GT5 12 высокоскоростной станок для вытягивания и резки стальной

- Категория: Metal Straightening Machinery >>>

- Поставщик: Langfang Runsun Intelligent Technology Co. Ltd.

Сохранить в закладки 1600633543340:

Описание и отзывы

Характеристики

Product Description

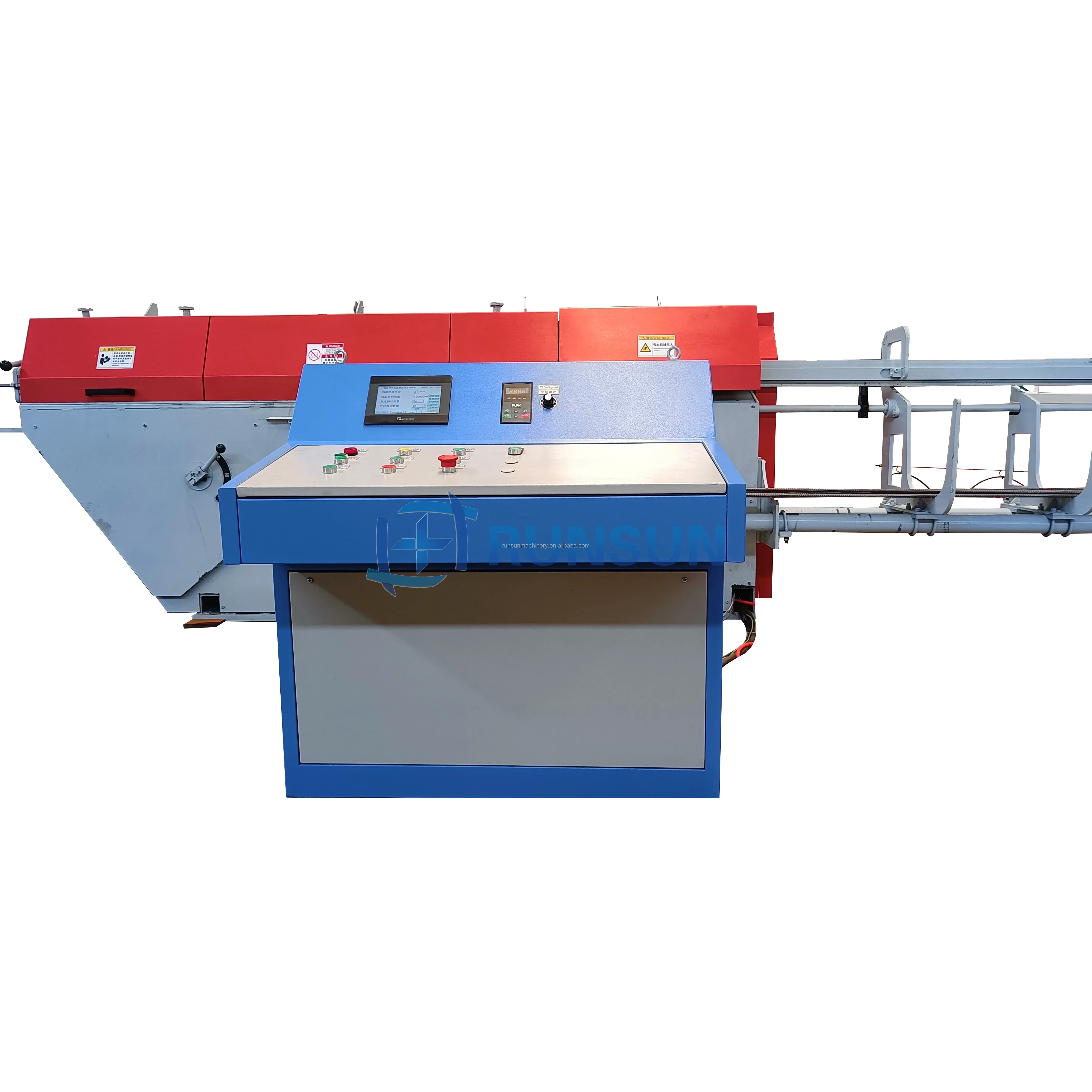

GT5-12 High Speed Steel Wire Straightening and Cutting Machine

GT Series High Speed Steel Wire Straightening and Cutting Machine used for straighening and cutting 5-12/6-12/8-14/10-16mm hot-rolled and cold rolled steel coil wire and deformed rebar. mostly used in steel mesh produce plant, precast concrete component produce facotry, normal building project, construction, tunnel, bridge, dam, high-speed road, High-speed train and so on.

- Working Speed: 70-150m/min

- Servo Motor Cutting Mode

- 12m Rebar Collect Stacker

- Power: 30+7.5KW

- Servo Motor: 7.5KW

- Control by Siemens PLC

- Cover: spraying plastic and stoving varnish

Main Technical Specification:

- Working Capacity: 5-12mm- Working Speed: 70-150m/min

- Servo Motor Cutting Mode

- 12m Rebar Collect Stacker

- Power: 30+7.5KW

- Servo Motor: 7.5KW

- Control by Siemens PLC

- Cover: spraying plastic and stoving varnish

Working Vidoes

Technical Specification

Model | GT5-12 |

Applicable Industries | Building Material Shops, Manufacturing Plant, Retail, Construction works , Energy & Mining |

5Working Capacity | 5 - 12 mm, Cold Rolled & Hot Rolled Round Bar/Deformed Rebar |

Finish Product Length | 0.6 - 12m, Adjustable OR customized |

Length Tolerance | ≤±1 mm |

Straightness | ≤2mm/m |

Working Speed | 70-100-130 m/min, Max. 150m/min |

Straightening Mode | Rotating Straightening Drum |

Wire Feeding Mode | Electric Motor |

Wire Cutting Mode | Servo Motor Cutting |

Control Mode | PLC (Siemens) & Servo Motor System |

Total Motor Power | 30+7.5 KW |

Servo Motor Power | 7.5 KW |

Electric capacity | ≥20KVA |

Power Supply Line | Cross-sectional Area: 6mm2 ; Material: Copper Material |

Air consumption | Working Pressure 0.6MPa, Flow Rate 18m3/h(0.3m³/min) |

Voltage | 3 Phase, 380V 50Hz or Customized |

Dimension(L*W*H) | 3200*850*1200mm |

Weight (KG) | 5500kgs |

Warranty | 1 Year |

Key Selling Points | Long Service Life |

Technical Advantages

1. Suitable for straightening and cutting cold-rolled round bar/ribbed bar, hot-rolled round/ribbed bar.

2. Intelligent control: The machine is controlled by PLC (Siemens),touch screen (Weinview) and servo motor (EURA Drives servo). Easy operation and working reliable

3. Low failure rate: Due to the fine processing of parts and strict quality control, after installation and debugging, under normal working conditions, it can maintain trouble-free operation for a long time.

4. World Advanced & Leading technology: Machine straightening and cutting technology

5. There are four working speed: 70m/min, 100m/min, 130m/min and 150m/min, Normally working speed: 130m/min, if you finish product length less than 2m, suggest 70-100m/min. Max. Working speed: 150m/min

6. High cutting accuracy: length tolerance: ≤ ±1mm

7. High straightness: ≤ 2 mm/m

2. Intelligent control: The machine is controlled by PLC (Siemens),touch screen (Weinview) and servo motor (EURA Drives servo). Easy operation and working reliable

3. Low failure rate: Due to the fine processing of parts and strict quality control, after installation and debugging, under normal working conditions, it can maintain trouble-free operation for a long time.

4. World Advanced & Leading technology: Machine straightening and cutting technology

5. There are four working speed: 70m/min, 100m/min, 130m/min and 150m/min, Normally working speed: 130m/min, if you finish product length less than 2m, suggest 70-100m/min. Max. Working speed: 150m/min

6. High cutting accuracy: length tolerance: ≤ ±1mm

7. High straightness: ≤ 2 mm/m

Recommend Products

Похожие товары

Машина для выпрямления стальных труб для теплиц, машина для выпрямления труб, машина для удаления ржавчины

1 399,00 $ - 1 599,00 $

Деформированная машина для выпрямления арматуры удаления

Практичный и доступный инструмент для выпрямления труб из нержавеющей

290,00 $

Стальной выпрямитель Decoiler и 2 в 1 стальной для листовой жести с выпрямителем прессовым штамповочным

2 000,00 $

Автоматическая машина для выпрямления и резки арматуры/стальная проволока механического

Автоматический сервопривод с ЧПУ для рулонного прессования рулонной

2 000,00 $

Б/у машина для выпрямления и резки проводов сварочного

800,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $