Горячая Распродажа 900 bph 5 галлонов бутылка автоматическая машина для розлива

- Категория: Packaging Machines >>>

- Поставщик: Zhangjiagang Sheenstar Technology Co. Ltd.

Сохранить в закладки 1600627310063:

Описание и отзывы

Характеристики

Hot sale 900 bph 5 gallon bottle automatic water filling machine line

Our bottled drinking water production line mainly consists of 5 parts. They are respectively:

1.Water Treatment System

2.Plastic PET preform bottle blowing machine

3.5 gallon water washing filling capping 3 in 1 machine

4.Automatic Labeling Machine

5.Bottle Packing Machine

That is to say, this line from the raw water treatment to the bottled water packaging , is a complete automatic production line, it can well meet customer needs. We also design a reasonable plan for you to achieve higher production efficiency.

Machine Parts

Name: Water Treatment System

Material: 304 Stainless steel

1, continuous operation, product quality and stability.

2, no need to use acid-base regeneration.

3, save the recoil and wash water.

4, the yield rate (yield can be as high as 95%).

5, no reclaimed wastewater, no sewage treatment facilities.

6, without the need for acid and alkali dilute acid and alkali transport equipment.

7, the use of safe and reliable.

Machine Parts

Name: Plastic PET preform bottle blowing machine

1. Controlled by MITSUBISHI touch screen computer. Operate consistently and simply.

2. Pneumatic elements from FESTO (German) and SMC (Japan)

3. Energy-saving and environmentally friendly design. Mechanical units are compact and rational.

4. Malfunction alert and diagnostic units allow easy maintenance.

5. Suitable for manufacturing a variety of PET bottles: mineral water bottles, edible oil bottles, soda bottles, medicine bottle, cosmetics bottles etc..

Machine Parts

Name: 3-in-1 Water Filling Machine

This series of mineral Water Filling Machine are applied to the production of pure water, mineral water, it integrates bottle washing, filling and capping into one body of this machine. It is very convenient to change bottle size by means of advanced bottle conveying technology--bottleneck clamping & bottle suspending technology.

Machine Parts

Name: Automatic Labeling Machine

1. Whole machine adopt qualified stainless steel and good-quality of aluminum alloy.

2. The label roll frame of shrinkage film with adjustable device.

3. Simply installation, then can convenient for square and round bottle.

4. No need of instrument, rotary mechanism is convenient to adjust, apply to different bottle type.

5. Unique sleeve labeling method, adopt pressing sleeve labeling method

6. Control the feeding system automatically, and flat the shrinkage film and adjust strain simultaneity.

7. Unique design knife plate, in the determined range, can change the knife base. Knife changing quickly and conveniently.

Machine Parts

1.sealing and protect the operato meanwhile.

2.Double size fan carrying system ensur the perfect of sealing.

3.Imported AC contractor, the temperature be controlled by automatic.

4.Imported frequency converter, stepless speed regulating.

5.Super cooling system to ensure the perfect shape of products quickly ofter shrinking.

6.The control panel be operated with safe and simple.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packaging | ||

Size | 2.5(L) * 1.89 (W) * 2.13 (D) | |

Weight | 2.2 T-9T | |

Packaging Details | The normal package is wooden box. If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. | |

Delivery | ||

Port | Shanghai | |

Transportation | Sea and Overland transportation | |

Delivery details | The supplier will deliver the goods 100 days after the advance payment to the account (the date of the telegraphic transfer certificate) and the contract to be effective. | |

Q1:What kinds of product you supply?

A1:Bottled water whole production line, 5 gallon drink water production line , Juice, carbonated beverage,Packing system;PET bottle blowing machine;lnjection molding machine.etc.

Q2:The minimum capacity of the machine you offer?

A2:2000 bottles per hour

Q3: if our bottle size changes then can we also change the machine adjustments according to our new bottle?

A3:Yes, you can add a change part.

Q4: Semi-automatic or fully automatic?

A4: You can choose according to your needs.

Q5: If I want to buy a machine, what information do I need to tell you?

a. What kind beverage you want to produce?

b. bottle volume? 250ml, 330ml, 500ml, 750ml, etc.?

c. Producing capacity requirement? How many bottles per hour?

d.Raw water analysis report .

e.Voltage and altitude.

Похожие товары

Оптовая продажа с завода автоматическая машина для розлива вина виски водки сока

Одобренная CE термоусадочная упаковочная

Полностью автоматическая упаковочная машина, целлофановая упаковочная машина BOPP в продаже

Фармацевтическая небольшая блистерная упаковочная машина Dpp80 для

Автоматическая Подающая упаковочная палочка горизонтальная машина для упаковки табака с мелким

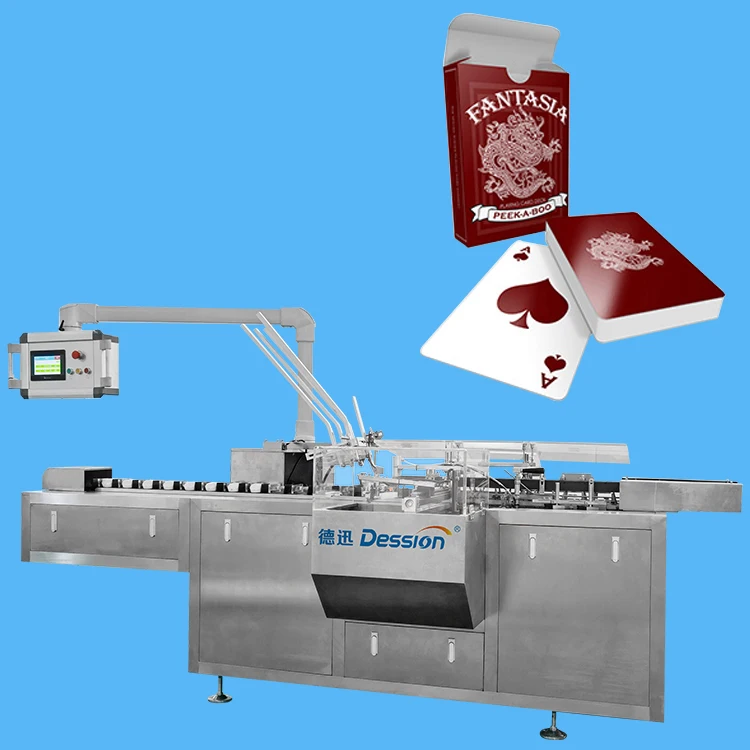

Горячая Распродажа автоматическая упаковочная машина для покерных карт игровая картонных коробок упаковки

GSS 1-10L ручная машина для розлива жидкостей химической

Новые поступления

Новинки товаров от производителей по оптовым ценам