Сервопривод листогибочный пресс с ЧПУ электрическая машина для гибки металла 40 тонн/1300 мм автоматическая система машины 6 оси

- Категория: >>>

- Поставщик: Dongguan Eko Cnc Technology Co. Ltd.

Сохранить в закладки 1600568683333:

Описание и отзывы

Характеристики

Product Overview

EKO ES4013 with 6 axis press brake

The machine is a 6-axis (D1, D2, Y1, Y2, Z and L) full-servo press brake, dispense with hydraulic oil, free from the influence of

oil temperature variation on the work piece, and the machine tool is more precise, energy-saving and efficient than the oil press.The machine is a 6-axis (D1, D2, Y1, Y2, Z and L) full-servo press brake, dispense with hydraulic oil, free from the influence of

oil temperature variation on the work piece, and the machine tool is more precise, energy-saving and efficient than the oil press.

oil temperature variation on the work piece, and the machine tool is more precise, energy-saving and efficient than the oil press.The machine is a 6-axis (D1, D2, Y1, Y2, Z and L) full-servo press brake, dispense with hydraulic oil, free from the influence of

oil temperature variation on the work piece, and the machine tool is more precise, energy-saving and efficient than the oil press.

PRODUCT CONFIGURATION

Optional controller

Delem DA53T

Delem DA69T

Delem DA66T

STEP Controller

EKO NCmax controller

Optional configuration

WILA new standard and clamping system

DSP Laser protection

Kyokko clamps

Details Images

DSP Italy laser protection

The DSP laser guarding system ensures safe operation. Optical protection remains active until the tool opening is reduced to 2mm, thereby preventing fingers and hands from entering the point of operation.The DSP laser guarding system ensures safe operation. Optical protection remains active until the tool opening is reduced to 2mm, thereby preventing fingers and hands from entering the point of operation.

Kyokko quick clamping system

The Japanese style quick clamping system ensures simple, fast and safe front load tool changing, elimi- nating the time-consuming

nature of the traditional tool change method.

nature of the traditional tool change method.

EKO ES4013 press brake with 6 axis

ES4013 with 6 axis, D1-D2-Y1-Y2-L-Z. It can meet your mult -type of bending angle.

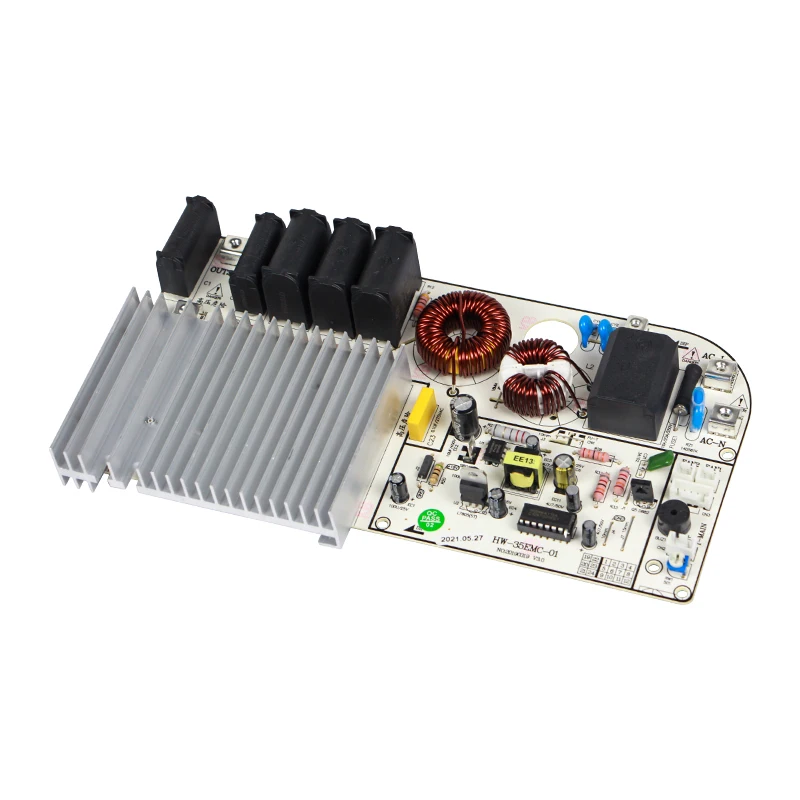

Powerful SANYO DENKI servos

The left and right ram are controlled by heavy duty servo drives and motors from Japanese giant Sanyo Denki. Unmatched in durability, these large format servo motors allow accurate bending with up to 125 tonnes of force. The left and right ram are controlled by heavy duty servo drives and motors from Japanese giant Sanyo Denki. Unmatched in

durability, these large format servo motors allow accurate bending with up to 125 tonnes of force.

durability, these large format servo motors allow accurate bending with up to 125 tonnes of force.

MITSUBISHI servo drives & motor

The back gauge is driven by premium Japanese servo motors from Mitsubishi Electric. These high speed servos ensure rapid and precise movement of the axis.

Exhibition

Company Profile

EKO CNC Technology Co.,Ltd. is a high-tech and environment-friendly sheet metal CNC press brake manufacturer. The product technology comes from the "blood" of the international industry.

EKO has four series of high-quality press brake: "ES", "EHII", "ET" and "ESS". There are strong technological strength, innovative equipment development concepts, the professional development team, self-core technology and numbers of new technological innovation patents. The market covers all over the world.

EKO pays attention to the construction of enterprise culture, builds enterprise culture brand, and integrates enterprise culture into products. EKO adhere to the principle of "continuous improvement and continuous innovation" to build a self-contained system. Adheres to the quality policy of "customer satisfaction is our pursuit, quality assurance is our commitment", which is guided by customer needs and based on high-quality products to ensure product quality. Continue to provide customers with high-precision, high-efficiency, safety, stable, energy-saving, environmentally-friendly sheet metal processing machine.EKO CNC Technology Co.,Ltd. is a high-tech and environment-friendly sheet metal CNC press brake manufacturer. The product technology comes from the "blood" of the international industry.

EKO has four series of high-quality press brake: "ES", "EHII", "ET" and "ESS". There are strong technological strength, innovative equipment development concepts, the professional development team, self-core technology and numbers of new technological innovation patents. The market covers all over the world.

EKO pays attention to the construction of enterprise culture, builds enterprise culture brand, and integrates enterprise culture into products. EKO adhere to the principle of "continuous improvement and continuous innovation" to build a self-contained system.

Adheres to the quality policy of "customer satisfaction is our pursuit, quality assurance is our commitment", which is guided by customer needs and based on high-quality products to ensure product quality. Continue to provide customers with high-precision, high-efficiency, safety, stable, energy-saving, environmentally-friendly sheet metal processing machine.

EKO has four series of high-quality press brake: "ES", "EHII", "ET" and "ESS". There are strong technological strength, innovative equipment development concepts, the professional development team, self-core technology and numbers of new technological innovation patents. The market covers all over the world.

EKO pays attention to the construction of enterprise culture, builds enterprise culture brand, and integrates enterprise culture into products. EKO adhere to the principle of "continuous improvement and continuous innovation" to build a self-contained system. Adheres to the quality policy of "customer satisfaction is our pursuit, quality assurance is our commitment", which is guided by customer needs and based on high-quality products to ensure product quality. Continue to provide customers with high-precision, high-efficiency, safety, stable, energy-saving, environmentally-friendly sheet metal processing machine.EKO CNC Technology Co.,Ltd. is a high-tech and environment-friendly sheet metal CNC press brake manufacturer. The product technology comes from the "blood" of the international industry.

EKO has four series of high-quality press brake: "ES", "EHII", "ET" and "ESS". There are strong technological strength, innovative equipment development concepts, the professional development team, self-core technology and numbers of new technological innovation patents. The market covers all over the world.

EKO pays attention to the construction of enterprise culture, builds enterprise culture brand, and integrates enterprise culture into products. EKO adhere to the principle of "continuous improvement and continuous innovation" to build a self-contained system.

Adheres to the quality policy of "customer satisfaction is our pursuit, quality assurance is our commitment", which is guided by customer needs and based on high-quality products to ensure product quality. Continue to provide customers with high-precision, high-efficiency, safety, stable, energy-saving, environmentally-friendly sheet metal processing machine.

Packaging & Delivery

FAQ

1.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis /Conformance; Insurance; Origin, and other export documents where required.

2.What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

The lead times become effective when

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

6.How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

2.What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

The lead times become effective when

(1) we have received your deposit,

(2) we have your final approval for your products. If

our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to

accommodate your needs. In most cases we are able to do so.

3.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.

4.What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the

culture of our company to address and resolve all customer issues to everyone’s satisfaction.

5.Do you guarantee safe and secure delivery of products?

our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to

accommodate your needs. In most cases we are able to do so.

3.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.

4.What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the

culture of our company to address and resolve all customer issues to everyone’s satisfaction.

5.Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

6.How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.

Похожие товары

Модуль электронных компонентов микросхем BOM микроконтроллер UHE-5/6000-D48THL2-C интегральная схема

0,80 $ - 1,50 $

Копилка для денег из акации ручной работы-копилка для монет-подарки для детей, девочек, мальчиков и взрослых

4,59 $ - 5,39 $

Хорошая цена, дизельный топливный насос 0460424209 VE4/12F1350R866-2 3357117 3964815 для Cummins 4BTAA-140 л.с.

Горный велосипед масло весенний Задний амортизатор 190/210/240 мм с мягким хвостом кадр задние противотуманные фонари желчь RCP2S 3 поражения электрическим током для продажи

85,00 $ - 100,00 $

Заводская цена 1000 мл чернила для печати краски Dtf универсальные CMYK цветные пигментные чернила для принтеров DTF

Эпизин Витамин С Сыворотка для лица темные круги ферма болгарское масло

1,50 $ - 1,98 $

JSP, чугун, полностью фланцевый тройник ISO 2531/EN545, фитинги для труб из ковкого чугуна, фланцевый Тройник, фитинги из ковкого чугуна

121 674,36 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $