Автоматическое оборудование для сборки крышки аккумулятора LFP нестандартное Индивидуальное от производителя

- Категория: >>>

- Поставщик: Shandong Huiyao Laser Technology Co. Ltd.

Сохранить в закладки 1600608542004:

Описание и отзывы

Характеристики

Product Description

Equipment introduction

1. Equipment function:

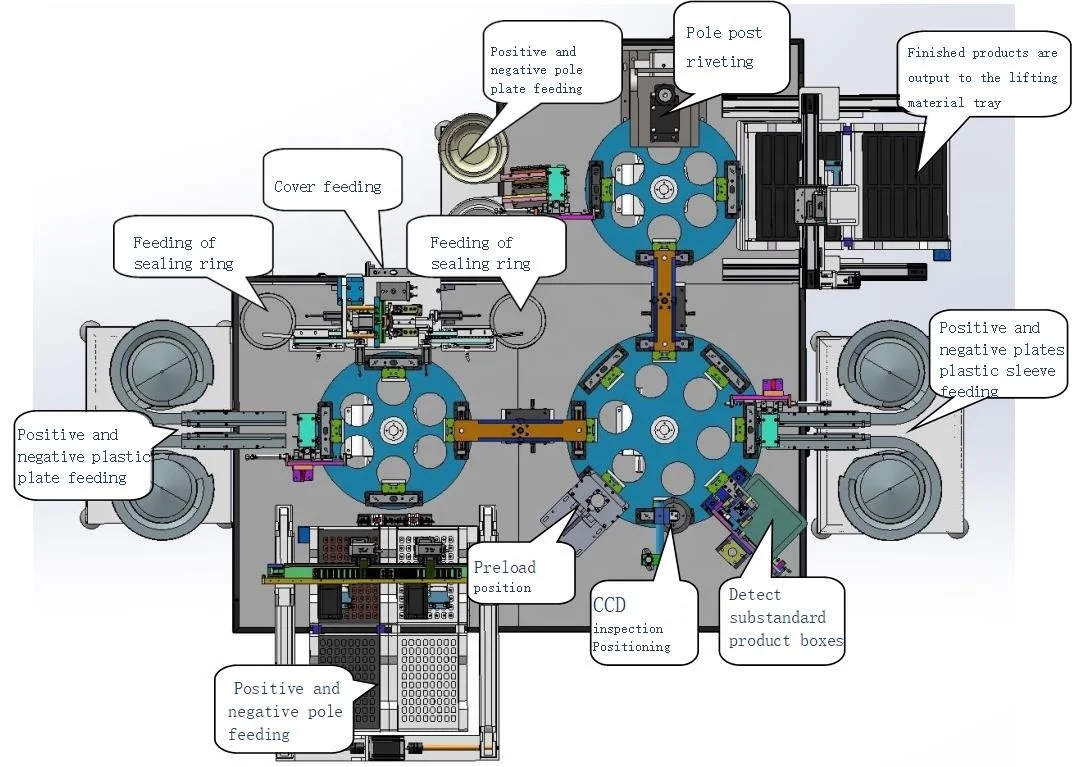

The equipment can complete the automatic assembly and pressure riveting of the positive and negative poles, plastic sheets, rubber sealing rings, cover plates, plastic sleeves, and positive and negative plates of the battery cover plate. After the pressure riveting is completed, the cover plate is grasped by the manipulator. into the lifting plastic material tray. (The sealing rubber ring installed in the cover plate can be confirmed by photographing with CCD. If the installation is not good, the subsequent installation and pressure riveting will not be carried out. Reduce labor, effectively improve production efficiency, and eliminate the instability of manual assembly to products. The machine can be operated by one to two people.

