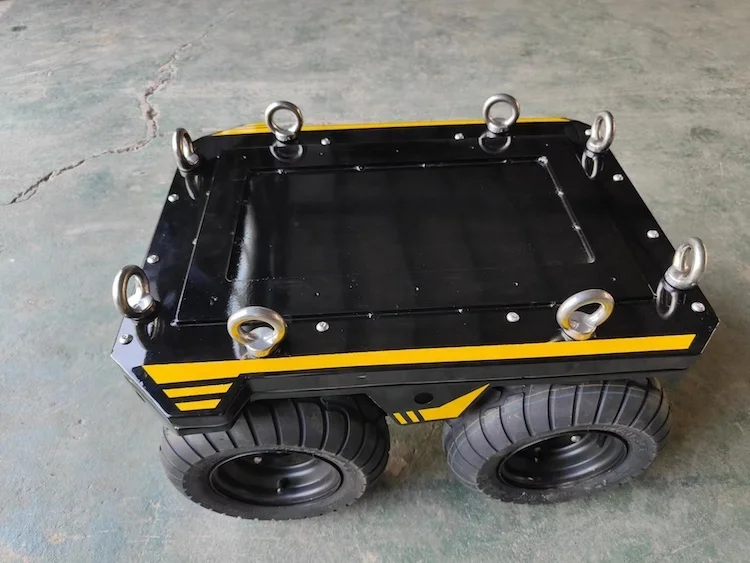

Робот шасси с дистанционным управлением

- Категория: >>>

- Поставщик: Shanghai Kymoon Rubber Co. Ltd.

Сохранить в закладки 1600587982834:

Описание и отзывы

Характеристики

We can customize various tracked chassis undercarriage systems tracked chassis and the loading capacity can up to 10tons. They have been widely used for construction machinery, agriculture machines, gardening machinery, ,wheelchair,drilling machinery, engineering machinery, mining colliery etc.

Tyre Wheels drived chassis:

Length(mm) | Width(mm) | Height(mm) | Off From Ground(mm) | Electric motor | Slef-Weight(kgs) | Load bearing | Speed |

700 | 600 | 400 |

| 66 | kgs | Kilo meter/H |

Type of rubber tracks:

1, Bolt on type

2, Bolt on type with steel bottom

3, Chain ontype

4, Clip on type

5, Pavers rubber pad

Rubber tracked chassis specification as below:

Length(mm) | Width(mm) | Height(mm) | Off From Ground(mm) | Electric motor | Slef-Weight(kgs) | Load bearing | Speed |

700 | 600 | 400 |

| 66 | kgs | Kilo meter/H |

Ps.: Controller + Remote Control

Customized Color Available

Usage: all

Rubber track chassis payload 100kgs rubber track with motor, controler, 2.4G Remote Control/crawler robot undercarriage

The feature of rubber tracks:

(1). Less round damage

Rubber tracks cause less damage to roads than steel tracks, and less rutting of soft ground than either steel tracks of wheel products.

(2). Low noise

A benefit to equipment operating in congested areas, rubber track products less noise than steel tracks.

(3). High speed

Rubber track permit machines to travel at a higher speed than steel tracks.

(4). Less vibration

Rubber tracks insulate machine and operator from vibration, extending the machine's lifetime and lowering operate fatigue.

(5). Low ground pressure

The ground pressure of rubber tracks equipped machinery can be fairly low, about 0.14-2.30 kg/ CMM, a major reason for its use on the wet and soft terrain.

(6). Superior traction

The added traction of rubber, track vehicles permits them to pull twice the load of wheel vehicles of the sane weight.

Похожие товары

Оригинальный оригинальный MAHLE поршневой IMPA882500/4JG1 комплект вкладышей Ремонтный инженер сделано в Японии

Переднее колесо экскаватора EC80 ECR88 прямые продажи от производителя

Генератор 0124555129 BOSCH VOLVO 11170321 DEUTZ 01182771 04284845 MAHLE MG1128 fmgg800t

Точка отливки зубьев EC360RC зубья ковша T55RC инструменты для заземления экскаватора 14553243RC

V360Z 60 50 EC460RC литье из легированной стали зубец ковша для экскаватора прочный и устойчивый к коррозии

Двигатель Swafly D13F в сборе для Volvo дизельный двигатель

Высокое качество EX35 зубья ковша литье PC200 для колесного погрузчика

Новые поступления

Новинки товаров от производителей по оптовым ценам