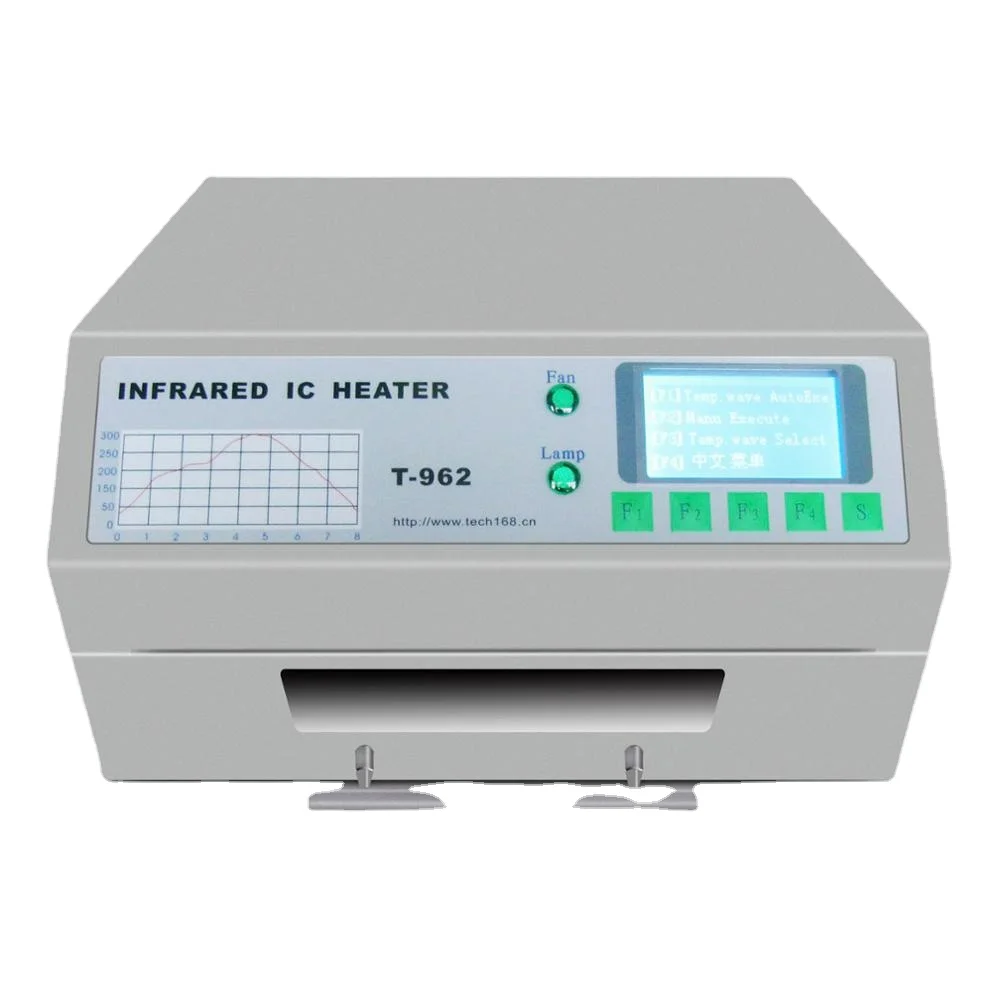

Монтажная линия Benchtop типа SMT T962 инфракрасный конвейер горячего воздуха духовка для пайки печатных плат

- Категория: >>>

- Поставщик: Wenzhou Yingxing Import&Export Co. Ltd.

Сохранить в закладки 1600569618558:

Описание и отзывы

Характеристики

Introduction

Desktop small type Reflow Oven T962 works automatically by micro-computer control. Can satisfy different type of SMD.BAG's soldering requirements.The whole soldering process were complete automatically and easy to use.

The visible drawer type workbench make whole soldering process under your surveillance automatic completed;it also can soldering the most smart small part.

Adopted a high and dependable design, make what you use gratifying and rest assured.

The visible drawer type workbench make whole soldering process under your surveillance automatic completed;it also can soldering the most smart small part.

Adopted a high and dependable design, make what you use gratifying and rest assured.

Features

(1) A big infrared soldering area

Drawer size: 180*235mm; this increases the usage range of this machine drastically and makes it an economical investment.

(2) Choice of different soldering curves

Parameters of 8 soldering curves are predefined and the entire soldering process can completed automatically from Preheat, Soak and Reflow through to cool down.

(3) Special heat up and temperature equalization designs

Drawer size: 180*235mm; this increases the usage range of this machine drastically and makes it an economical investment.

(2) Choice of different soldering curves

Parameters of 8 soldering curves are predefined and the entire soldering process can completed automatically from Preheat, Soak and Reflow through to cool down.

(3) Special heat up and temperature equalization designs

Uses up to 800 Watts of energy efficient infrared heating.

(4) Good build quality but at the same time light weight allows the T962 to be easily bench positioned transported or stored.

(5) Powerful available functions

The T962 can solder single or double-side PCB boards small parts, for example CHIP, SOP, PLCC, QFP, BGA etc.

(4) Good build quality but at the same time light weight allows the T962 to be easily bench positioned transported or stored.

(5) Powerful available functions

The T962 can solder single or double-side PCB boards small parts, for example CHIP, SOP, PLCC, QFP, BGA etc.

Part List

· 1 x T-962 Reflow Oven

· 1 x Power Line

· 1 x Power Line

Paramenters

Specification | ||

Model | T-962 | |

Heating Zone | One Zone(for desktop type) | |

Soldering Max Area | 180 x 235 mm | |

Voltage | AC220V/110V,50-60Hz | |

Mode of Heating | Infrared Tubes | |

Mode of Controlling | 8 Intelligent Temperature Curves Heating | |

Rated Power | 800W | |

Process Cycle Time | 6-8 Minutes | |

Temperature Range | 0-280℃ | |

Temperature Control Accuracy | ± 1℃ | |

Temperature Distribution Deviation | ± 2℃ | |

Dimensions | 37.5x24x37.5cm | |

Net Weight | 7KGS | |

Gross Weight | 8KGS | |

Infrared Heater

Automatic micro-computer control Infrared Heater. Adoption fast infrared radiation and circulation the wind for heat. So the temperature is very accurate and even.The non-contact output of imported high-current solid-state relays can effectively avoid damage to IC or circuit boards, making the entire welding process more scientific and safe

Eight Temperature Waves

This Reflow oven can provide eight kinds of stored temperature parameter waves as options to meet the requirements of various welding processes, and it has mobile heating and cooling functions. Besides, the entire welding process is auto-completed after you preset the wave. So you can say it is easy to use.

Wide Application

The T-962 reflow soldering machine is able to solder small parts of most PCB boards, for example, CHIP, SOP, PLCC, QFP, BGA, etc.It is the ideal rework solution from single runs to on-demand small batch production.

Packing details

Certifications

Wenzhou Yingxing Technology Co.,Ltd Specialises in SMT Production Line (PNP Machine)more than 9 years

Our Services

1.Video technical support

2.24-hour online support

3.Goods tracking support

4.Free broken parts(With 1 YEAR warranty)

2.24-hour online support

3.Goods tracking support

4.Free broken parts(With 1 YEAR warranty)

FQA

Q:How is the training?

A:After buying our machines,your engineers can go to our company or it is so easy to operate the machine according the training video and user manual,the user manual will come with the machine together.

A:After buying our machines,your engineers can go to our company or it is so easy to operate the machine according the training video and user manual,the user manual will come with the machine together.

Q:Is it hard to use these machines?

A:No,not hard at all.For our previous clients,at most 2 days is enough to learn to operate the machines.

A:No,not hard at all.For our previous clients,at most 2 days is enough to learn to operate the machines.

Q:Does your machines have quality certificate?

A:All of our machines have passed CE certificate,ISO14001(BCC),ISO9001(IQNET) and have own patent.

A:All of our machines have passed CE certificate,ISO14001(BCC),ISO9001(IQNET) and have own patent.

Q:The Warranty of the machine?

A:One year,then the parts will be free for the buyer in the warranty.

A:One year,then the parts will be free for the buyer in the warranty.

Q:English version for these machines?

A:Yes

A:Yes

Related Products

Похожие товары

Инфракрасный оплавления 5 зоны нагрева T960 Настольный SMT горячего воздуха конвейер с обратным течением волновая паяльная печь для PCB Сварки

SMT 3/4/ 6/8 10 зон оплавляемой печи Бессвинцовая печь с горячим воздухом

540 031,00 ₽

Японское производство, высокопроизводительная печь для пайки печатных плат SMT и т. Д.

Экспериментальная высокотемпературная печь для пайки, печь для оплавления

3 024 173,60 ₽ - 3 175 382,28 ₽

Аппарат для пайки

6 264 359,60 ₽

Smt оплавильная печь, 4 зоны, печь для оплавления горячего воздуха, паяльная машина, smt оплавильная печь, 12 кВт

Высококачественная печь SMD SMT MachineReflow, 8 зон, бессвинцовая духовка Reflow

Новые поступления

Новинки товаров от производителей по оптовым ценам

Японский корейский мультяшный маленький свежий самоклеящийся блокнот для заметок студенческих подписей стикеры и наклейки

Симпатичный горшок для кошек уникальный 8-дюймовый керамический растений большой бонсай со съемным блюдцем

1,38-3,06 $

Экологически чистое переработанное стекло стакан для сока и молока стеклянная бутылка воды воды/

Qtenboard 43 75 85 дюймов сенсорный экран вертикальный ЖК-панель Стенд рекламный дисплей светодиодный станок Full HD большой

648-695 $

Китайская фабрика оптовая продажа бразильский рынок коммерческий Электрический чайник нагревательная пластина для чая воды молока подогреватель

1,90-2,20 $

OEM печатная фабрика высокого качества POS бумага рулон Термобумага Jumbo Roll

600-750 $

Скользящий затвор для теплопередачи в электростанциях системах отопления и промышленных процессах погрузочно-раздвижной сыпучих материалов

750-800 $

Прямой производитель утепленная Коралловая флисовая куртка зимняя водонепроницаемая двухсторонняя теплая униформа

6,40-17,22 $