Изолированная композитная сэндвич панель из стекловолокна GRP FRP для RV PU/XPS изоляция боковая панель

- Категория: Building Boards >>>

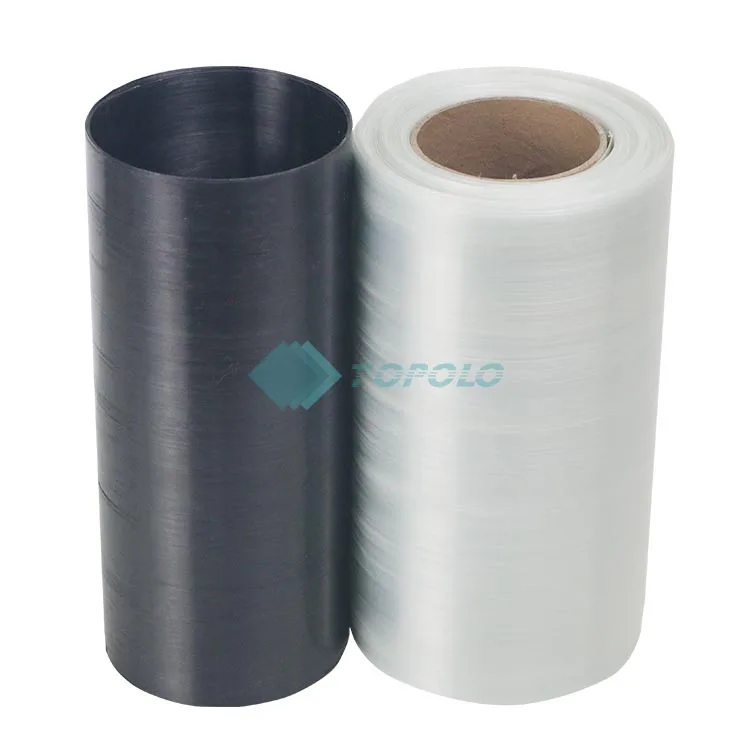

- Поставщик: Shanghai Topolo New Materials Co. Ltd.

Сохранить в закладки 1600617826933:

Описание и отзывы

Характеристики

Honeycomb structure combined with fiberglass skins results in strong, tough, and lightweight fiberglass honeycomb panels. The world-leading skin materials integration of honeycomb materials led to the birth of new materials. It minimizes handling operations and greatly decreases the production cost.

The Structure of Fiberglass Honeycomb Panels

The sandwich structure is a creative integration of skin materials and honeycomb core, making the thermoplastic composite panels much lighter and stronger. Composite honeycomb sandwich panels are composed of honeycomb cores and thermoplastic FRP laminates sheets (also referred to as “skins” or “sheets”). These thermoplastic sheets are laminated together at different angles, making the skin stronger. This is a wonderful structure offering strength-to-weight ratios much higher than traditional materials.

Honeycomb Types

The strength of the honeycomb panel is related to the shape of the raw material and the core material. The honeycomb shape can be hexagonal, rhombic, rectangular, etc. The honeycomb core not only saves material and is easy to process, but also enhances the strength of the sheet.

Specification | ||

Type | Fiberglass sheet + Honeycomb core +Fiberglass sheet | |

Width | 0.1m ~3m | |

Length | Custom-made | |

Width | 50mm~3000mm | |

Thickness | 9mm~60mm | |

Density | 80kg/m3~160kg/m3 | |

Core Material | PP/PC | |

Cell Diameter | 6mm, 8mm, 10mm, 12mm | |

Other properties | UV resistance, water resistance | |

Custom-made | Glue, non-woven Fabric | |

Fiberglass Honeycomb Panel Processing

The common method for sandwich panel molding is lamination, in which prepreg tape is cut and placed between two polished metal molds to form a composite product under heating and pressure. It is an early developed and matured process of composite materials. It is mainly used to produce composite panels of various specifications, with the characteristics of mechanization, automation, and stable quality.

Honeycomb Structure Forming Method

* Dry molding:

Though dry molding, the bonding strength between the honeycomb core and the panel can be increased to more than 3MPa. The honeycomb surface is smooth and flat. Every process in the production is easy to check so that the quality is easy to control.

* Wet molding:

The production cycle of wet molding is short. It is most suitable for special-shaped products such as spherical surfaces and shells.

Application

Due to the excellent properties of the composites honeycomb sandwich panel (thermoplastic sandwich panel), it has been used widely in:

Transportation

Dry van body, recreational vehicle floor.

Campers

Fiberglass honeycomb panels are especially suitable for small teardrop RVs. It minimizes body weight.

Building

Building formwork, various ground skid panels.

Sporting goods

Pickle rackets, skateboards, hulls, ping pong tables, etc.

Choose Fiberglass Honeycomb Panels at TOPOLO

TOPOLO design and manufactures honeycomb sandwich panels and thermoplastic composite panels with two kinds of different skins: CFRT (continuous fiber-reinforced thermoplastic) skin and FRP skin sandwich panels.

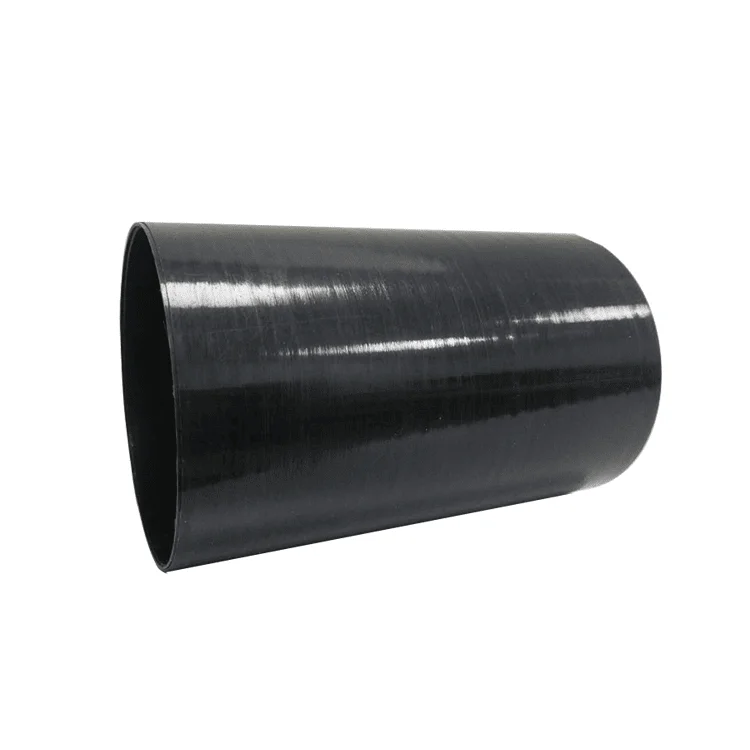

Carbon Black Honeycomb Panel

Anti-Skid Sandwich Panel

Honeycomb Formwork Panel

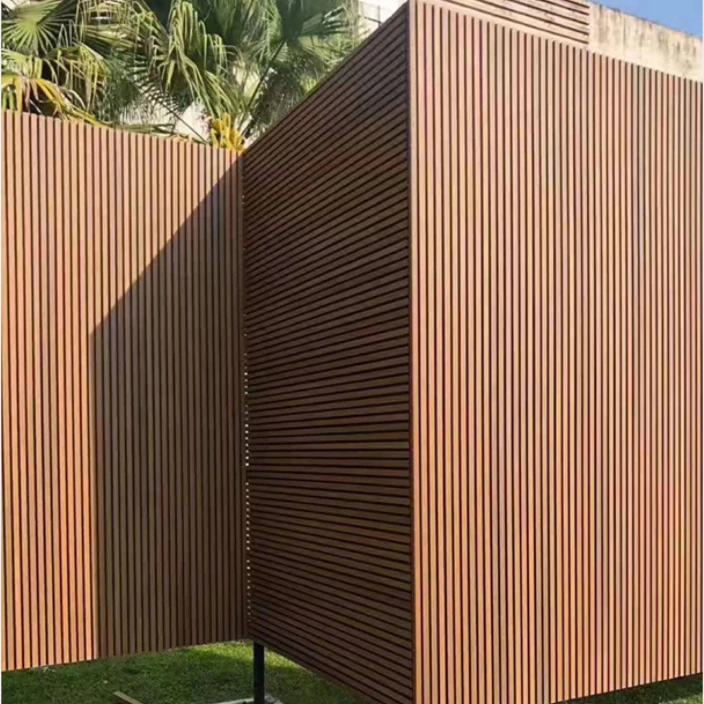

Wood Grain Honeycomb Panel

Our fiberglass honeycomb panels have the following advantages:

*Low density: Since PP/PC honeycomb is a porous material, the entire panels are lightweight.

*Good flatness and rigidity: Using continuous glass fiber thermoplastic sheet as skin.

*Good sound insulation and heat insulation performance: good sealing performance greatly limits the spread of heat and sound waves.

*Shock absorption: Dense honeycombs and high-strength FRP skin disperse pressure.*Good flatness and rigidity: Using continuous glass fiber thermoplastic sheet as skin.

As a professional composite sandwich panel supplier, TOPOLO can supply:

*Panel skins of CFRT or FRP sheets are available from 2 to 9 layers.

*A wide range of up to 3.2m.

*The customized thickness of the honeycomb core is from 8mm to 50mm.

*A wide range of up to 3.2m.

*The customized thickness of the honeycomb core is from 8mm to 50mm.

Choose TOPOLO Fiberglass Sandwich Panels

TOPOLO fiberglass sandwich panels factory covers an area of tens of thousands of square meters, with a daily production area of more than 10,000 square meters. Our FRP panels are very popular in the international market, and currently sell well in Europe, South America, North America, Middle East, Central Asia, Southeast Asia, Africa and other markets.

Professional International Sales Team

Professional international sales team – English, French, Russian, Spanish, Portuguese, etc., make our communication unimpeded, from pre-sales product consultation to after-sales logistics services, to provide you with professional solutions.

Похожие товары

OEM принимаем заказы полимраморный лист УФ

4,50 $ - 8,50 $

MT-4482 поставка из Китая 19 дюймов Тип 1U патч-панель пустой щетка

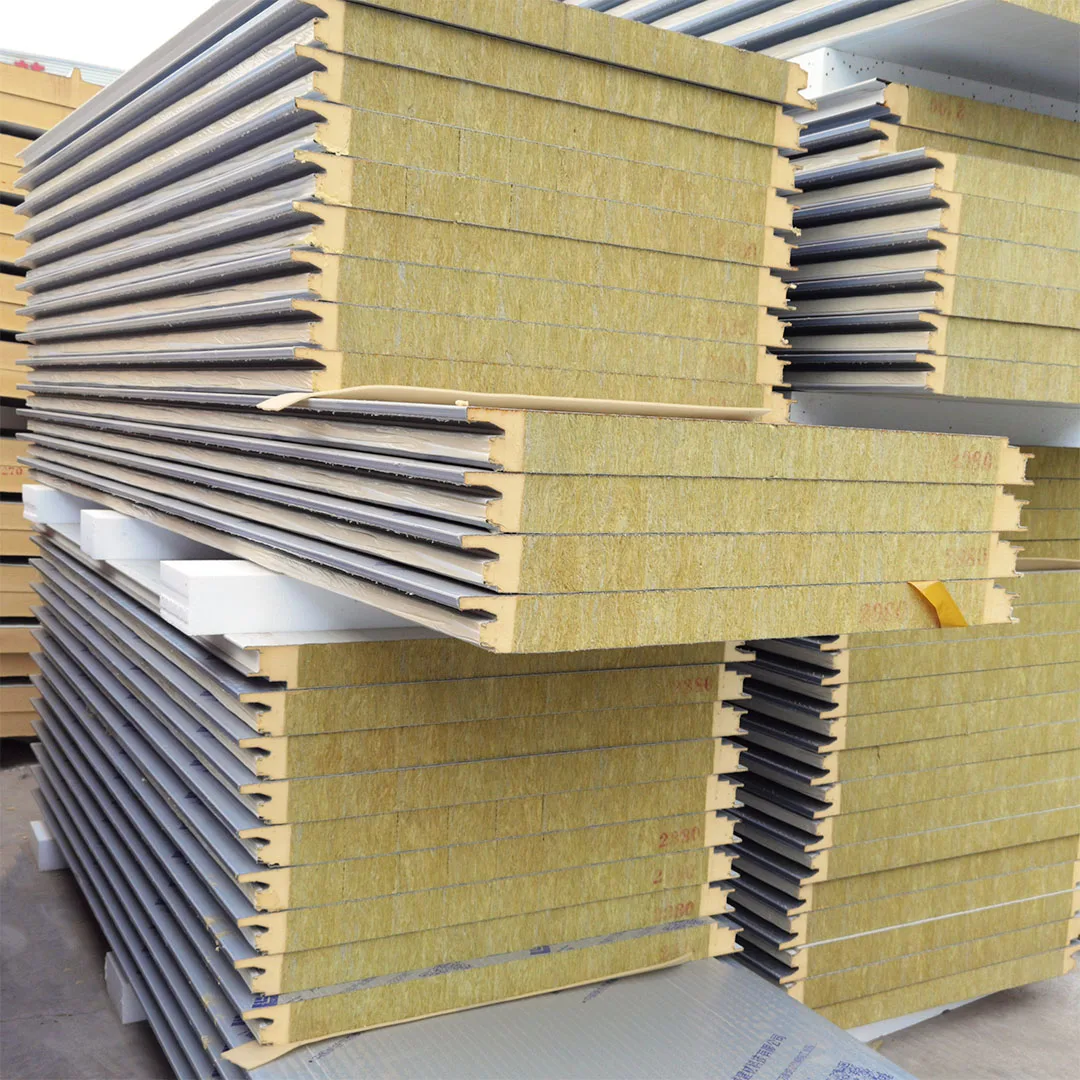

Огнестойкая стеновая сэндвич-панель из минеральной ваты по лучшей

8,90 $

Прочная наружная Высококачественная звукозащитная стеновая панель из минеральной

5,40 $ - 6,60 $

Фабричное внутреннее украшение древесно-пластиковый композитный наружный экструзионный композит WPC Co декоративное покрытие для интерьера облицовка стеновой

Огнестойкая древесно-пластиковая композитная коэкструзионная облицовка Наружная стеновая панель WPC наружная

3,79 $ - 4,35 $

Горячее прессование обработанная стеновая панель деревянно-пластиковая композитная Водонепроницаемая из

5,99 $ - 7,99 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $