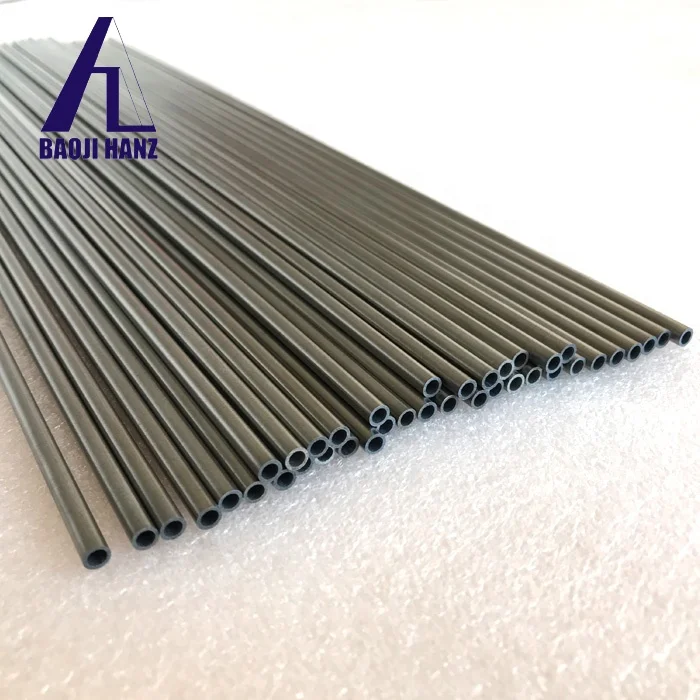

Бесшовные трубки ASTM B338 из титана и титанового сплава Gr.1 Gr. 2 г.

- Категория: Titanium >>>

- Поставщик: Liaocheng Kuncheng Pipe Co. Ltd.

Сохранить в закладки 1600576877740:

Описание и отзывы

Характеристики

ASTM B338 Covers the requirements for 22 grades of titanium and titanium alloy tubing intended for surface condensers, evaporators, and heat exchangers, as follows:

- Grade 1-Unalloyed titanium,

- Grade 2-Unalloyed titanium,

- Grade 3-Unalloyed titanium,

- Grade 7-Unalloyed titanium plus 0.12 to 0.25% palladium,

- Grade 9-Titanium alloy (3% aluminum, 2.5% vanadium)

- Grade 11-Unalloyed titanium, plus 0.12 to 0.25% palladium,

- Grade 12-Titanium alloy (0.3% molybdenum, 0.8% nickel),

- Grade 13-Titanium alloy (0.5% nickel, 0.05% ruthenium),

- Grade 14-Titanium alloy (0.5% nickel, 0.05% ruthenium),

- Grade 15-Titanium alloy (0.5% nickel, 0.05% ruthenium),

- Grade 16-Unalloyed Titanium plus 0.04 to 0.08% palladium

- Grade 17-Unalloyed titanium plus 0.04 to 0.08% palladium,

- Grade 18-Titanium alloy (3% aluminum, 2.5% vanadium) plus 0.04 to 0.08% palladium,

- Grade 26-Unalloyed titanium plus 0.08 to 0.14% ruthenium,

- Grade 27-Unalloyed titanium plus 0.08 to 0.14% ruthenium,

- Grade 28- Titanium alloy (3% aluminum, 2.5% vanadium) plus 0.08 to 0.14% ruthenium,

- Grade 30-Titanium alloy (0.3% cobalt, 0.05% palladium),

- Grade 31-Titanium alloy (0.3% cobalt, 0.05% palladium),

- Grade 33-Titanium alloy (0.4% nickel, t0.015% palladium, 0.025% ruthenium, 0.15% chromium),

- Grade 34-Titanium alloy (0.4% nickel, 0.015% palladium, 0.025% ruthenium, 0.15% chromium),

- Grade 35- Titanium alloy (4.5% aluminum, 2% molybdenum, 1.6% vanadium, 0.5% iron, 0.3% silicon),

- Grade 36- Titanium alloy (45% niobium).

Standard: ASTM B338, ASTM B337, ASME SB337.

Description Name: ASTM B338 Titanium Gr.2 welded pipes, ASTM B338 Titanium Gr.2 seamless pipes, ASTM B338 Titanium Gr.2 welded tubes, ASTM B338 Titanium Gr.2 seamless tubes, Titanium Alloy Grade 2 seamless pipes, Titanium Alloy Grade2 welded pipes, Titanium alloy tubing.

Size: 6mm to 610mm.

Schedules: 10s, 20, 40s, 40, 60, 80s, 80, 100, 120, 140, 160, XXS.

Type: Seamless / ERW / Welded / Fabricated.

Wall Thickness: 1mm to 50mm.

Shape: Round, Square, rectangular.

Length: Single random length. / Double random length or as customer’s actual request. Max length 12000mm.

Referenced Documents:

ASTM Referenced Standards

A370 Test methods and Definitions for mechanical testing of steel products.

E8 Test methods for tension testing of metallic materials.

E29 practice for using significant digits in test data to determine conformance with specifications.

E120 Test Methods for chemical analysis of titanium and titanium alloys.

E1409 Test method for determination of oxygen in titanium and titanium alloys by the inert gas fusion technique.

E1447 test method for determination of hydrogen in titanium and titanium alloys by the inert gas fusion thermal conductivity method.

Chemical Composition:

| Element | Composition % | |||||

| Grade 1 | Grade 2 | Grade 3 | Grade 7 | Grade 9 | Grade 11 | |

| Nitrogen, max | 0.03 | 0.03 | 0.05 | 0.03 | 0.03 | 0.03 |

| Carbon, max | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

| Hydrogen, max | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 |

| Iron, max | 0.2 | 0.3 | 0.3 | 0.3 | 0.25 | 0.25 |

| Oxygen, max | 0.18 | 0.25 | 0.35 | 0.25 | 0.15 | 0.15 |

| Aluminum | … | 2.5-3.5 | 2.5-3.5 | |||

| Vanadium | … | 2.0-3.0 | 2.0-3.0 | |||

| Tin | … | |||||

| Ruthenium | … | |||||

| Palladium | … | 0.12-0.25 | ||||

| Cobalt | … | |||||

| Molybdenum | … | |||||

| Chromium | … | |||||

| Nickel | … | |||||

| Niobium | … | |||||

| Zirconium | … | |||||

| Silicon | … | |||||

| Residuals, max each | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Residuals, max total | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Titanium | balance | balance | balance | balance | balance | balance |

Tensile Requirements

| Grade | Tensile strength, in | Yield Strength, 0.2% Offset | Elongation in 2 in. or 50mm, min, % | ||||

| Ksi | Mpa | min | max | ||||

| Ksi | Mpa | Ksi | Mpa | ||||

| 1 | 35 | 240 | 25 | 170 | 45 | 310 | 24 |

| 2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| 3 | 65 | 450 | 55 | 380 | 80 | 550 | 18 |

| 7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

| 9 | 125 | 860 | 105 | 725 | … | … | 10 |

| 11 | 35 | 240 | 25 | 170 | 45 | 310 | 24 |

Flattening Test

Tubing shall withstand, without cracking, flattening under a load applied gradually at room temperature until the distance between the load platens is not more than H in. H is calculated as SB338 standard.

Flaring Test

For tube 3 1/2 in.(88mm) in outside diameter and smaller, and 0.134 in.(3.4mm) in wall thickness and thinner, a section of tube approximately 4 in.(102mm) in length shall withstand being flared with a tool having a 60°included angle until the tube at the mouth of the flare has been expanded in accordance with table4 the flared end shall show no cracking or rupture visible to the unaided eye. Flaring tests on larger diameter tube or tubing outside the range of standard shall be as agreed upon between the manufacturer and the purchaser.

Hydrostatic or Nondestructive Testing

Welded tubing shall be tested using both a nondestructive electromagnetic test and an ultrasonic test as described in standard. Seamless and welded/cold worked tubing shall be tested using an ultrasonic test as described in standard.

Welded or seamless tubing shall be tested with a hydrostatic or pneumatic test as described in standard. Other requirements details can check standard.

we're passionate about manufacturing some of the best precision tubes in the world, and our experience has made us a leader in the field.

What’s unique about us as a manufacturer is that we have the capability to manufacture both seamless and welded tubes, in a wide range of stainless steel, nickel, titanium and zirconium alloys. This gives our customers great product flexibility with the choice between straight lengths or coils. Whatever application you have in mind, we’ll do our utmost to meet and surpass your expectations.

PH:008613184174934

Похожие товары

Многофункциональная медицинская титановая

ASTM B861 GR2 GR5 бесшовная титановая труба для

Китай оптовая продажа суперэластичная трубка nitinol из титанового никелевого сплава

Титановый электрод с ИК-покрытием Ru для удаления накипи циркулирующей

Немагнитные Iso-5832-2 солнечного коллектора Gb/T2965-2007 титана Grade 2

Суперэластичный нитиноловый сплав с эффектом памяти, низкотемпературный суперэластичный нитиноловый сплав, медицинский нитиноловый сплав

Astm B348 круглый титановый стержень Gr 1 2 5 7 8 12

Новые поступления

Новинки товаров от производителей по оптовым ценам