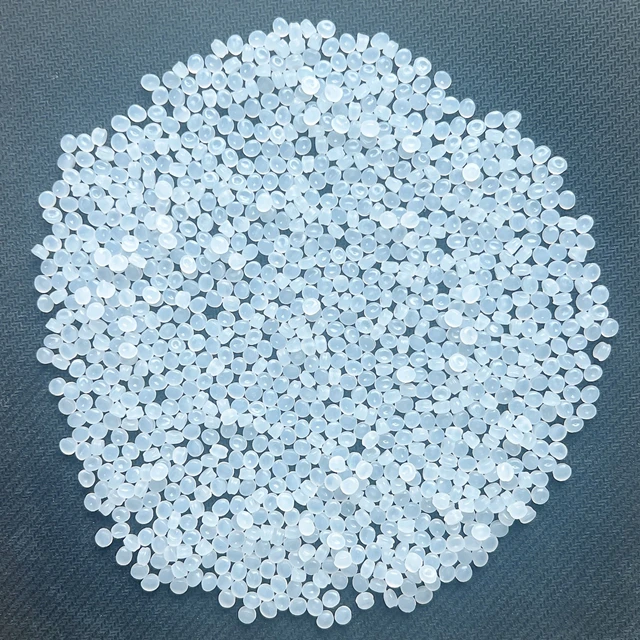

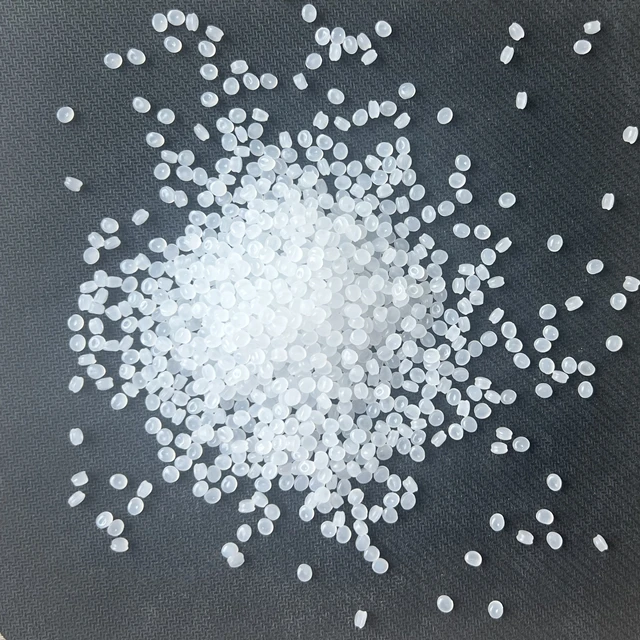

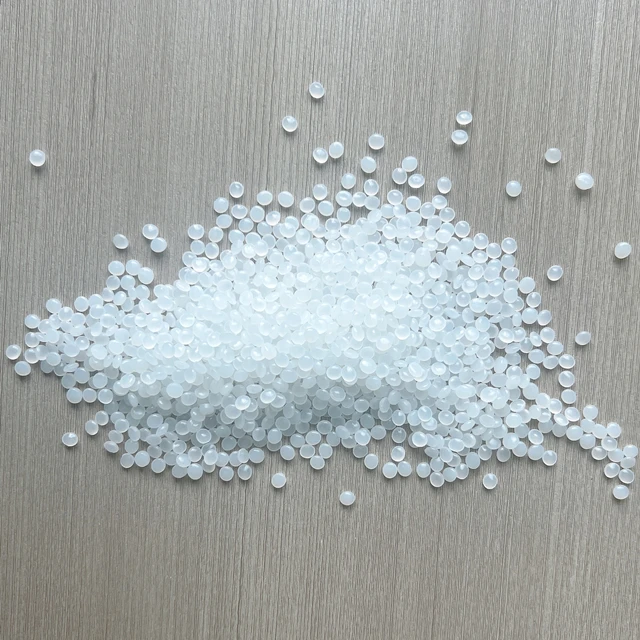

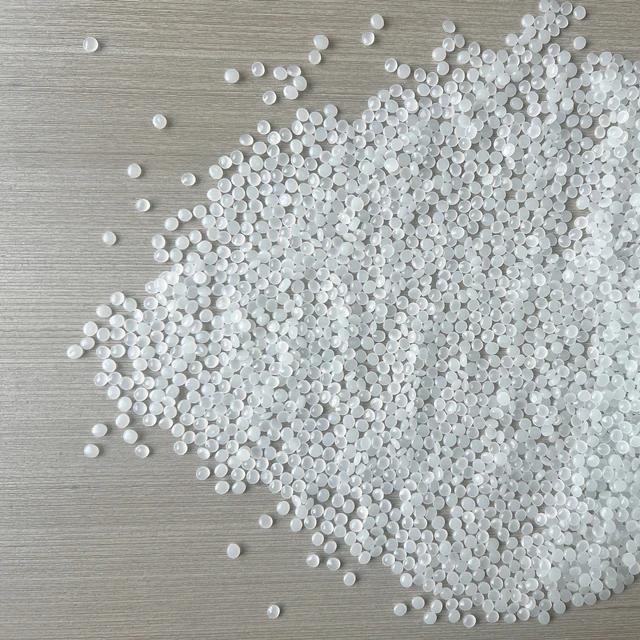

Большое количество поставок ldpe смола сырые гранулы девственная Смола гранулированный

- Категория: LDPE >>>

- Поставщик: Hangzhou Yuhang Trade Co. Ltd.

Сохранить в закладки 1600581481727:

Описание и отзывы

Характеристики

Product Description

Material status | Circulation is normal | ||||||

features | Easy to process, insulated, transparent and non-toxic | ||||||

use | Packaging film, sheet and cable | ||||||

Processing method | Film blowing and extrusion | ||||||

form | The particle | ||||||

Physical properties of | The test conditions | Attribute values | unit | The test method | |||

Investment refers to | -- | 1.8 to 3.2 | g/10 min | ASTM D1238 | |||

The density of | -- | 0.919 to 0.923 | kg/m³ | ASTM D1505 | |||

cleanliness | -- | ≤10 | g/kg | There is no | |||

turbidity | -- | ≤11 | % | There is no | |||

Mechanical properties of | |||||||

The tensile strength | -- | ≥9 | MPa | ISO 527 | |||

Elongation at break | -- | ≥500 | % | ISO 527 | |||

Optical performance | |||||||

Tear strength | The transverse | ≥10 | N/mm | ISO 6383 | |||

Product overview

High pressure low density polyethylene (HP-LDPE, short for LDPE) has been industrialized for more than 70 years, although with the discovery and development of olefin polymerization catalyst, the variety and yield of polyethylene has made great progress. But high pressure polyethylene still plays an important role. Ethylene is polymerized into high molecular weight polyethylene by free radical mechanism at high temperature and high pressure, which has the following characteristics:

(1) Ethylene polymerization is an intense exothermic process. The polymerization heat of ethylene is about 93.5kJ/mol (or 3.3kJ/g), and the specific heat capacity of ethylene is 2.51~2.85J/(g·℃) at 235MPa and 150~300℃. If the reaction heat cannot be removed in time, the temperature will increase by 12~13℃ for every 1% of ethylene polymerization. If the temperature is too high, it can also cause the ethylene to break down.

(2) Under high pressure, ethylene has been compressed to a density of 0.5g/mL gas tight phase state, similar to the liquid can no longer be compressed, at this time, the distance between ethylene molecules is significantly shortened, thus increasing the collision probability of free radicals and ethylene molecules, so it is easy to occur polymerization reaction.

(3) At high temperature, the free radical activity of the growing chain is high, and chain transfer reaction is easy to occur. The polymer obtained is linear structure with many branched chains. Usually there are 20~30 branch chains per 1000 carbon chain atoms, the crystallinity is 45%~65%, the density is 0.910~0.925g/mL, light weight, flexible, low temperature resistance, impact resistance is good.

(1) Ethylene polymerization is an intense exothermic process. The polymerization heat of ethylene is about 93.5kJ/mol (or 3.3kJ/g), and the specific heat capacity of ethylene is 2.51~2.85J/(g·℃) at 235MPa and 150~300℃. If the reaction heat cannot be removed in time, the temperature will increase by 12~13℃ for every 1% of ethylene polymerization. If the temperature is too high, it can also cause the ethylene to break down.

(2) Under high pressure, ethylene has been compressed to a density of 0.5g/mL gas tight phase state, similar to the liquid can no longer be compressed, at this time, the distance between ethylene molecules is significantly shortened, thus increasing the collision probability of free radicals and ethylene molecules, so it is easy to occur polymerization reaction.

(3) At high temperature, the free radical activity of the growing chain is high, and chain transfer reaction is easy to occur. The polymer obtained is linear structure with many branched chains. Usually there are 20~30 branch chains per 1000 carbon chain atoms, the crystallinity is 45%~65%, the density is 0.910~0.925g/mL, light weight, flexible, low temperature resistance, impact resistance is good.

Application field

Application range of low density polyethylene: suitable for seasoning, pastry, sugar, preserves, biscuits, milk powder, tea, fish floss and other food packaging. Pharmaceutical tablet, powder and other packaging, shirts, clothing, knitted cotton products and chemical fiber products and other fiber products packaging. Washing powder, detergent, cosmetics and other daily chemical products packaging. Because of the poor mechanical properties of single-layer PE film, it is usually used as the inner layer of composite packaging bag, that is, multi-layer composite film heat sealing base material.

Похожие товары

PP/LDPE copolyme/гомополимерные пластиковые гранулы литьевая

1 000,00 $ - 1 200,00 $

Оптовая продажа пластиковых сырья MLLDPE

4,50 $ - 6,50 $

Чистый черный полиэтилен высокой плотности HDPE гранулы PE100 PE80 для

0,89 $ - 1,20 $

Полиэтиленовая Смола низкой плотности пленочное Сырье

Sabic lldpe 118w 118wj 218w 218wj/lldpe гранулы для геомембраны/sabic-lldpe

Прозрачная пленка LDPE/перерабатываемый Пластиковый лом LDPE/пленка

В наличии Китай Заводская поставка пленочные гранулы

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $