Полимер PA6 GF15 % LUMID GP2151AF инженерный пластиковый материал для литья под давлением с огнестойким покрытием разъемов PA

- Категория: >>>

- Поставщик: Suzhou Mingyu Trade Co. Limited

Сохранить в закладки 1600574843266:

Описание и отзывы

Характеристики

Detailed Features

BRAND: | LG CHEM | GRADE: | LUMID GP2151AF | ||

MATERIAL: | PA6+GF15% | ||||

FEATURES: | FLAME RETARDANT | ||||

APPLICATIONS: | CONNECTORS | ||||

FORM: | PELLETS | ||||

METHOD: | INJECTION MOLDING | ||||

Applications

APPLICATIONS

Technical Data Sheet

Properties | Test Condition | Test Method | Unit | Typical Value | |

Physical | |||||

Specific Gravity | 23℃ | ASTM D792 | - | 1.5 | |

Molding Shrinkage (Flow), 3.2mm | 23℃ | ASTM D955 | % | 0.4 ~ 0.9 | |

Melt Flow Rate | ASTM D1238 | g/10min | |||

Water Absorption | ASTM D570 | % | 0.7 | ||

Mechanical | |||||

Tensile Strength, 3.2mm | ASTM D638 | ||||

@ Break | 5mm/min | kg/cm2 | 1,200 | ||

Tensile Elongation, 3.2mm | ASTM D638 | ||||

@ Break | 5mm/min | % | 2.8 | ||

Flexural Strength, 3.2mm | 1.3mm/min | ASTM D790 | kg/cm2 | 1,600 | |

Flexural Modulus, 3.2mm | 1.3mm/min | ASTM D790 | kg/cm2 | 61,000 | |

IZOD Impact Strength, 6.4mm | ASTM D256 | ||||

(Notched) | 23℃ | kg·cm/cm | |||

-30℃ | kg·cm/cm | ||||

IZOD Impact Strength, 3.2mm | ASTM D256 | ||||

(Notched) | 23℃ | kg·cm/cm | 6 | ||

-30℃ | kg·cm/cm | ||||

Rockwell Hardness | R-Scale | ASTM D785 | - | 120 | |

Thermal | |||||

Melting Temperature | ASTM D3418 | ℃ | 220 | ||

Heat Deflection Temperature, 6.4mm | ASTM D648 | ||||

(Unannealed) | 18.6kg | ℃ | 180 | ||

4.6kg | ℃ | ||||

Coefficient of Linear Thermal Expansion | ASTM D696 | ||||

Flow | 10-5 m/m℃ | ||||

Cross-flow | 10-5 m/m℃ | ||||

Flammability | UL94 | ||||

0.75mm | class | V-0 | |||

1.5mm | class | V-0, 5VA | |||

3.0mm | class | V-0 | |||

Our Company

\\uD83D\\uDD35Founded in 2003, Suzhou Mingyu Trade Co., Limited is a diversified service company engaged in both domestic trade and international trade. Our aim is to provide customers with high-quality solutions and one-stop purchase experience. Our vision is to make plastics easier for everyone.

\\uD83D\\uDD35The company integrates world-wide famous petrochemical companies and engineering plastics company resources such as LG CHEMICAL,WANHUA CHEMICAL,SHENMA,BLUESTAR,CHIMEI, LOTTE CHEMICAL, COVESTRO, POLYONE, KOSLEN, SUZHOU RUNJIA.

\\uD83D\\uDD35Our products include general plastics, engineering plastics, special engineering plastics, toner, master batch, additives,injection mould and injection molding machines. They are widely used in automotive, household,appliances, office supplies, mobile phone accessories, routers, food and medical fields.

\\uD83D\\uDD35In order to serve customers all over the world, our company established Ever Best (HK) Limited. This company mainly focuses on international trade, and helps us to have easy access to acceptance of other currencies like European dollars.

\\uD83D\\uDD35Our customers come from more than 45 countries, like United States, Australia, New Zealand, Canada,Germany, France, Poland,Korea, Russia, Bangladesh,Vietnam, Kazakhstan, India,Ghana,Nigeria, South Africa, Egypt etc.

\\uD83D\\uDD35Our products include general plastics, engineering plastics, special engineering plastics, toner, master batch, additives,injection mould and injection molding machines. They are widely used in automotive, household,appliances, office supplies, mobile phone accessories, routers, food and medical fields.

\\uD83D\\uDD35In order to serve customers all over the world, our company established Ever Best (HK) Limited. This company mainly focuses on international trade, and helps us to have easy access to acceptance of other currencies like European dollars.

\\uD83D\\uDD35Our customers come from more than 45 countries, like United States, Australia, New Zealand, Canada,Germany, France, Poland,Korea, Russia, Bangladesh,Vietnam, Kazakhstan, India,Ghana,Nigeria, South Africa, Egypt etc.

Our Achievements

\\uD83D\\uDD35 BEST DISTRIBUTOR of LGCHEM for 3 CONSECUTIVE YEARS

\\uD83D\\uDD35 BEST SUPPLIER of BYD AUTO IN THE YEAR of 2012

\\uD83D\\uDD35 BEST SUPPLIER of BYD AUTO IN THE YEAR of 2012

\\uD83D\\uDD35 EXCELLENT SUPPLIER of ZANINI

Packing & Delivery

1. Typical Package (with pallets) 2. Typical Package (without pallets)

20 Feet Container

Package: 25kgs/bag

Net weight: 16 MT

20 Feet Container

Package: 25kgs/bag

Net weight: 17-19 MT

40 Feet Container

Package: 25kgs/bag

Net weight: 22-24 MT

40 Feet Container

Package: 25kgs/bag

Net weight: 24-25 MT

BY SEA

BY TRUCK

BY AIR

FAQ

Q:ABOUT SAMPLE

Q:ABOUT MOQ

A:The minimum quantity of an order is dependent on different types of materials, please ask our sales representatives on the left/right side.

Q:ABOUT COLOR

A:We are able to make any colors according to customer’s requirements. Customers can tell us PANTONE or RAL code directly or send us the products.

Q:ABOUT QUALITY

A:All the products we sell have tested through inspection standards, Certificate of Analysis(COA) is provided.

Q:ABOUT DELIVERY

A:We normally effect the shipment within 15 days after confirmation of order and advanced payment. It varies due to different types of plastic materials.

Q:ABOUT PAYMENT TERM

A:We accept T/T, Confirmed Irrevocable Letter of Credit and Online Deal Assured by Alibaba’s Trade Assurance.

A:5 KG of sample is allowed, but the shipping cost at the buyer’s responsibility. If more sample needed, we will refund the cost of sample in the first order (Trial order is not included).

Q:ABOUT MOQ

A:The minimum quantity of an order is dependent on different types of materials, please ask our sales representatives on the left/right side.

Q:ABOUT COLOR

A:We are able to make any colors according to customer’s requirements. Customers can tell us PANTONE or RAL code directly or send us the products.

Q:ABOUT QUALITY

A:All the products we sell have tested through inspection standards, Certificate of Analysis(COA) is provided.

Q:ABOUT DELIVERY

A:We normally effect the shipment within 15 days after confirmation of order and advanced payment. It varies due to different types of plastic materials.

Q:ABOUT PAYMENT TERM

A:We accept T/T, Confirmed Irrevocable Letter of Credit and Online Deal Assured by Alibaba’s Trade Assurance.

Contact Us

CONTACT PERSON:Livia Li

MOBILE PHONE:+86 15862380120

WHATSAPP:+86 15862380120

E-MAIL:mylq@szmychem.com

ADDRESS:ROOM 406,BUILDING 3 NO.588,

BINHE ROAD,NEW DISTRICT,SUZHOU,JIANGSU,CHINA

Похожие товары

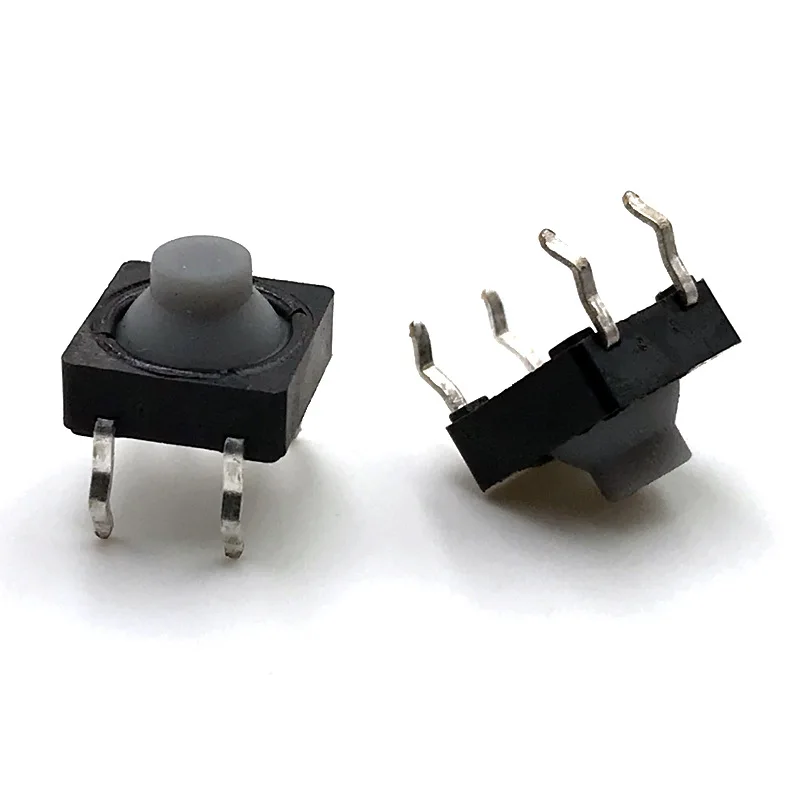

Подгонянный высококачественный TC-00107 7,8*7,8 мм силиконовый мягкий тактильный переключатель

0,02 $ - 0,06 $

L535-1 низкоскоростная центрифуга настольного малая лабораторная мельница

Производители молний на заказ, пластиковая молния, двойная открытая молния для одежды, молнии из смолы с зубцами кукурузы для одежды

0,06 $ - 0,10 $

Новое поступление, кузнечик-паук, маленькая машинка, игрушки на солнечной батарее

1,77 $ - 2,16 $

Индивидуальные брендовые кожаные сумки с большой металлической молнией

Оптовая продажа, новейший неопреновый гидрокостюм DOVOD для подводного плавания, лидер продаж, Мужской гидрокостюм для серфинга, гидрокостюм для плавания и дайвинга 7 мм

Автомобильный ЖК-измерительный приборной панели 1920*720 12 3 дюйма для системы Linux Toyota Land Cruiser 200 LC200 2008

100,00 $ - 1 190,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $