Пневматический Трафаретный очиститель печатных плат аппарат для очистки с соплом SMT промышленный ультразвуковой пылесос

- Категория: >>>

- Поставщик: Shenzhen Oubel Technology Co. Ltd.

Сохранить в закладки 1600607458792:

Описание и отзывы

Характеристики

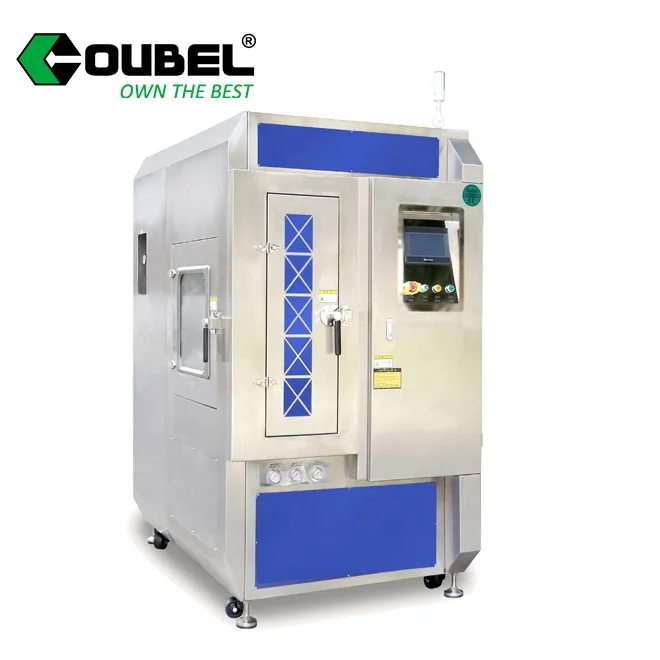

Pneumatic Stencil PCB Cleaner machine SMT Nozzle PCBA Cleaning Machine Industrial Ultrasonic Vacuum Cleaner For PCB Board

Features:

1.Fully automatic cleaning mode: when the equipment is in operation, the workpiece moves in the washing basket with the washing basket back and forth. The high-pressure jetting and heating cleaning liquid of the spray system can make the PCBA realize the whole process of automatic cleaning, rinsing and drying in all directions;

2.The whole process visualization: visualization window and LED light device, the cleaning process at a glance;

3.The most scientific nozzle design (patent): the use of up and down dislocation, left and right gradually increasing distribution, completely covering the cleaning blind zone. The spray arm and nozzle are detachable;

4.Visual nozzle pressure can be adjusted: It solves the collision and splash problem of small workpiece size under high pressure spray condition during cleaning;

5.The photoelectric sensor switch installed in the window protects the personal safety. The standard dilution tank/rinsing tank heating system greatly improves the cleaning efficiency and shortens the cleaning time;

6.The fuselage village quality: the overall 304 stainless steel body. Acid, alkaline and other cleaning fluid;

7.Comprehensive cleaning system: compatible with running water or chemical cleaning, for SMT; Thoroughly cleaning the surface residual rosin, water-soluble flux, no-clean flux / solder paste and other organic and inorganic pollutants after welding by THT PCBA;

8.The built-in filter device for cleaning can realize the recycling of solvent and reduce the amount of solvent;

9.There is an emergency stop button and leakage protection function;

10.Lower operating costs: lower equipment investment costs, localized services, teams and adequate spare parts supply.

Product Name | Offline PCB Cleaner Industrial Ultrasonic Cleaning Machine With Factory Price |

Model | OB-C800 |

Dimensions | 1300mm(L) ×1400mm(W) × 1950mm(H) |

Size in cleaning area | 650mm(L) ×600mm(W) ×160mm(H) 3 layers |

Power / air source | Three-phase five-wire system, 380V/15Kw (rated power) / 0.45Mpa-0.7Mpa |

Spray tank capacity | 20L |

Heater power | 9KW |

Cleaning time | 0~99 mins (adjustable) |

Cleaning temperature (liquid) | Normal temperature —75 ° C (adjustable) |

Rinsing time | 1 minute / time (1-59 times / adjustable) |

Rinsing temperature (DI water) | Normal temperature —55 ° C (adjustable) |

Drying time | 0~99 mins (adjustable) |

The monitoring range of the resistivity meter | 0~18MΩ |

Packing Details :Plywood case, for export!

Port:Shenzhen

Delivery Details : 20-25 days

Oubel supplies the dispensing and PCB conformal coating machine, SMT &DIP machines that is supported by a global service network ,we offer customer-inspired solutions in a range of industries.OUBEL is dedicated to making quality products that help our clients operate more efficiently and effectively. Oubel is guided by the principles of fairness to our suppliers, associates, clients and employees, and helping them achieve to the best of their potential.

Company

Studio

Over the years, we have developed core competencies that warrant us to be the global leader in the industry: Customization , Short lead time , Flexibility , Customer Satisfaction , Premium Quality Products , Value For Money , International Distribution Network , Extensive Service Support.To maintain customer satisfaction through timely delivery of reliable products and servicesTo maintain an efficient and quality driven work environment with an emphasis on constant Research and Development to provide technologically superior products.To attract and retain quality personnel through an equitable reward system, constant training and upgrading of skills as well as career enhancement opportunities

Core Competencies

Corporate Objectives

Since its establishment, the company has established good business relations with traders from all over the world and won the favor of many customers with our high-quality products and services

When the customer comes to the factory to watch the production and operation of the machine, our team carefully explains the operation process of the machine for him, so that the customer has some understanding of our production process and can rest assured of our products.

Respond in time

Your inquiry about our products and price will be replied within 24 hours

Cheap and fine

We provide you with high quality materials and competitive prices

Good communication

Well-trained and experienced staffs to answer your enquires in fluent English

High efficiency

Complete the production shipment in the shortest time

High quality

Strict QC before shipping the products,Responsible for the quality of all products

Wide range of services

OEM & ODM services offered,Meet all your needs

Q: What we can do for you?

