Полипропиленовая машина для спиннинга fdy MFP/многонитевая пряжа pp CF

- Категория: Spinning Machines >>>

- Поставщик: Taian Jiamei Machinery Technology Co. Ltd.

Сохранить в закладки 1600568155063:

Описание и отзывы

Характеристики

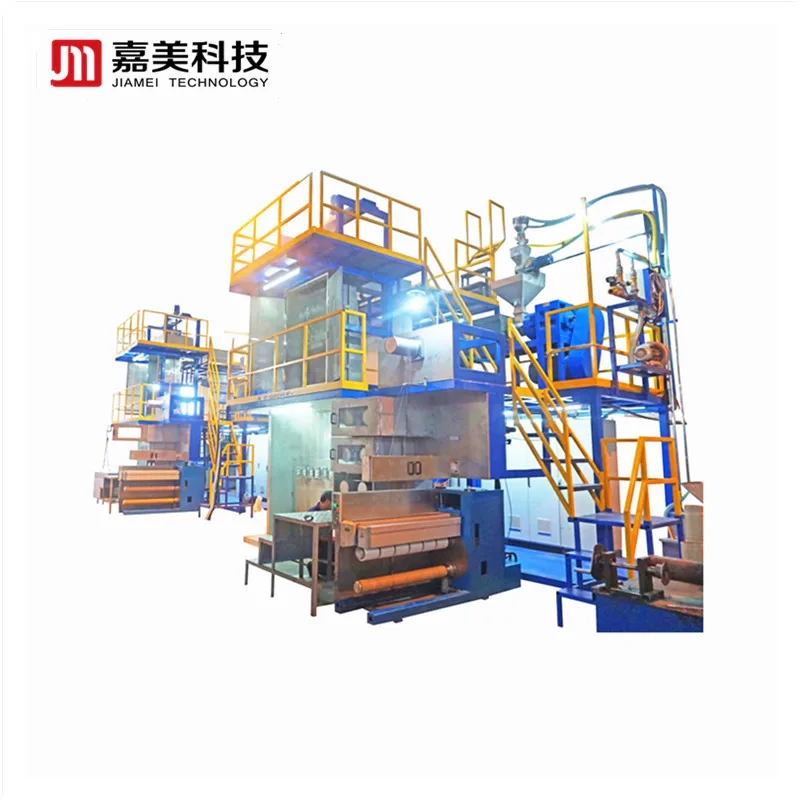

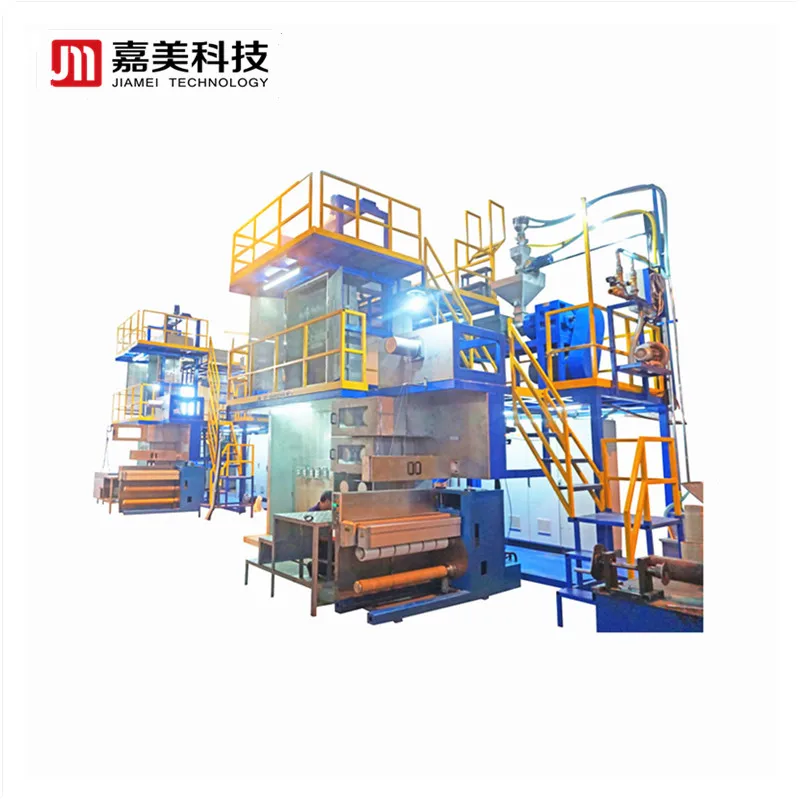

polypropylene fdy MFP filament spinning machine/ pp CF multifilament yarn plant

pp fdy plant

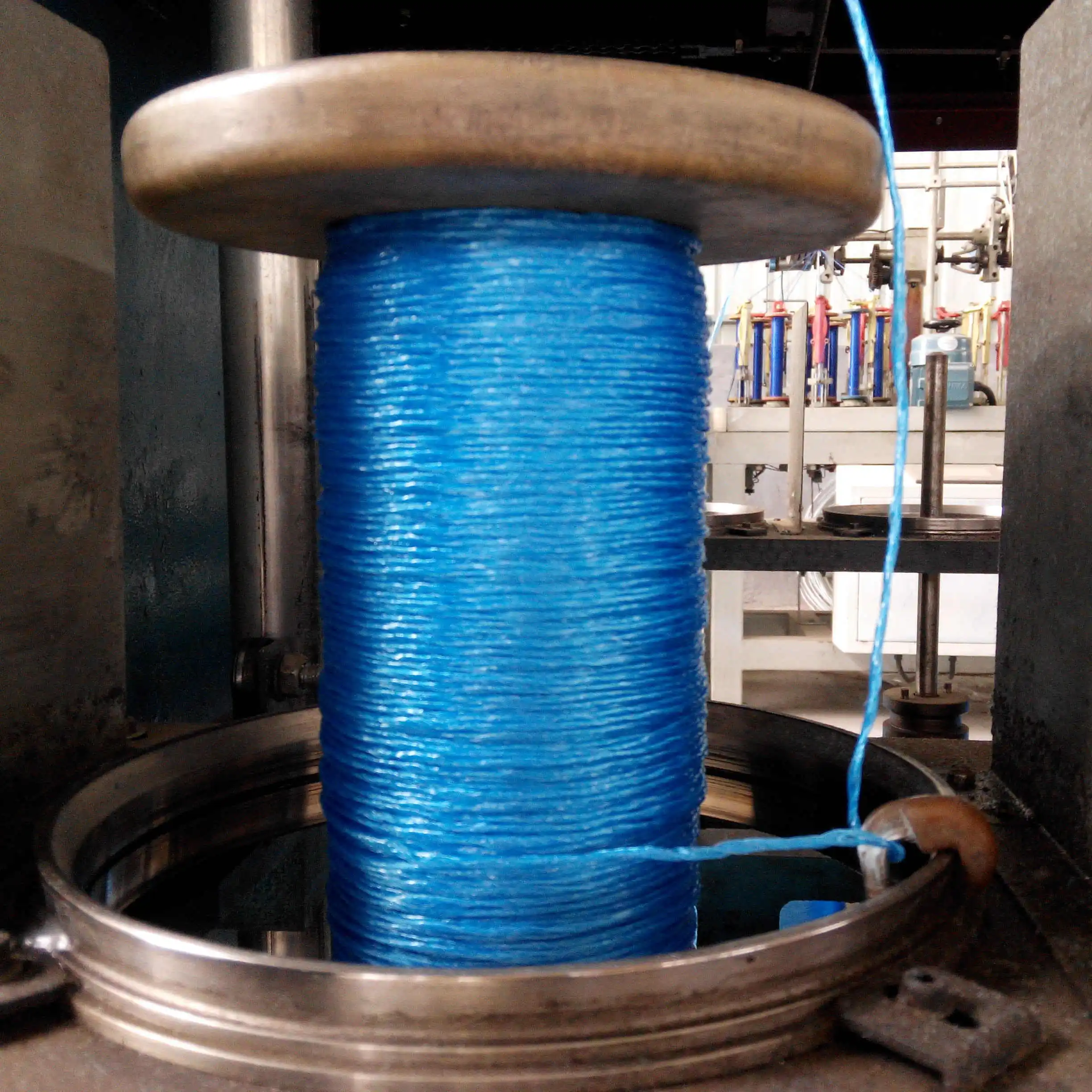

pp yarn spinning machine is for extrusion drawing winding MFP filament, automatic bobbin change winder , PLC with touch screen

l Low Power consumption : 1kg yarn /1-1.2 kwh power

l Fast assemble and training : 12-15 days

l High tenacity : >=6.5g/d raw white yarn, >=5.5g/d color yarn

l Easy operate : PLC control + touch screen

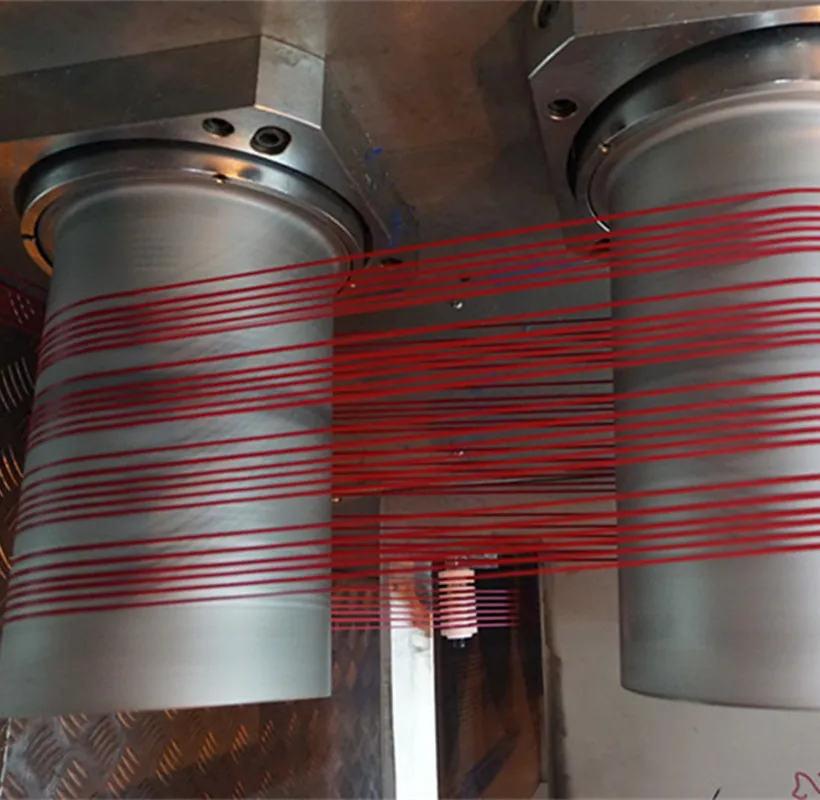

l intermingle: 15-30

pp yarn spinning machine

pp multifilament spinning line, model

Item | JM261 | JM241 | JM811 | JM161 | JM141 |

Pos | 2 | 2 | 1 | 1 | 1 |

Fibre denier | 500-1500D( SINGLE YARN) | ||||

Spinneret/pos | 6 | 4 | 8 | 6 | 4 |

Winder speed | 2000-2400m/min | ||||

Capacity (900d) | 3.5toms | 2.3tons | 2.3tons | 1.7tons | 1.2tons |

Screw dia | 120mm | 105mm | 90mm | 90mm | 70mm |

Power | 280kw | 130kw | 120kw | 150kw | 120kw |

Machine size | 5.5*5*6.5m | ||||

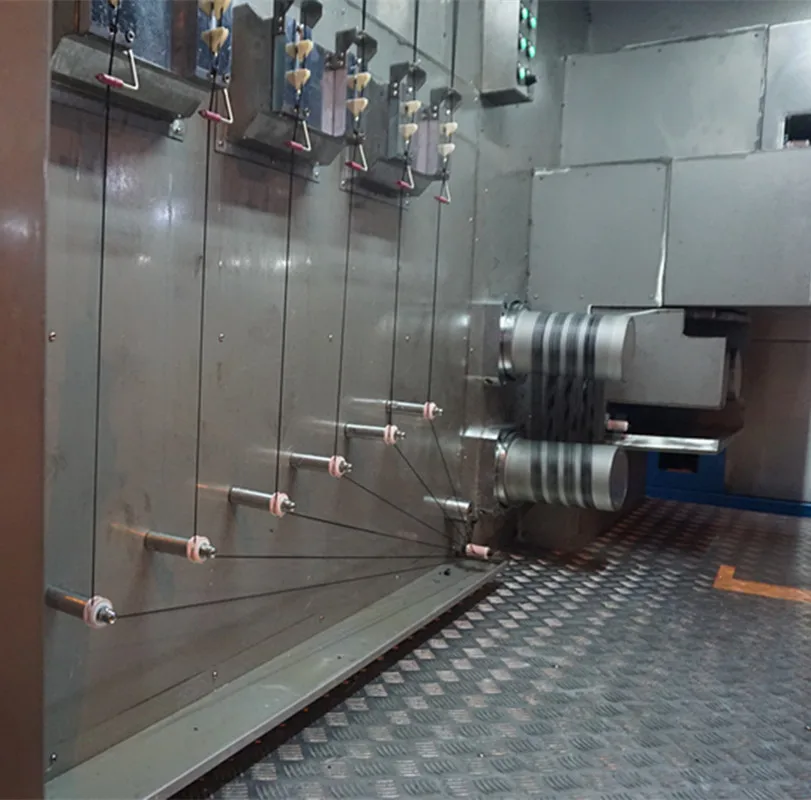

MFP ( MULTIFILAMENT POLYPROPYLNE ) PHOTO

1. webbing and belt making

2. sewing thread

3. rope production

4. concrete and cement fibre

5. filter cloth

6. sofa, beach bed, beach chair, Beach hammock

7. zipper/ fastener yarn

Specification of fdy yarn machine

1. dscription of pp fdy machine

fdy yarn machine

applied on this line includes the direct stretching and intermingling of the yarn in one step, which has the following advantages.

1.) Best relation between PLC control and output.

2.) Low production costs because of one-step process, reducing space, labor and energy-consumption.

3.) online spin-finish application

4.) Elimination of twisting due to intermingling process.

