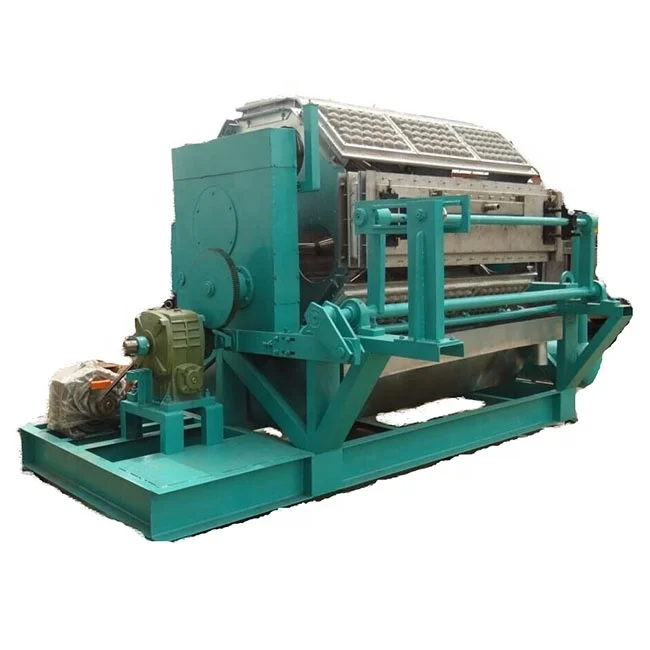

Автоматическая сушилка для бумажных целлюлоз яиц плоских лотков Индонезия Филиппинская Малайзия Индия 2000 7000 штук в

- Категория: >>>

- Поставщик: Qingdao Perfect Equipment & Parts Co. Ltd.

Сохранить в закладки 1600618624458:

Описание и отзывы

Характеристики

India Turkey Indonesia Malaysia Philippine 2000-7000 pieces per hour auto brick dryer paper pulp egg holder flat tray making machine

Capacity: 2000-7000 pieces/hour ( 30 caves egg tray, 70-100 GSM per PC)

4 sides/8 sides/12 sides, each side install 3/4/5/6 pieces paper pulp egg tray forming molds

Working speed: 18-21 times/min

Machine body: stainless steel

PFK AB series automatic egg tray production line with brick drying oven is used to recycle the waste paper and old carton box into paper egg tray, apple trays, coffee cup holder trays and other shape paper packing trays which height is less than 7cm, fully stainless steel machine body, and high working speed, matched with power saving motor, guarantee the top performance of the production.The brick drying oven has very high drying efficiency, and more than 10 years life span. The brick drying oven automatic egg tray production line with brick dryer already been exported to Russia, USA, Ukraine, Egypt, Algeria, Brazil and Turkey,India, Indonesia, Pakistan, Philippine, Saudi Arabia,Venezuela,Mexico, and won high reputation among our clients.

Due to the whole production of the egg tray do not cause any pollution, all waste paper and waste water are recycled in the production process, it is a good investment for the buyers who want to recycle the waste paper and old cartons.

You can also produce other paper trays by changing moulds through this model machine, like apple tray, shoe tree.

Model | A2000B | A3000B | A4000B | A5000B |

Capacity | 2000-2500 pcs/hour | 3500-4000 pcs/hour | 4000-4500 pcs/hour | 5000-5500 pcs/hour |

Main Features of our auto egg tray making machine with brick dryer

1) Excellent design for the whole line, covering smaller area

2) Using energy saving motors, reduce the power consumption greatly

3) Egg tray forming machine tanks, hoods, and main parts use Stainless steel material, has longer life span

4) Bearing and gear boxes, mainly electric parts use World or China famous brands, gurantee the quality of the machine

5) The metal dryer has 2 layers, iron plates inner side, and outside covering temperature keeping plate, has good drying performance

Egg tray forming machine pulp tank, pulp tube

Stainless steel material, all the parts which are contact with paper pulp of the egg tray machine are used stainless steel material

Egg tray forming machine frame

The heavy base of the egg tray machine guarantee the steady performance at high speed running condition

All metal parts of the frame are produced by ourself, can contral the quality from material purchasing to final forming strictly.

Egg tray forming moulds

Can chose plastic material or aluminum material

The moulds are produced based on buyers sample or drawing

Egg tray drying metal dryer is optional

Multi-layer metal drying oven

Can chose diesel natural gas steam thermal oil as heat source

Working power can chose 220V/380V/420V

Pre-Sales Service

* Reply your questions about egg tray making timely

* Provide professional suggestion and design based on your budget and workshop sizes

* Visit our factory and domestic client's production site to understand the production.

After-Sales Service

* Engineers come to install the egg tray production line

* Trainning how to operate and maintain the whole line

* Technicial support if questions during your production

Packing of the egg tray making machine

Plastic film wrap the egg tray forming machine

Pumps and small parts will be loaded into container directly.

Delivery of brick dryer egg tray production line

1*40"HQ container load the whole egg tray machine with brick dryer system

Delivery from Tianjin or Qingdao seaport

45 working days after received 30% prepayment, 70% before delivery by T/T

Shoes stretcher machine

800-1000 pieces/hour shoe tree

Integrated pulping system

Very popular in India market

Low investment, small covering area, easy to install easy operate

Fruit basket tray machine

500-600 pieces/hour fruit trays

Integrated pulping system

Used to make egg box tray, coffee cup holder tray, fruit vegetable containers tray with big height

Apple tray making machine

2800-3200 pieces/hour apple tray

Automatic rotary paper pulp tray molding forming

Match with metal dryer, improve the apple tray's production greatly

Похожие товары

Кресло для кемпинга

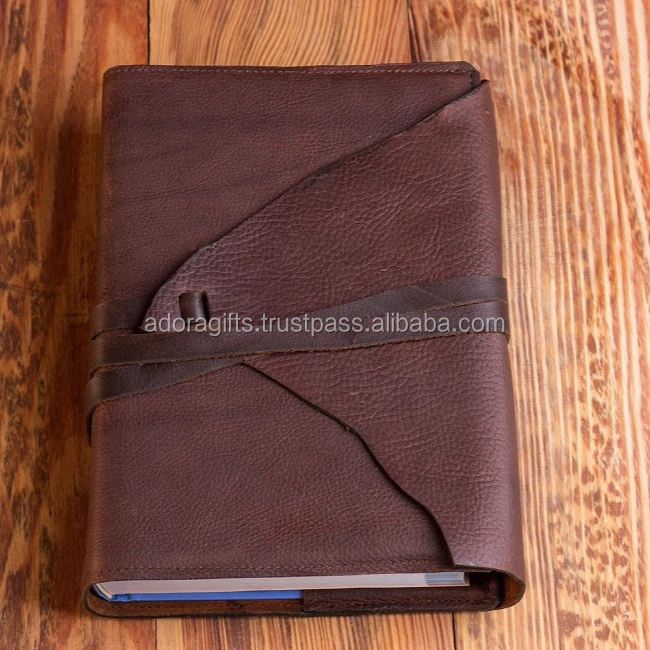

Чехол для Библии и Корана

Катушечный провод, предохранительный элемент Micro Glass, Тип предохранителя 5A 6.3A 250V

DO-510 портативный тестер качества воды ЖК-дисплей Счетчик растворенного кислорода

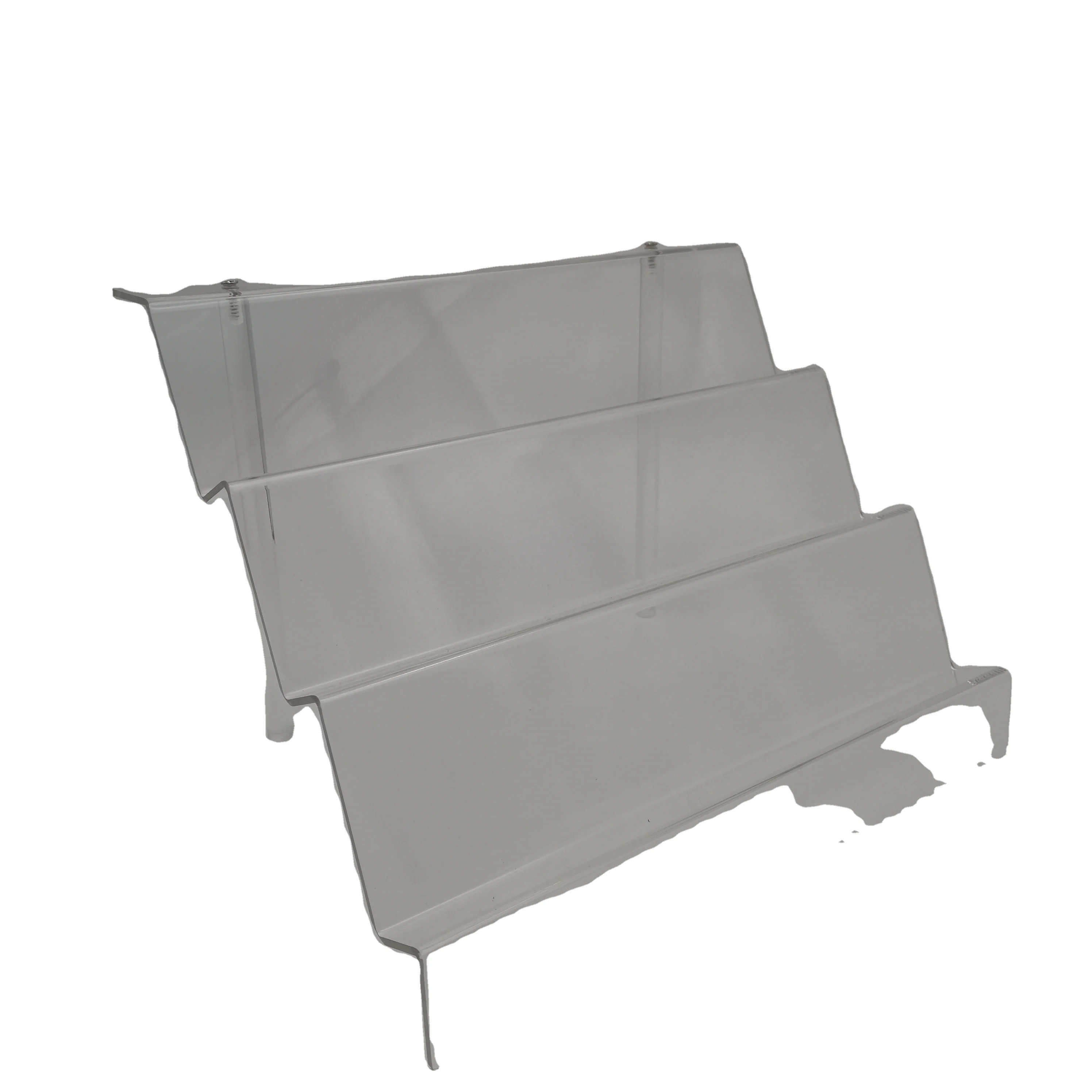

Выполненный по индивидуальному заказу 3 шаг прозрачный Витринный Шкаф для зажигалок Zippo, акриловый дисплей подставка Зажигалка поставщик

Hanzhinail 2022, без запаха, EMA mma, бесплатный мономер, 1 унция, Профессиональный акриловый порошок для нейл-арта, прозрачный, оптовая продажа

200 Вт поставщик светодиодный солнечный уличный свет с ветровой турбиной светодиодный уличный свет Солнечная Панель 6 В/18 В. Монокристаллический

Новые поступления

Новинки товаров от производителей по оптовым ценам