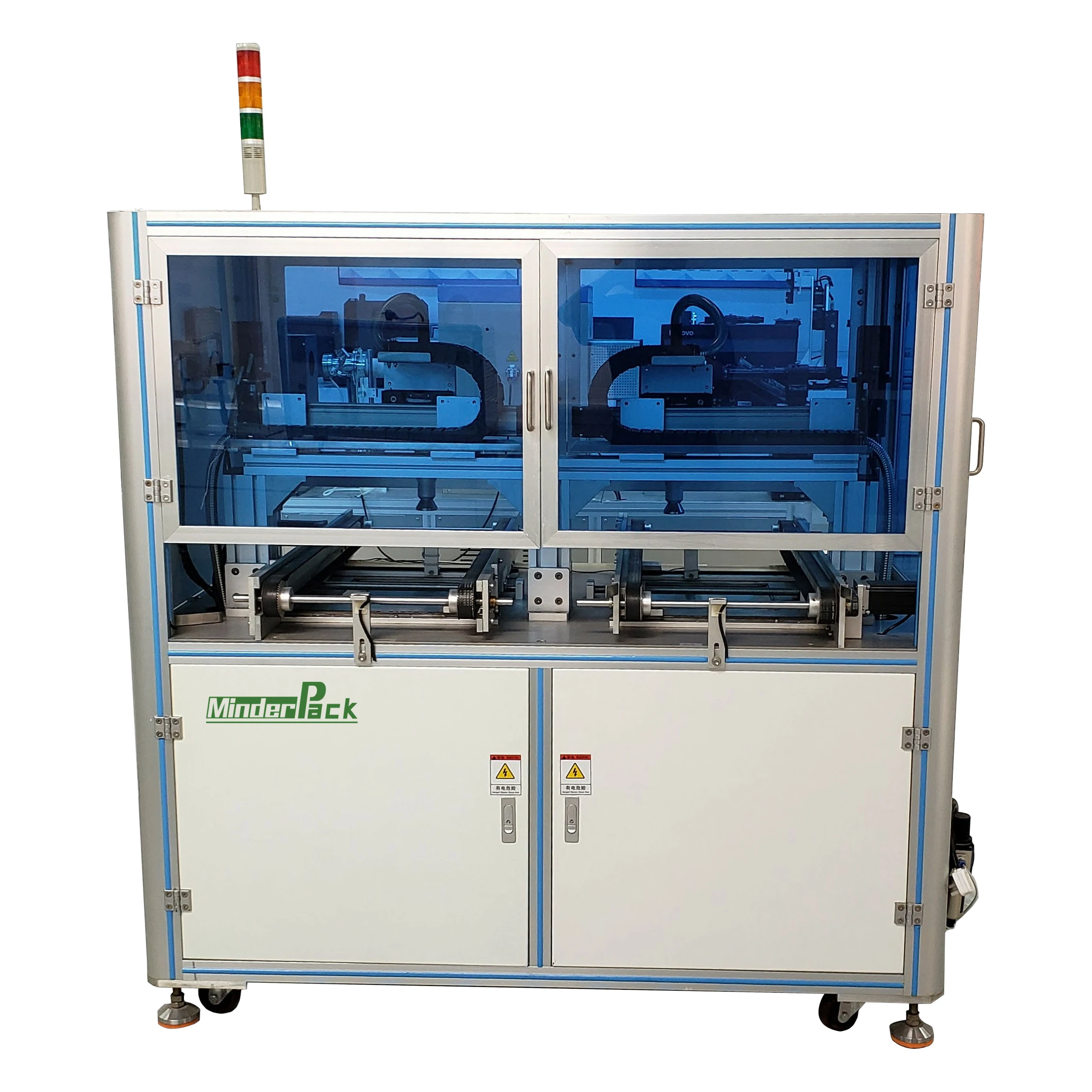

A: We provide SMT&DIP machine,we can aslo provide Production line scheme,such as Whole coating line,SMT line,DIP line and so on.Professional Technical Support and Service.

Q: What is your delivery date?

A: The delivery date is about 20-25 working days after receive the payment.

Q: What is your payment terms?

A: TT 100% payment in advance.

Q:This machine is easy to use ? if I have no experience, I can also operate it well ?

A:Yes, our machine is designed to use easily, Normally it will take you 1 day to learn how to operate, if you are a technician, it will much faster to learn.

Q:Do you provide the user manual and operating videos to support us ?

A:We will provide the English user manual for free , and the operation video is available.Our software is all English.

Q: If we come to your factory, you will provide the free training ?

A:Yes, warmly welcome you to visit our factory, we will arrange the free training for you.

Q:What service you can provide when we have some problem during the operation?

A:We can invite our engineers to your company for guidance, but you are responsible for the air tickets and accommodation,we can also provide remote guidance

Q:What is the payment way ?

A:We accept the payment terms: T/T, WesterUnion, Moneygram, Paypal, etc.

Похожие товары

Лучшая цена, малогабаритные сушилки для очистки пола

Отличное качество низкая цена машина для очистки плитки промышленный пол скруббер сушилка

Вращающаяся сушилка для ковровых покрытий, Центробежная Машина для ковровых покрытий RL 1400 T 320 см, устройство для отжима ковровых покрытий, амортизирующие колеса

Небольшая стиральная машина для чистки плитки машина для чистки скруббер сушилка

Автоматический скруббер для уборки в супермаркете

Бренд Maoquan, 2024, промышленная электронная сушилка для чистки пола для садовых гостиничных супермаркетов

Популярная фабрика прямых продаж коммерческих пол стиральная машина сушилка

Новые поступления

Новинки товаров от производителей по оптовым ценам