5.) The short polymer residence time ensures high flexibility and versatility for the production with high quality colored yarn.

2) machine installation (fdy yarn machine)

Come engineer set up machine ,take 10 days for assemble and trainning .

The customer should prepare 3-5 workers for learn and operate the machine .

With online device ,our team is 24hr at your service .

3) company profile ( yarn spinning machine )

fdy yarn machine

1. Machine Manufacturing years: over 30 years

2. Workshop area: 10000square meters

3. Qty of workers: 80-100

4. We have yarn production with own machine over 15 years

1*40HC+1*20GP

SPARES

We also offer client the spares like

spinneret( die), intermingle( for airjet), metering pump, hot godet, automatic pp fdy winder, plastic traverse, ceramic hook( yarn guide hook), heating ring etc

fdy yarn machine

pls contact me if any enquiry

Похожие товары

Качественная ведущая машина для скручивания Полипропиленовой пряжи/машина пряжи в

Оборудование для воздушной текстуры машина PP TASLAN Тип

Сверхмощный ткацкий станок новой модели с водяной

Полипропиленовая многонитевая пряжа для спиннинга/fdy pp машина производства

Ткацкие машины/HW-6012 серия 360 см ткацкие станки

Машина для кардинга Tongda MK8 с инверторным управляемым

FDY pp полипропиленовая многонитевая машина для спиннинга/спиннинговые

Новые поступления

Новинки товаров от производителей по оптовым ценам