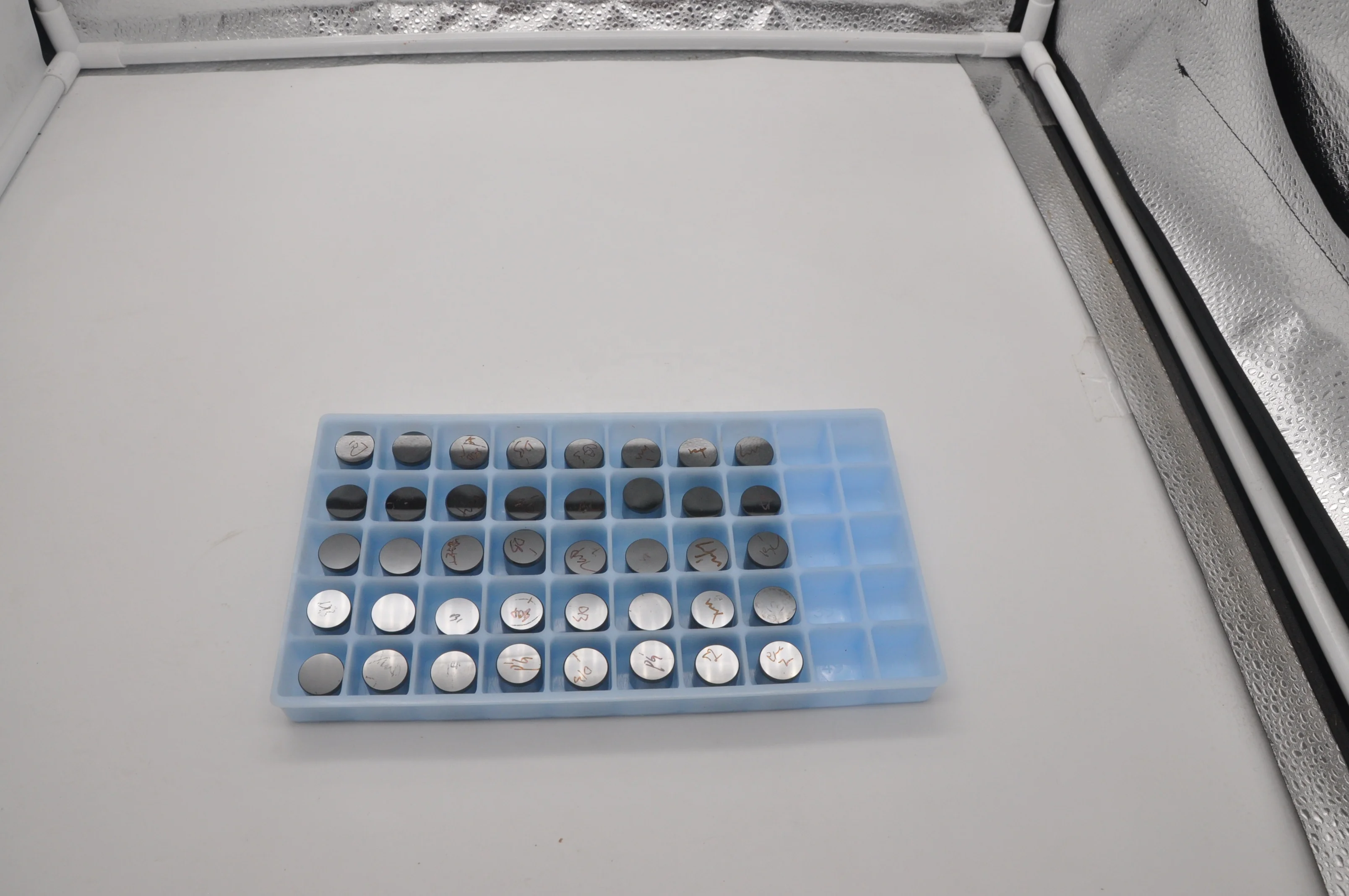

1308 1313 165mm 4 blade pdc cutters for mining drilling bits

Our PDC diamond core bits are the most commonly useful bits in the mineral exploration industry, as they have the widest range of application. The carefully selected grades of high quality synthetic diamond are distributed in the depth of impregnated bit's matrix series. The matrix layer of the "DIYFIA" contains a uniform distribution of these crystal that are embedded in a powdered metal bond.

1. PDC bit is mainly used for drilling soft and medium formation, it work under low drilling pressure,midium-low speed,big drainage. PDC drill bits are mainly used for drilling soft and medium - hard formation,it’s the preferred choice in general non-coring drilling in soft and middle hard formation, such as mud stone, limestone, shale, sandstone and granite etc, very high cost -effective.But easy to wear when drilling abasive formations.

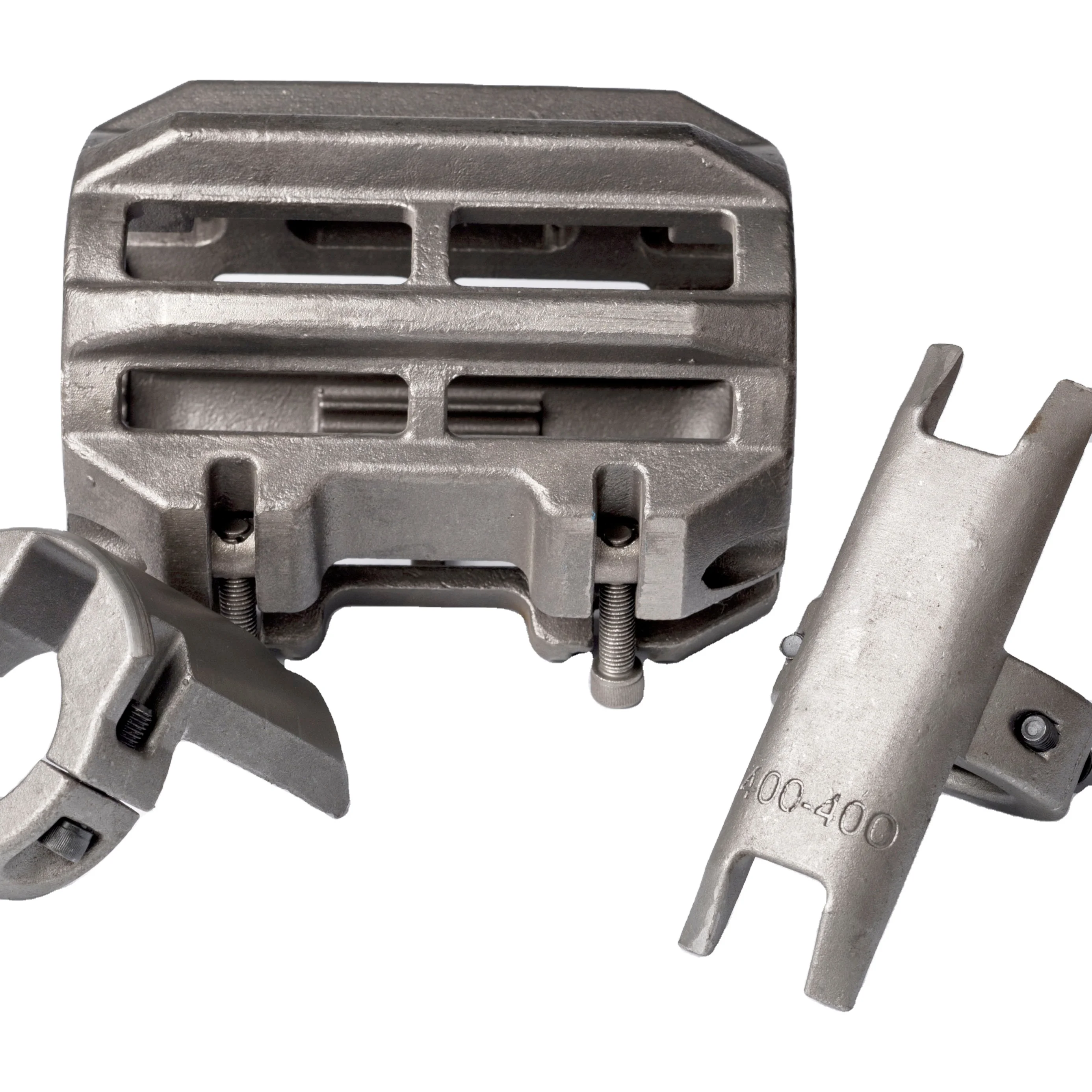

2. We can supply all kinds of PDC Coring and non-coring bits, PDC sintering matrix bits and PDC anchoring bits. PDC bit can be widely used in the fields of geological exploration, coal mining, water conservancy and hydropower, construction of road and railway.

Size details as below:

PDC Drill Bit Specifications | |||

Item | Size | Item Name | Size |

Non-coring Drill Bit | 42 | Coring Drill Bit | 75 |

Non-coring Drill Bit | 46 | Coring Drill Bit | 78 |

Non-coring Drill Bit | 46 | Coring Drill Bit | 94 |

Non-coring Drill Bit | 56 | Coring Drill Bit | 94 |

Non-coring Drill Bit | 60 | Coring Drill Bit | 98 |

Non-coring Drill Bit | 65 | Coring Drill Bit | 100 |

Non-coring Drill Bit | 75 | Coring Drill Bit | 113 |

Non-coring Drill Bit | 94 | Coring Drill Bit | 133 |

Non-coring Drill Bit | 94 | Coring Drill Bit | 153 |

Non-coring Drill Bit | 98 | Multiple-cones Drill Bit | 94 |

Non-coring Drill Bit | 100 | Multiple-cones Drill Bit | 98 |

Non-coring Drill Bit | 113 | Multiple-cones Drill Bit | 113 |

Non-coring Drill Bit | 133 | Multiple-cones Drill Bit | 133 |

Non-coring Drill Bit | 153 | Scraper Drill Bit | 113 |

Coring Drill Bit | 65 | Scraper Drill Bit | 133 |

Our Company pas atention to produce quality and abides to credit, and also does the best to provide the quality produdcts and excellent service to customer. To build good after-sale service system, we draw up the Quality Guarantee according to the industrial standards combining field experience.

| Diamond Drill Bits | 1. Size, and / or technical parameters(matrix etc.) are different from the requirements of clients' purchase order.

| Replace |

2. Thread can not fit clients' barrel.

| Repair or replace | |

3. Break down a piece from matrix, and the volume of the piece exceed 2mm*2mm*2mm, and such break is not caused by drilling.

| Replace | |

4. Matrix falling not caused by drilling.

| Replace or return | |

5. Groove on matrix caused by manufacturer.

| Replace or return | |

6. Drilling speed is obvious slower than congener products caused by manufacturer.

| Raplace,and each item quantity does not exceed 3pieces. | |

7. Bit life is obvious short caused by manufacturer.

| ||

8. Breaking down of matrix, falling matrix, groove and short bit life caused by operating reasons-drill rod sticking, premature failure of the bit crown and hole-bottom not to be cleaned.

| Be excluded from Qulity Guarantee | |

9. Short bit life or no penetration caused by drilling machine, drilling techniques or parameters.

| ||

10. Properly worn and the matrix is finished.

| ||

11. Thread damaged or distorted due to improper operation.

| ||

12. Steel body cracked in drill.

| Replace or return | |

| Reaming shell | 1. Thread is not correct.

| Replace or return. |

2. Steel body creacked in drill.

| ||

3. PCD Strips falling.

|

Picture of PDC Core drill bits

Pictures of NON-Coring PDC Bits

Other diamond core drill bits picture:

FAQ:

===================================

The information you may like to know before order:

1. Methods of Payment: T/T (Telegraphic Transfer) or Western Union or L/C at sight

2. Handling time for an order Within 30 days supplied from stock

3. Shipping way Normally it is by sea ,by express .

4.Quality Control We have our own experienced QC. There will be strict inspection and testing for every order before shipping out.

5. After-Sale Services:

a. Our sales team will reply for your question within 24 hours (Holidays Excluded)

b. Technical Support will be available in any time

c. Free replacement will provide once the failure confirmed caused by our product quality.

Похожие товары

Оборудование для заливки масла из углеродистой стали ESP Скважинные инструменты протектор кабеля в середине соединения

Масляный насос для забойного литья углеродистая сталь поперечная муфта кабельная защита

7/11/12 Коническое сверло и инструменты для сверления верхнего молотка каменной кнопки горного дела

Буровое долото для бурения 12 1/4 16 18 22 28 дюймов б/у

Высокая производительность 32 мм 34 36 38 мм-7/11 / 12 градусов коническая Кнопка сверла

Полностью Отлитый масляный насос из нержавеющей стали поперечная муфта кабельный протектор предназначен для защиты кабелей

Профессиональное литье из углеродистой стали масляного оборудования MLE протектор защищающий кабель и линии управления

Новые поступления

Новинки товаров от производителей по оптовым ценам