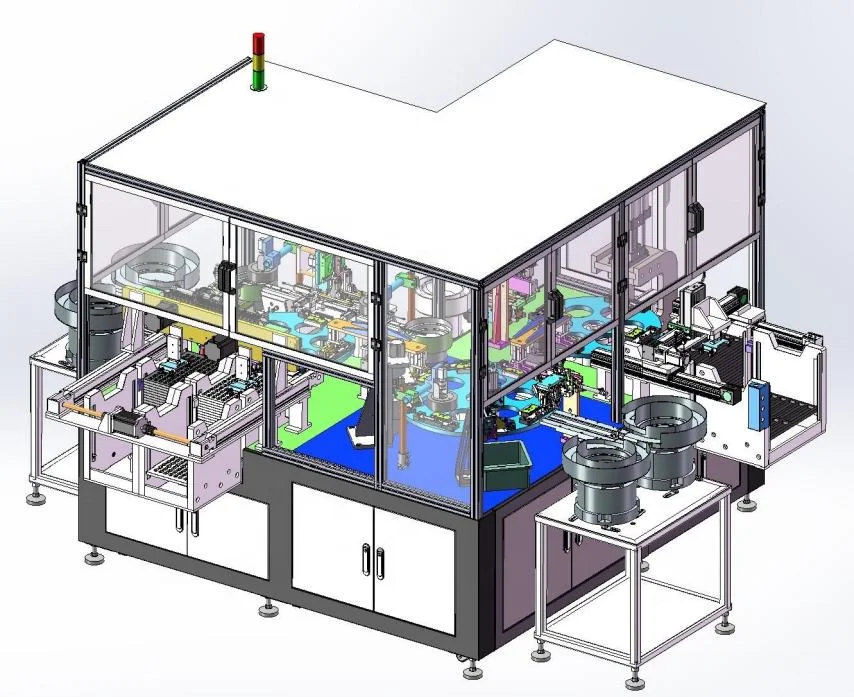

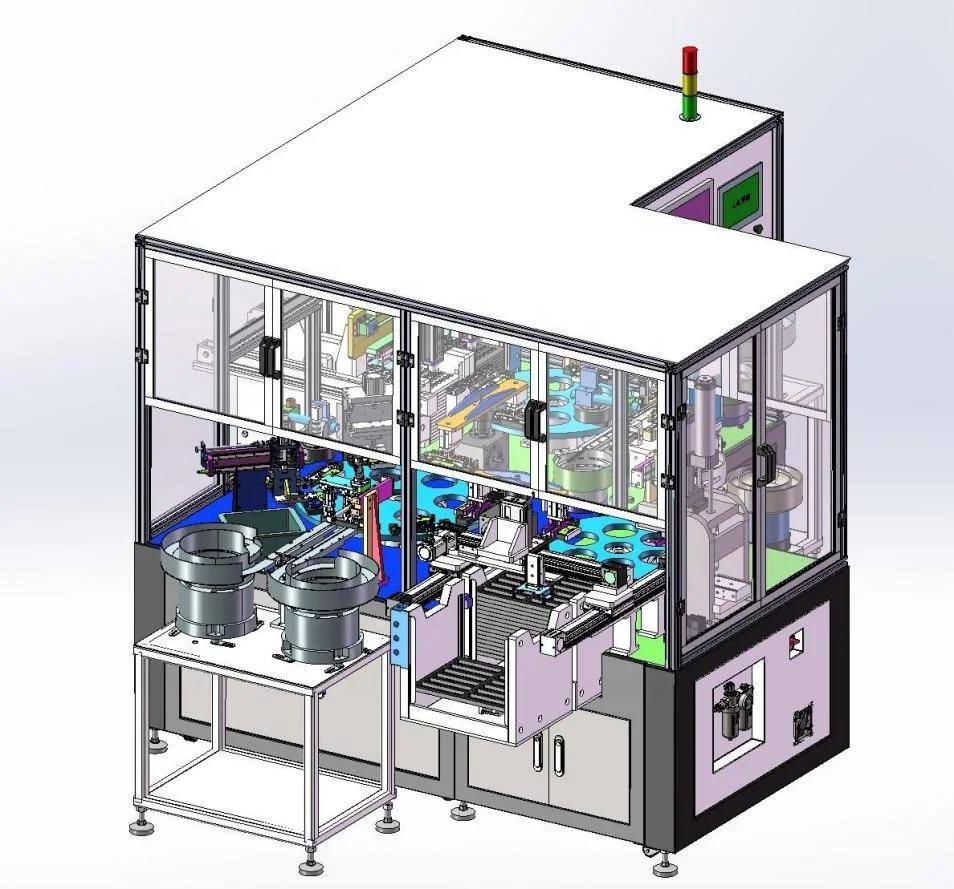

2. Appearance of the device:

The device shape may vary due to customer requirements and technical refinement.

3. Introduction of equipment process:

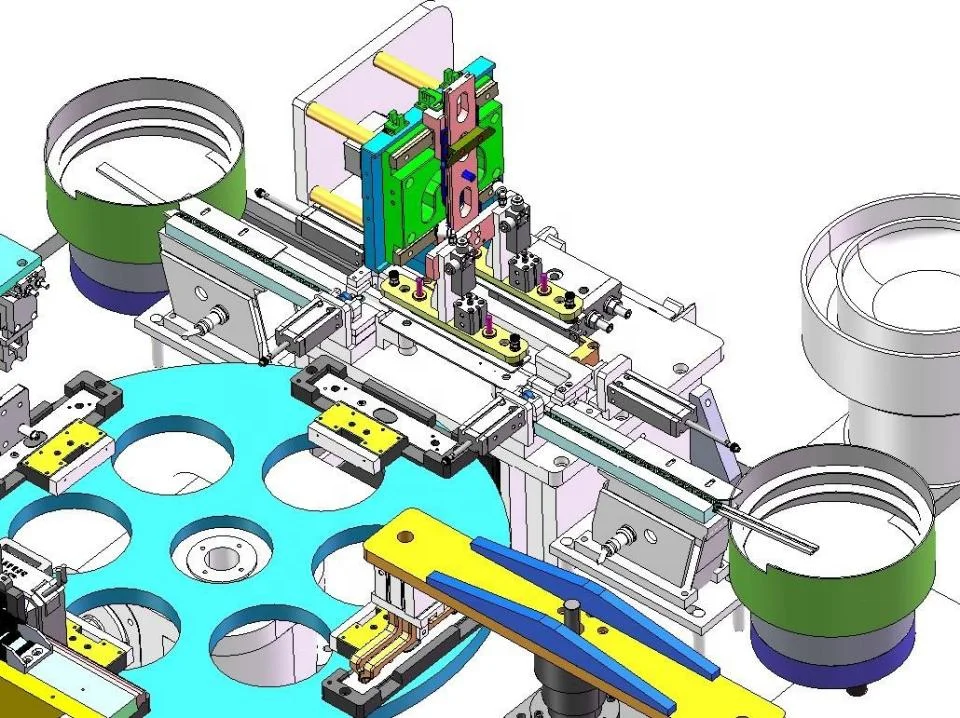

The equipment mainly adopts three cam divider mechanisms for cyclic installation and feeding and discharging of each process. The use of multiple cam dividers and smaller turntables can improve the rotation accuracy of the turntable and reduce the inertia during rotation, which is conducive to improving the assembly accuracy of the cover plate. Work speed with turntable rotation improves efficiency. The positive and negative poles are stacked on full-page material trays to reduce the number of manual replacement of materials and improve the efficiency of the automatic assembly machine; the servo motor drives and cooperates with the manipulator to grab the positive and negative poles to the positioning place, and then the manipulator transmits them to the positive and negative poles after positioning. The installation position of the negative pole; the positive and negative plastic plates are fed by a vibrating disc with a manipulator for loading and unloading; the cover plate is automatically fed by a two-station rotary mechanism feeder, and the rubber sealing ring is fed by a vibrating disc. It is then transferred to the installation station by the manipulator for installation; the pre-compression mechanism reliably compresses the installation of the previous process; (after compression, the CCD lens takes a picture of the cover to confirm whether the installation of the rubber sealing ring is qualified or not, this is optional ); the positive and negative plates are loaded by the vibrating plate; the positive and negative plates are automatically fed by the vibrating plate; after the accessories are installed, the pressure mechanism rives the cover plate; the assembled product is grasped by the robot to lift and stack Material tray. After the tray is full, it is transferred to a laser welding process, which greatly reduces the labor intensity of operation and improves the production efficiency of cover plate assembly.

Detailed introduction of the functions of each process of the equipment

1. Positive and negative pole column tray feeding:

The feeding process adopts stacked tray feeding. The double manipulators grab the positive and negative poles respectively, put them in the positive and negative poles for positioning, and then grab the manipulators into the installation station fixture on the turntable.

The positive and negative plastic plates are fed by a vibrating disc, and the vibrating disc can identify the front and back and front and rear positions. The material sent out by the vibrating plate reaches the material level, and after precise positioning, the material is grabbed by the manipulator and installed on the positive and negative poles in the fixture of the turntable installation station.

In this process, after the cover plate and the rubber sealing ring are positioned and guided and installed, they are mechanically grabbed and installed on the positive and negative pole plates in the divider turntable fixture. The rubber sealing ring is supplied by a vibrating plate, and the cover plate is supplied by a rotating two-station turntable. The motor jacking mechanism and the manipulator realize the jacking and feeding.

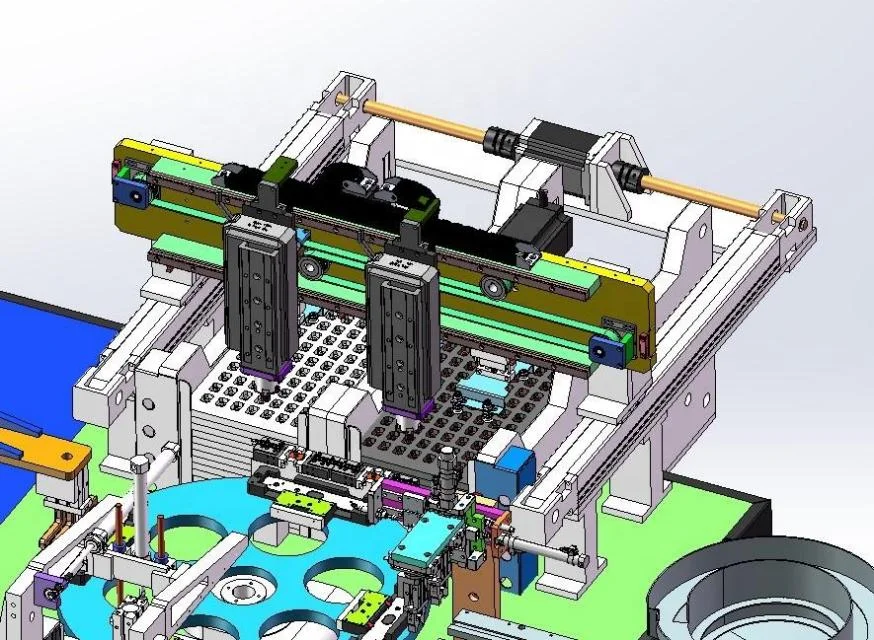

It is mainly to compress the situation that may not be completely installed in the previous process, so that the installed accessories are in place.

5. CCD camera detection:

CCD camera detection, mainly to check whether the rubber sealing ring is installed in place. The qualified materials are checked for the next process. If the materials are unqualified, the next assembly position of the materials will be grabbed by the robot into the unqualified material box.

The plastic sleeves of the positive and negative plates and the positive and negative plates are fed by vibrating discs. After reaching the material level, they are precisely positioned.

The manipulator grabs and installs the installed object in the installation station fixture on the cam divider turntable.

The manipulator grabs and installs the installed object in the installation station fixture on the cam divider turntable.

7. Riveting mechanism:

The riveting mechanism is to use a 3-ton gas-liquid booster cylinder to rive the material that has been installed in place.

Mechanical structure

The bottom frame of the machine is welded with a 50*50 square tube, and the platform support is welded with square iron blocks and is milled by a gantry before installing the platform plate.

Control System

The cover plate automated assembly system is controlled by plc and uses a 10-inch touch screen. CCD inspection systems use 19 to 21 inch displays.

Specification

XYZ Travel | Customizable |

R Axis | Optional, 360° rotation |

Position Accuracy | ±0.02mm |

Repeatability Accuracy | ±0.01mm |

Motion Source | Step motor or Servo motor |

Max Speed | 500mm/s |

Cooling Method | Water cooling |

Electricity Demand | Customizable |

Laser Wavelength | 1080nm |

Observation Syatem | CCD system |

Gas Protection | Optional, Argon, Nitrogen |

Environmental Requirements | No vibration, interference and ventilation |

Welding Penetration | 0.1~3.0mm |

MOQ | 1 set |

Company Profile

Shandong Huiyao Laser Technology Co., Ltd. focuses on the R & D, manufacturing, marketing and service of industrial laser processing equipment. Focusing on laser welding for more than ten years, the company has integrated advanced laser technology and products at home and abroad, implemented strong cooperation, and built an independent innovation platform for science and technology; provided customers with high-quality products and customized solutions, and continued to create the maximum value for customers.

Shandong Huiyao Laser Technology Co., Ltd. has a staff team which owns high-level culture and high-tech level,senior marketing management team,excellent engineering and technical personnel, bridle-wise service engineer, forming a strong technical support system. Our development system is perfect, adhere to indigenous innovation,brand management and spare no effect to create professional、superior、safe、normative and classic products. Not only meet the demands that customers on the scale, quality and efficiency, but also satisfy personalized design and manufacturing requirements.

Shandong Huiyao Laser Technology Co., Ltd. depends on the quality as life , integrity as foundation of the enterprise, we

pursue"quality is first, reputation is important, management is fundamental,service is sincere"as company objectives, look "strive for excellence, purse for remarkable" as policy, dedicate social sincerely. Warmly welcome all the friends cooperation together,to create a great future.

Shandong Huiyao Laser Technology Co., Ltd. has a staff team which owns high-level culture and high-tech level,senior marketing management team,excellent engineering and technical personnel, bridle-wise service engineer, forming a strong technical support system. Our development system is perfect, adhere to indigenous innovation,brand management and spare no effect to create professional、superior、safe、normative and classic products. Not only meet the demands that customers on the scale, quality and efficiency, but also satisfy personalized design and manufacturing requirements.

Shandong Huiyao Laser Technology Co., Ltd. depends on the quality as life , integrity as foundation of the enterprise, we

pursue"quality is first, reputation is important, management is fundamental,service is sincere"as company objectives, look "strive for excellence, purse for remarkable" as policy, dedicate social sincerely. Warmly welcome all the friends cooperation together,to create a great future.

Company Advantage:

1、We focus on the R & D, manufacturing, marketing and service of industrial laser processing equipment more than ten years

2、We have a staff team which owns high-level culture and high-tech level,senior marketing management team,excellent engineering

and technical personnel, bridle-wise service engineer, forming a strong technical support system.

3、Our development system is perfect, adhere to indigenous innovation,brand management and spare no effect to create professional、superior、safe、normative and classic products. Not only meet the demands that customers on the scale, quality and efficiency, but also satisfy personalized design and manufacturing requirements.

2、We have a staff team which owns high-level culture and high-tech level,senior marketing management team,excellent engineering

and technical personnel, bridle-wise service engineer, forming a strong technical support system.

3、Our development system is perfect, adhere to indigenous innovation,brand management and spare no effect to create professional、superior、safe、normative and classic products. Not only meet the demands that customers on the scale, quality and efficiency, but also satisfy personalized design and manufacturing requirements.

Packing & Delivery

FAQ

Q1 :What are the primary products of your company?

A : different customized Laser welding machine and laser marking machine ect.

Q2: How to do control the quality when you produce laser equipment?

A : We introduce international advanced production technology, and strictly implement a series of measures of quality and cost control to ensure the quality of laser machines. In addition, all components are strictly inspected in accordance with

international standards before they are put into production.

Q3 : How can I know your machine is designed for my product?

A : You can send us samples of your product and we test it on machine.

Q4:How long is the delivery time?

A : The laser machines will be delivered to you within one month after the order is confirmed.

Q5 : Do you have a CE/ISO certificate?

A : Yes.

Q6 : If we do not know to use the machine, can you teach us?

A : Yes, we will, if you come to China, we will offer you free training until you can use machine freely.During installation, we will have our professional engineer to your country to train your stuff to use it.

Q7 : When the machine can't work well, what should I do?

A : 1. The engineer is online for 24-hours, they can check the problems and then give you solution way very soon.

2. All our machines have one-year warranty. If there is any problems of machine parts under " normal use", new machine parts will be sent to you but your side should pay the shipping cost.

3. Operation CD and manual will be offered along with machine,ensuring you can operate the machine easily.

A : different customized Laser welding machine and laser marking machine ect.

Q2: How to do control the quality when you produce laser equipment?

A : We introduce international advanced production technology, and strictly implement a series of measures of quality and cost control to ensure the quality of laser machines. In addition, all components are strictly inspected in accordance with

international standards before they are put into production.

Q3 : How can I know your machine is designed for my product?

A : You can send us samples of your product and we test it on machine.

Q4:How long is the delivery time?

A : The laser machines will be delivered to you within one month after the order is confirmed.

Q5 : Do you have a CE/ISO certificate?

A : Yes.

Q6 : If we do not know to use the machine, can you teach us?

A : Yes, we will, if you come to China, we will offer you free training until you can use machine freely.During installation, we will have our professional engineer to your country to train your stuff to use it.

Q7 : When the machine can't work well, what should I do?

A : 1. The engineer is online for 24-hours, they can check the problems and then give you solution way very soon.

2. All our machines have one-year warranty. If there is any problems of machine parts under " normal use", new machine parts will be sent to you but your side should pay the shipping cost.

3. Operation CD and manual will be offered along with machine,ensuring you can operate the machine easily.

Похожие товары

Высокое качество чистый натуральный черный глазый горох бобы из коровьего гороха органические черные белые бобы для продажи

20 077,26 ₽ - 30 115,89 ₽

Лидер продаж, Мембрана обратного осмоса Ro 2012-100, мембранный фильтр, цена ro 100 Gpd, детали фильтра для воды

3,55 $ - 3,69 $

Заводской экскаватор грязевой Ковш 2 М Рок ковш мини экскаватор аксессуары Наклонный ковш

Новая модель автомобиля, грузовика, автомобиля, фургона Toyota Corolla Cross 1.8l, бензиновая автоматическая коробка передач для экспорта из Японии

Китайские поставщики, самоклеящиеся 2 мм SBS, модифицированные асфальтовые кровельные мембраны с алюминиевой фольгой

NFM-H1080 автоматическая машина для ламинирования клея холодная и горячая текстурированная пленка Термическое ламинирование

91 850,00 $ - 92 620,00 $

Комплект кружевного нижнего белья из 2 предметов

2,75 $ - 3,29 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $