Профессиональные производители компании индивидуальный медицинский продукт пресс форма из АБС ПВХ ldpe сервис пластиковые детали пластмассовое литье под давлением

- Категория: >>>

- Поставщик: Suzhou FCE Precision Electronics Co. Ltd.Suzhou Ltd.

Сохранить в закладки 1600614408814:

Описание и отзывы

Характеристики

Why Choose Us

Products Description

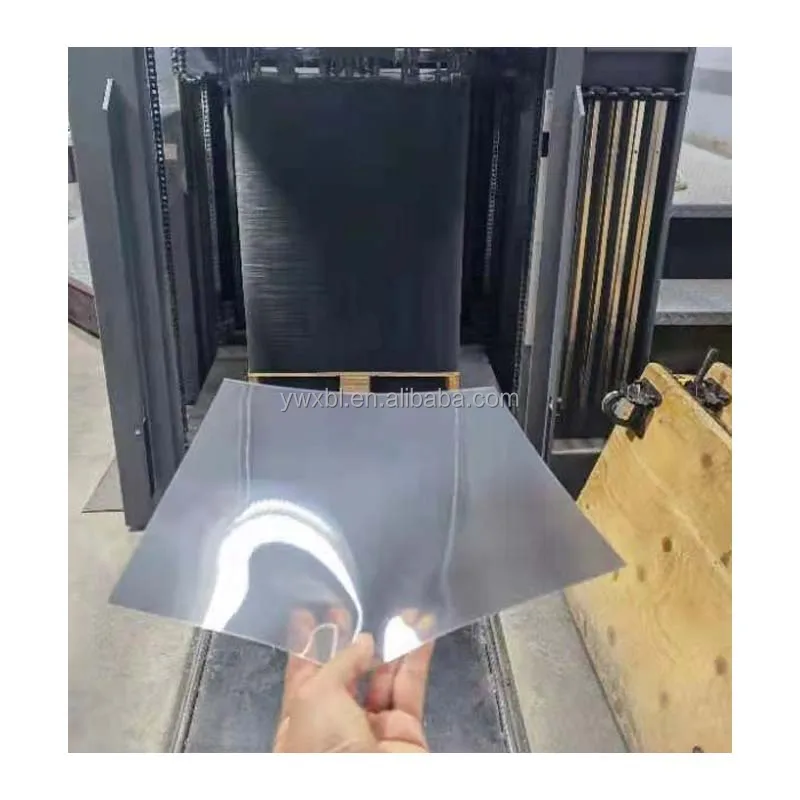

Product Description | ODM plastic injection molding |

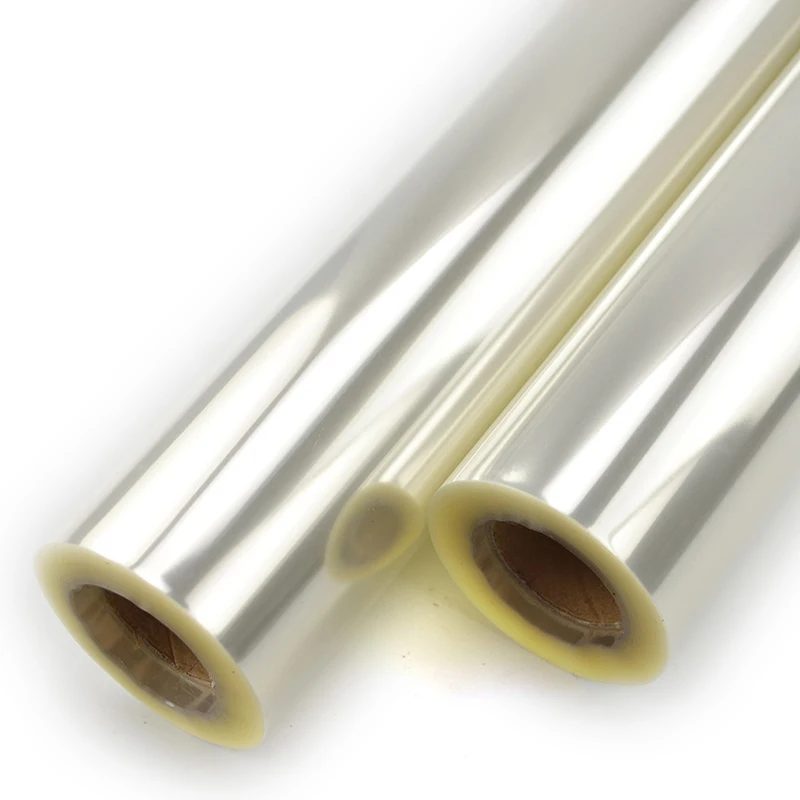

Plastic Materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO... |

Certificates | ISO9001 IATF16949 |

Other Process | Silicone Rubber over molding, LSR overmolding, Rubber molding |

Color | Per customer request |

Package: | Carton Box with protection material inside. |

Mold Lead Time: | T1, 4-7 weeks. Tf depends on product, normally take 2 weeks for fine tune. |

Experience: | 18 years specialize in plastic manufacture ODM |

Mold and Molding Tech. | In-Mold Decoration, Injection Molding, Over molding, Multi-K Molding, Stack Mold molding, RHCM Molding, Gas assistance molding, Interchangeable Mold, Collapsible Core Mold, Compression Molding, bottle injection and blow molding |

Mould Base: | Hasco LKM FUTA DME … |

Surface Finish: | Texture(MT standard), High gloss polishing |

Second process | Electroplating, Painting, hot stamping, printing, machining, assembly |

Cavity/Core Steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 … |

Hot/ Cold Runner | HUSKY, INCOE, YDDO, HASCO, DME, Masterflow, Mastip… |

Mould Life: | 30,000 to 1,000,000 Shots. |

Design Software: | CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA.... |

Equipments: | Plastic Injection Molding Machine from 35-3,000T Mold machine High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder… |

Company Profile

Welcome to FCE, Let us have a quick factory tour. We have been focusing on Plastic and metal parts manufacture for 18 years, Major markets are for Automobiles and appliances. We have four factories, integrated injection mold development, Molding production, silicone compression moulding, Liquid silicone injection molding, Metal stamping, CNC machining and assembly. Precipitated a strong specialist team from industrial design, mould manufacture, process engineering, material application.

Mold factory is armed by top brand machines of 5axis CNC, wire cutting, turning, EDM, grinding and so on. All of key components are made in house. Rich experience in mold technology of Multi-K, insert molding, IMD, stack tool, gas assistance. Through 3D cooling insert and copper insert application, significantly increased production efficiency. Also developed ripe experience on steel heat treatment, DLC coating for long life mold.

Injection molding factory has 64 sets molding machines. Tonnage range is from 35 to 3000. Could handle part weight from 0.2g to 3kg production. all of machine equipped with robot arms to ensure stable process and quality product.

Silicone factory owns 32 set compression molding machines, 6sets LSR injection molding machine. Cooperate with Apple, BMW for many years, market is expanded to over 50 countries.

Silicone factory owns 32 set compression molding machines, 6sets LSR injection molding machine. Cooperate with Apple, BMW for many years, market is expanded to over 50 countries.

All of above factories are certificated by ISO9001, IATF 16949. FCE strictly practice Non-disclosure agreement with each customer. Through Alibaba trade assurance order, 100% ensure good quality, on-time delivery, safe payment, Look forward to working with you, face the opportunities and challenges together!

Moulding Technology

Order And Process Flow

This is FCE way

* Start the quality from a good planning

* Set quality gate at each phase

* Advanced process to assure quality & traceability

* Closed loop Projection and Quality management

* Start the quality from a good planning

* Set quality gate at each phase

* Advanced process to assure quality & traceability

* Closed loop Projection and Quality management

Customer Photos

Certificates

FAQ

Q1. How do you ensure quality?

Risk order material in advance

By good APQP practice and proper monitor. We do feasibility, design, manufacture, trial run etc. phase gate management to control the quality in each phase.

Q2.How do you compress the lead time if urgent case?Risk order material in advance

Synchronous Engineering

Metal safe rough machining in advance

Q3.I have no 3D drawing, how should I start the new project?

Just give us you concept or own sample, we provide from concept to reality service.

Q4. Do you support post-sale service?

Defect parts free replacement

Q3.I have no 3D drawing, how should I start the new project?

Just give us you concept or own sample, we provide from concept to reality service.

Q4. Do you support post-sale service?

Defect parts free replacement

On line and on-site supporting

Free consulting

Q5. How could I pay them?

Paypal, Western Union, T/T, L/C are acceptable, so just let us know which is convenient for you.

Q6. Can I get discounts?

Yes, for big order, old customer and frequent customers, Will be reasonable discounts.

Q7. What's the payment term?

Normally 40% pay advance, balance the rest against to the shipment B/L.

Q5. How could I pay them?

Paypal, Western Union, T/T, L/C are acceptable, so just let us know which is convenient for you.

Q6. Can I get discounts?

Yes, for big order, old customer and frequent customers, Will be reasonable discounts.

Q7. What's the payment term?

Normally 40% pay advance, balance the rest against to the shipment B/L.

Похожие товары

Pn20 водопроводная труба синего цвета, полипропиленовая труба OEM, фирменные наименования с прайс-листом, таблицей размеров, полипропиленовые Трубопроводы из полипропилена

30,13-34,95 ₽

Нажимная опора для головки летательного аппарата, белая/черная, нейлоновая распорка для шестигранной печатной платы, отверстие 4,0 ММ, 4,8 мм, пластиковая распорка для пбц

1,15-5,74 ₽

Индивидуальная форма и размер прозрачная лазерная резка акрила

11,87-106,75 ₽

Простая необычная Антистатическая водонепроницаемая бумага с высокой прозрачностью

953,66-1 132,47 ₽

Zebulun 3D линзовидный Лист 75 LPI/0 58 мм толщина/Размер 710*510 см ПЭТ пластиковая УФ-печать для линзовидной печати

74,19 ₽ - 91,31 ₽

Пенопластовые аксессуары для вышивки вышивкой eva 3d пена для вышивки

38,65 ₽

Стеновые панели из искусственного камня и мраморный лист из ПВХ, Толщина 6 мм, 1,22*2,44 м

1 236,53 ₽ - 1 313,81 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $