Линия гранулирования ПЭТ волокна экструдер для полиэфирной

- Категория: Plastic Granulators >>>

- Поставщик: Jiangsu Mooge Machine Co. Ltd.

Сохранить в закладки 1600557558005:

Описание и отзывы

Характеристики

Products Description

PET waste Fiber pelletizing line

This line is used to waste fiber pelletizing machine ,such as polyester ,yarn,polyester staple,polyester filament ,yarn and so on. The line main machine include plastic crusher machine (use to crush waste fiber),material transit tank(after crushing ,we using blower to send it into tank),compactor feeding cutter machine(we have 3 set rotor blade on the bottom and fixed blade on the wall).

Single stage extruder machine(The screw made by 38CrMnAl,,nitriding treatment which can used for long lifetime),Roots vacuum pump,Non-stop hydraulic screen changer(big area filter ),4m or 6m water cooling tank(made by 304 stainless steel ),dryer ,pelletizer cutting machine,silo (volume 1 CBM and made by 304 stainless steel ) and so on .

We also can customized it to you according to you requirement.

We also can customized it to you according to you requirement.

Model | Screw Dia. | Screw L/D | Main Motor Power | Capacity Kg/hr |

PSF-SJ100 | 100mm | 35-38:1 | 55KW | 150-200Kg/hr |

PSF-SJ100 | 100mm | 35-38:1 | 75KW | 200-300Kg/hr |

PSF-SJ130 | 130mm | 35-38:1 | 90KW | 300-400kg/hr |

PSF-SJ160 | 160mm | 35-38:1 | 110KW | 400-500Kg/hr |

PSF-SJ180 | 180mm | 35-38:1 | 160KW | 500-600Kg/hr |

PSF-SJ200 | 200mm | 35-38:1 | 200KW | 600-800Kg/hr |

Features

Fiber pre-crushing system

Single stage Model

Compacting force feeding system

Adopt Hard teeth ZLYJ-type gearbox branded

With strong Roots vacuum system

Big area screen filter

Advanced pelletizier cutter

Single stage Model

Compacting force feeding system

Adopt Hard teeth ZLYJ-type gearbox branded

With strong Roots vacuum system

Big area screen filter

Advanced pelletizier cutter

Product Pictures

Compactor

With multi blades crushing and compulsively compress the flakes into extruder, ensure high efficient and stable production.

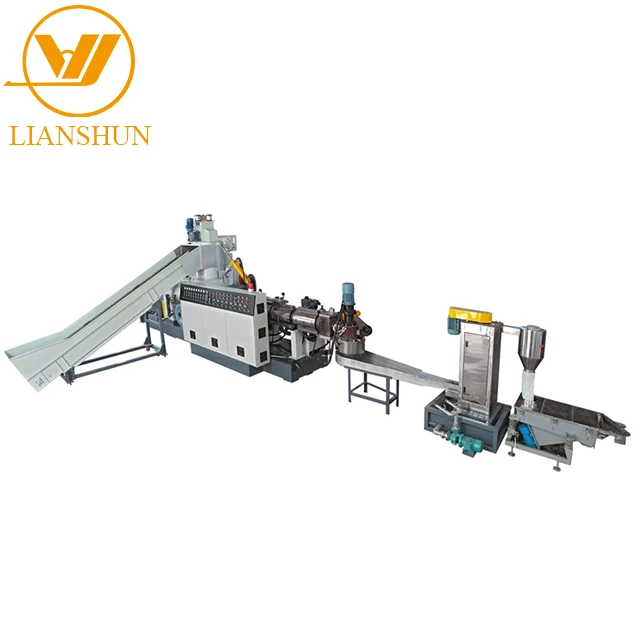

Belt Conveyor

Feeding PP PE film bag or flakes into compactor. If too much scrap irons, metal detector may be needed.

