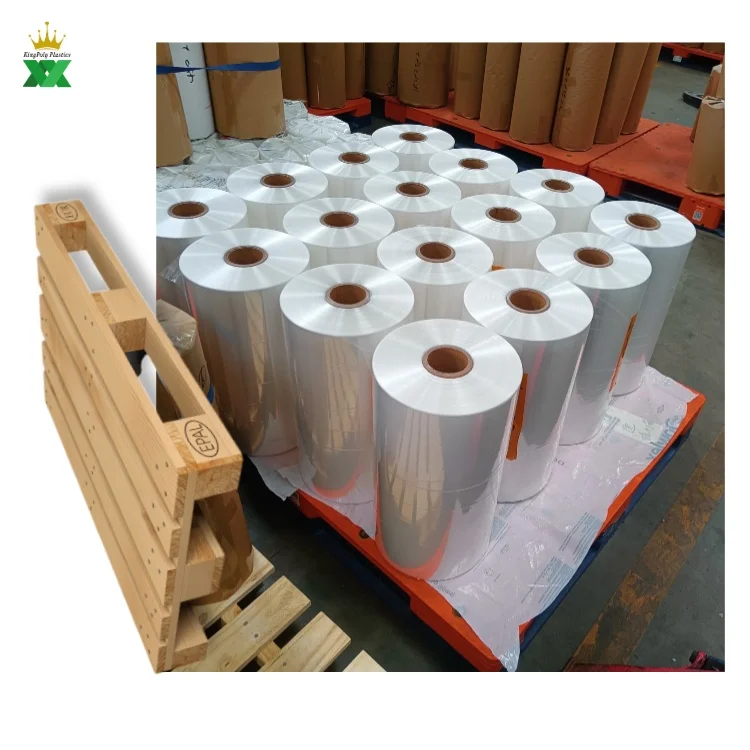

Устойчивая термо ламинатная пленка BOPP для центральных складок

- Категория: >>>

- Поставщик: Foshan Shunbaoli Plastic Products Co. Ltd.Foshan Ltd.

Сохранить в закладки 1600631136479:

Описание и отзывы

Характеристики

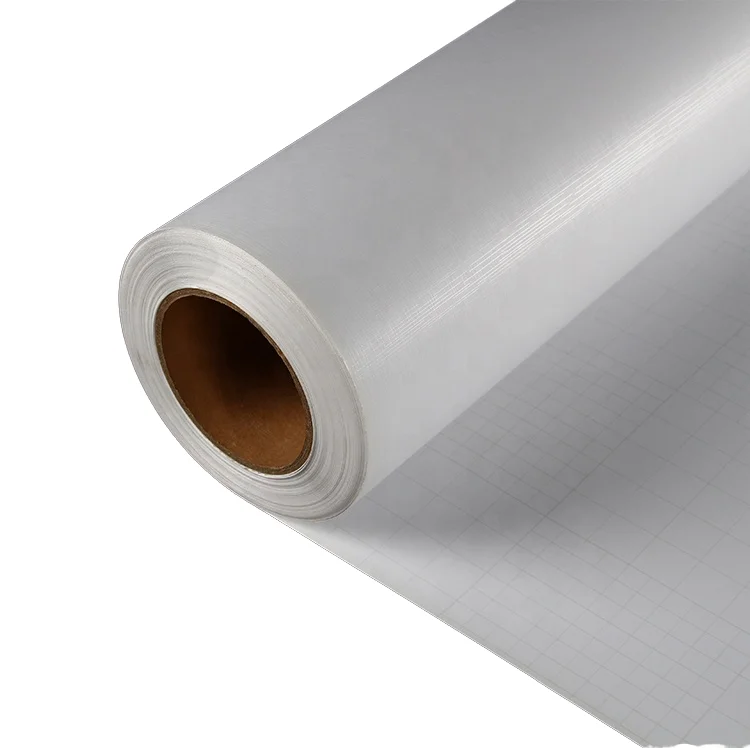

Pure white 35mic Clear Laminate Roll BOPP PVC Thermal Lamination Film With center folded type

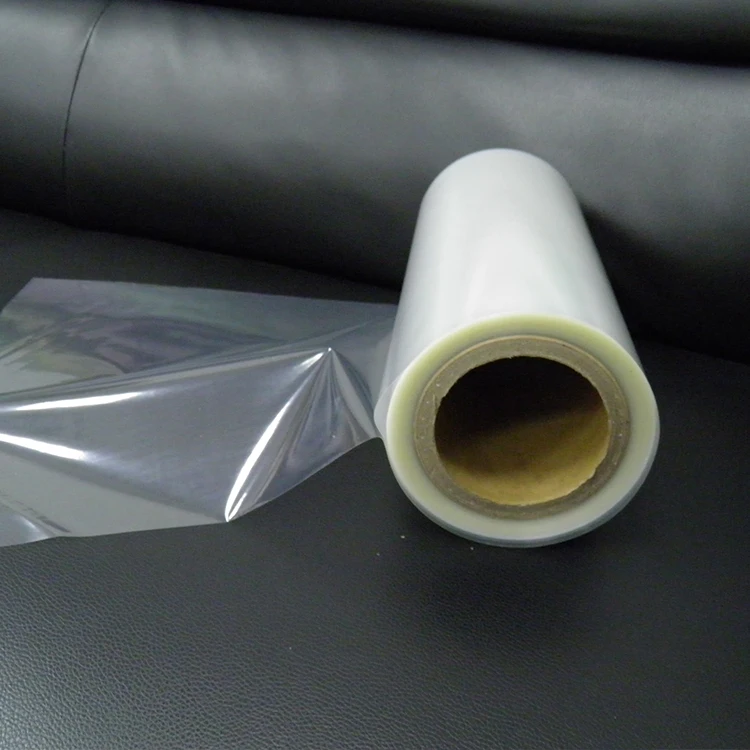

- PVC Thermal Shrink Film: A film that shrinks when exposed to heat, commonly used for packaging and insulation.

- PVC Cryo Shrink Film: Designed to shrink at lower temperatures, suitable for applications requiring cold shrinkage.

- PVC Filmic Labels: Thin, flexible PVC films used for creating durable labels.

- PVC Tubular Shrink Sleeve: Tubular form of shrink film that can be slipped over an object for a seamless, custom fit.

- PVC Shrink Film Roll: Available in rolls, used for wrapping and packaging applications.

- PVC Heat Shrinking Cover: A cover that shrinks upon heating to provide a tight, protective layer.

- PVC Protective Shrink Film: Used to protect items from damage during shipping and storage.

- PVC Shrink Film for Beverage Packaging: Specifically designed for the packaging of beverages, providing a tamper-evident seal.

- PVC Shrink Film for Cosmetic Packaging: Ideal for the cosmetic industry, offering a high-quality finish and secure closure.

- PVC Film for Pharmaceutical Packaging: Meets the standards for pharmaceutical packaging, providing a secure and tamper-resistant seal.

Width | 20mm-1800mm | Tensile strength | In transverse direction ≥50 Mpa |

Thickness | 13um-100um | In machine direction ≥45Mpa | |

Shrinkage rate | In transverse direction 5%-55% | Breaking elongation | In transverse direction ≥50% |

In machine direction 10%-55% | In machine direction ≥70% | ||

Shrinkage temperature | 90°C-150°C | Tearing strength | In transverse direction ≥45KN/m |

Transparency | ≥95°C | In machine direction ≥60KN/m | |

Specific weight | 1.40g/cm3 |

|

|

#Beverage Label Shrink Specifications:

Transverse Direction (TD) Shrink: 50-52%

Machine Direction (MD) Shrink: 2%

In the world of beverages, presentation matters just as much as the taste. Our shrink specs, tried and tested,

have proven highly effective in manufacturing and applying shrink film labels to beverage containers post-printing.

By employing a TD shrink rate of 50-52%, the film wraps snugly around the bottles when heated. This doesn't just offer label safeguarding,

but also bestows the container with a visually pleasing aesthetic. With the MD shrink maintained at a minimal 2%, we ensure no significant distortion occurs,

keeping your brand's image intact.

#Product Packaging Shrink Standards:

Transverse Direction (TD) Shrink: 50%

Machine Direction (MD) Shrink: 25%

Different products require different packaging solutions. Our shrink specs cater to a wide range of products. Utilizing a TD shrink ratio of 50%,

the film provides a secure wrap for your products, shrinking in the transverse direction during the heating process for the perfect fit. Meanwhile,

the MD shrink is elevated to 25%, offering effective reduction in package size while still providing a neat, tightly-sealed appearance.

Every customer's requirements are unique, and so are the application scenarios. To address these, we provide tailored shrink film parameters and solutions.

Rest assured, we're here to address all your queries and needs. Feel free to reach out to us anytime.

#Packaging Materials #Stretch Hood Film #Plastic Bag #Stretch Film Wholesale #Wrapping Film

- Q: What is plastic film printing?

A: Plastic film printing is a process that involves printing patterns or text on a plastic film using special inks. It involves various stages, including plate making, blowing, corona treatment, printing, laminating, cutting, heat sealing, and bag making. - Q: What are the characteristics of ink for plastic printing?

A: Inks used for printing on plastic are primarily made up of synthetic resin, organic solvents, and pigments. These inks exhibit excellent print adaptability, strong adhesion, and quick-drying properties. - Q: How should I select a binder for printing ink on a plastic film?

A: There are several methods to choose the binder for printing ink. These include using resin that is the same as the substrate or can dissolve the substrate material, using an ink binder that can chemically react with the substrate, or using a binder that can form a film layer similar to the surface of the substrate. - Q: How do pigments work in inks?

A: The pigment in the ink determines its color; the amount of pigment used determines the concentration of the ink; and the way the pigment is used also affects the drying time of the ink. - Q: What is surface and reverse printing?

A: Surface printing refers to the process of printing on the surface of the plastic film and then undergoing subsequent processes such as bag making, resulting in the image or text being displayed on the surface of the final product. In contrast, reverse printing involves transferring the ink inside a transparent material, allowing the right image to appear on the front side of the material. - Q: What is the role of a solvent additive?

A: The role of a solvent is to dilute the viscosity of the ink, optimize its flow and dispersion, and control the ink's rate of evaporation to make it more suitable for printing. - Q: What is the role of a binder in printing ink?

A: The binder is a viscous,sticky fluid that serves as the carrier for the pigment. It mixes and binds the powdered pigment and other solid particles to allow them to adhere to the printed product. - Q: How should one choose the printing method for plastic films?

A: There are several printing methods for plastic films, such as rotary gravure printing, screen printing or flexographic printing, and the choice should be made based on specific printing requests and conditions. - Q: Why should plastic films be treated prior to printing?

A: Due to the poor affinity between the plastic substrate and the ink and the lack of porosity in plastic substrates to absorb the ink vehicle, the plastic films need to be treated prior to printing to ensure a good adhesion with the ink.

Похожие товары

Китайская фабрика LLDPE стрейч пленка/оберточная пленка для ручного и машинного использования

Прозрачная перекрестная пленка холодного ламинирования ПВХ защитная

PVA материал экологически чистая Водорастворимая пленка для стирки моющее средство капсула 3 в 1 соуса

Китай высокое качество Водорастворимая пленка для стирки

Прозрачная текстурированная ламинированная пленка глянцевый ламинированный лист размер А4 А3

Биоразлагаемая бумажная герметизирующая пленка на заказ рулон одноразовой пузырьковой упаковки для чая полипропиленовая

Изготовленная на заказ теплопередающая пленка ПЭТ гидро для переноса воды печать

Новые поступления

Новинки товаров от производителей по оптовым ценам