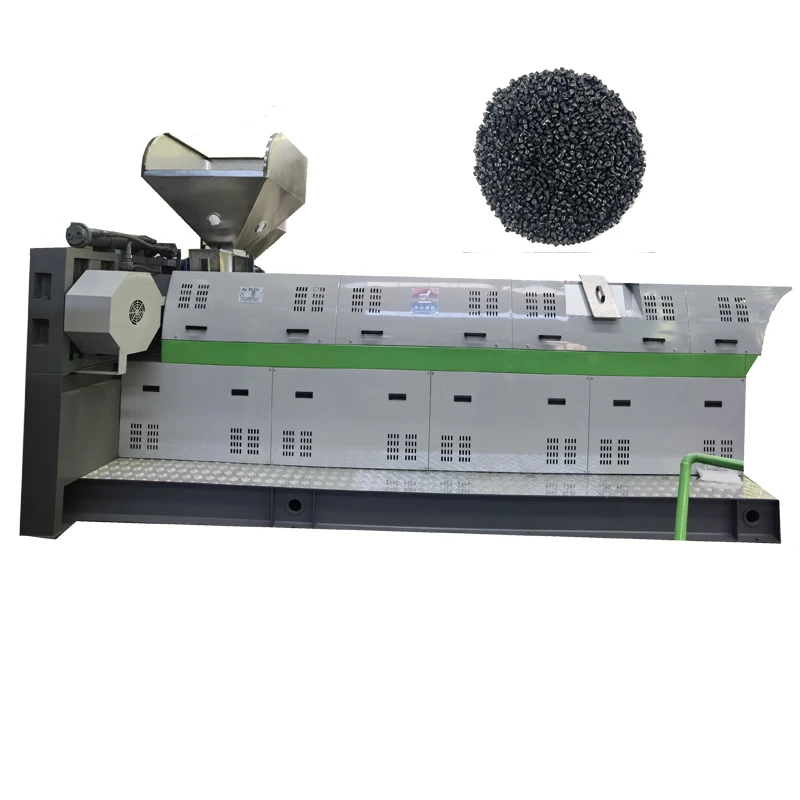

Single Screw Extruder

Plasticizing material with high temperature and exhausting hot gas.

Hydraulic Screen Exchanger

Filter material impurity to make production more stable.

Die Model

Materials come out in long strap

Materials come out in long strap

Water Tank

Cooling the pellets with cold water.

Cooling the pellets with cold water.

Air Drying System

Drying the strap

Drying the strap

Pelletizer Cutter

Cutting pellets with high speed rotation.

Cutting pellets with high speed rotation.

Vibration Screen

Pick out bad pellets and keep good pellets

Pick out bad pellets and keep good pellets

Air blower and Silo

collecting pellets

collecting pellets

Packing and Delivery

• For the loose cargo we will packing by wooden box.

• For the full container loading we are packing the machine by film and some on pallet accordingly.

• We can also ship the goods by air or by sea as buyer request.

• We will send pictures of cargo loading to our client to check and keep recording.

• We can send cargo to client's warehouse to loading.

• For the full container loading we are packing the machine by film and some on pallet accordingly.

• We can also ship the goods by air or by sea as buyer request.

• We will send pictures of cargo loading to our client to check and keep recording.

• We can send cargo to client's warehouse to loading.

Our Service

• Pre-sale: we give our client the detailed technician offer, sign the sales contract etc.

• In-sales: we supply the details layout, installation instruction, and technician support for the clients.

• After sales: we arrange engineer to install the machine and train the workers for our client.

• We have 24 hours service line to solve the after sales problem.

• We have free spare parts with the machine.

• We supply long term spare parts for every customer.

• We always update the new technology to every customer.

• In-sales: we supply the details layout, installation instruction, and technician support for the clients.

• After sales: we arrange engineer to install the machine and train the workers for our client.

• We have 24 hours service line to solve the after sales problem.

• We have free spare parts with the machine.

• We supply long term spare parts for every customer.

• We always update the new technology to every customer.

Our company

Похожие товары

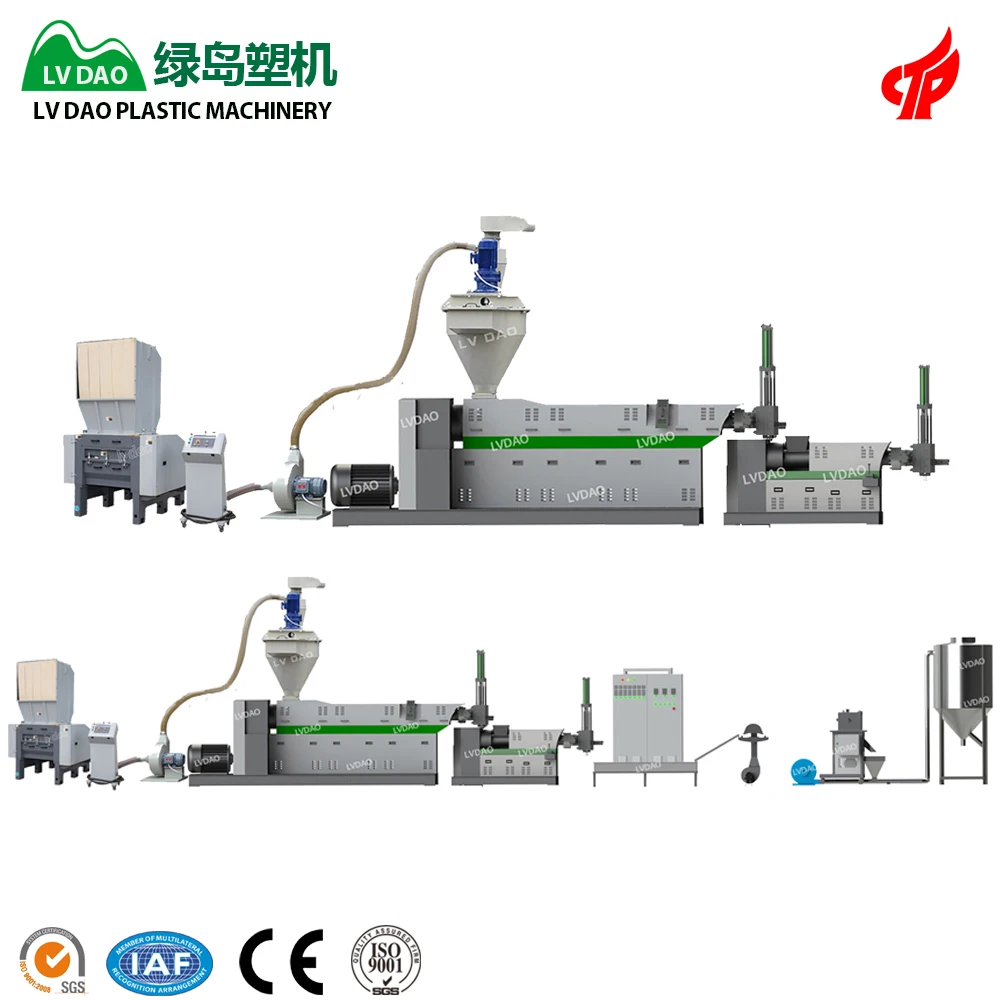

Новейшая линия по производству гранулирования ПП ПЭ пленки/сырье из отходов пластика мешки оборудование

15 800,00 $ - 16 000,00 $

Высококачественная машина для гранулирования полиэтиленовой пленки линия

Гранулятор PP PE PET HDPE LDPE LLDPE гранулятор для гранулирования машина переработки с сертификатом

35 000,00 $ - 45 000,00 $

Производитель оборудования Lvdao гранулятор полипропиленовых и полиэтиленовых отходов линейный

10 000,00 $ - 37 500,00 $

Низкая цена новая технология машина для переработки пластика Pp Pe и

15 850,00 $

Полипропилен, ПЭТ, мешок для мусора, ПЭТ, гранулятор для переработки пленки ПЭТ, машина для гранулирования отходов, пластиковый гранулятор

18 800,00 $

Гранулятор LSSJ100/33 280-350 кг/ч для переработки отходов пластиковой ПП ПЭ

38 800,00 $ - 39 000,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $